Supporting device for steel structure house construction

A supporting device and steel structure technology, applied in the direction of pillars, buildings, building structures, etc., can solve the problems that the supporting device cannot be adjusted to the desired height, the fixing effect of the supporting device is not ideal, and the safety of construction personnel cannot be guaranteed, etc., to achieve Diversified structures, increased strength, and a wide range of practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

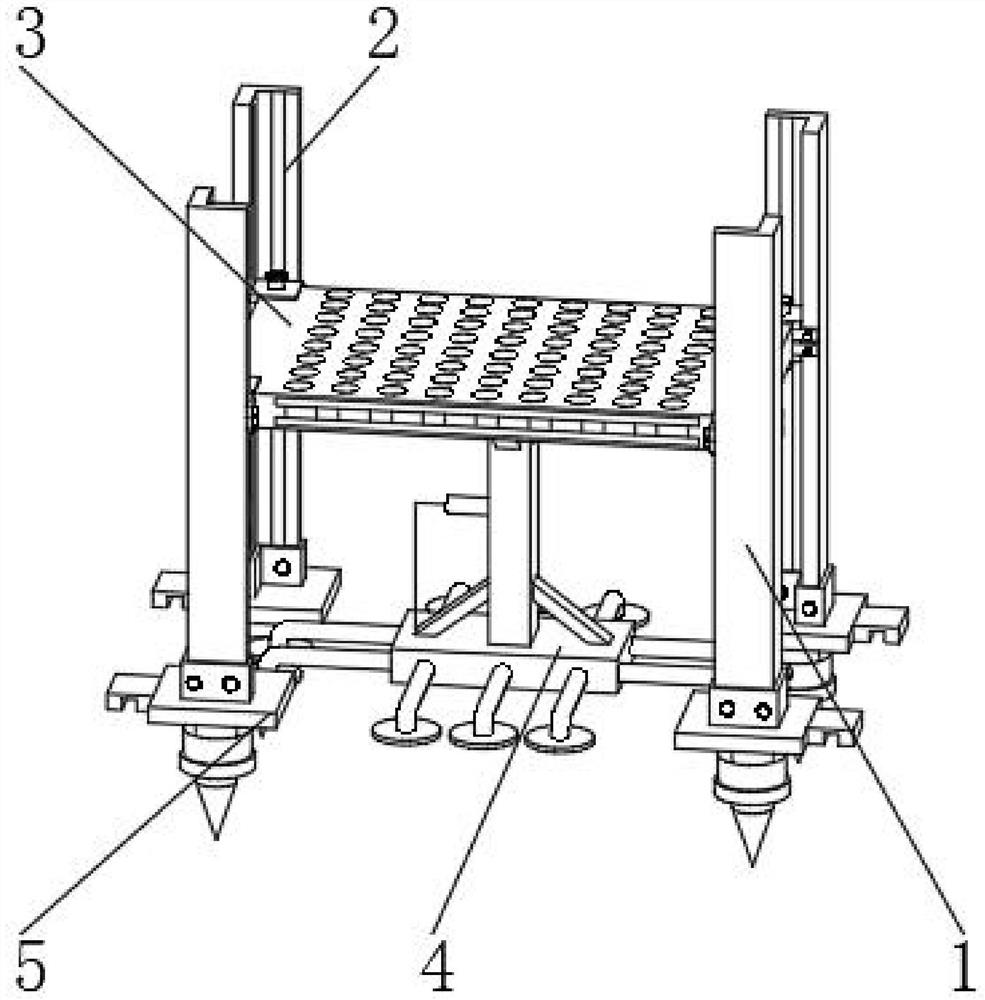

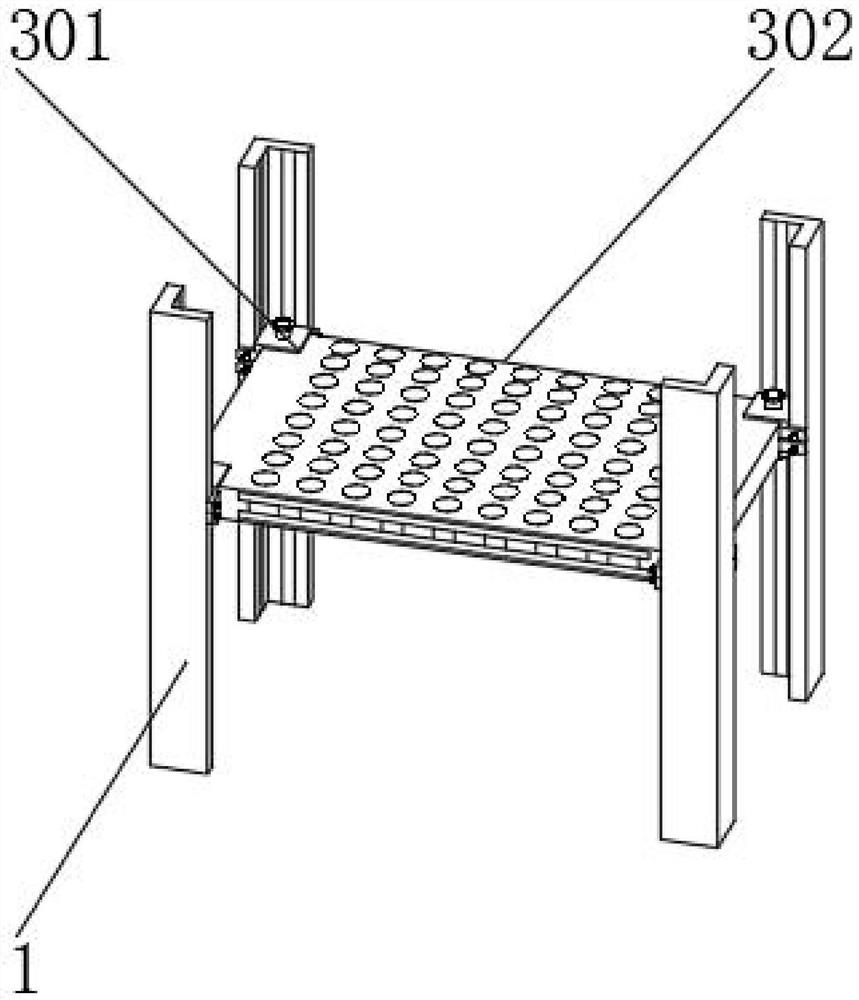

[0049] Such as Figure 1-Figure 8 As shown, a support device for building a steel structure house includes a bracket 1, the inner surface of the bracket 1 is provided with a chute 2, the front surface of the chute 2 is detachably connected with a safety adjustment mechanism 3, and the lower end of the safety adjustment mechanism 3 can be There is a multi-functional support mechanism 4 for detachment connection, and a fixing mechanism 5 is detachably connected to the outer surface of one end of the support 1. The fixing mechanism 5 includes a fixing plate 501, an L-shaped hollow box 502, a fixing component 503, a fixing pile 504, a hollow ring 505 and Secondary fixing clamping plate 506 .

[0050] The working principle of the above-mentioned technical scheme is as follows:

[0051] By placing the bracket 1 at the designated position, and then sliding the No. 1 special-shaped clamping plate 301 and the No. 2 special-shaped clamping plate 303 through the chute 2, the No. 1 speci...

Embodiment 2

[0054] The provided fixing mechanism 5 is conducive to improving the fixing effect of the overall structure, avoiding device shaking, reducing risks, and ensuring the safety of construction personnel.

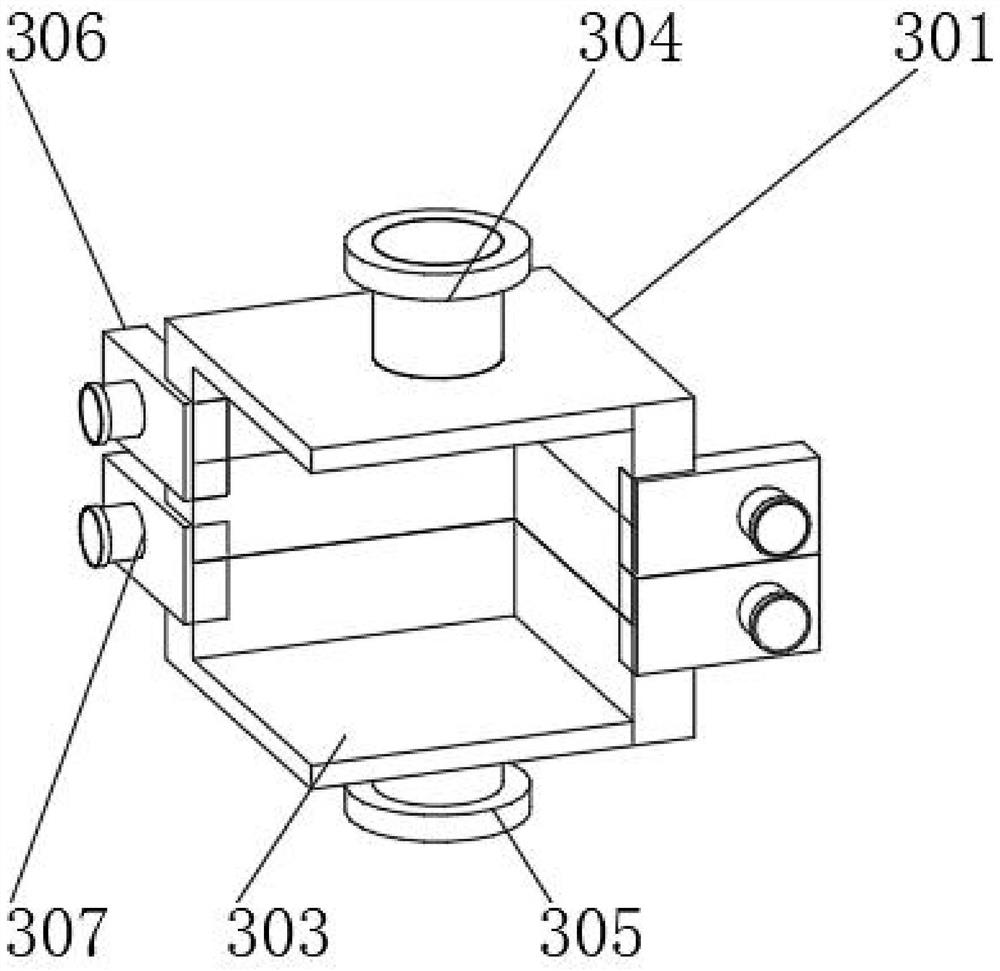

[0055] In another embodiment, such as Figure 8 As shown, the outer surface of the upper end of the fixing plate 501 is welded to the outer surface of the lower end of the L-shaped hollow box 502, and the fixing assembly 503 is detachably fixed in the middle of the front end of the L-shaped hollow box 502 through a bolt hole. The number of the fixing assemblies 503 is two groups , the fixing component 503 includes a bolt rod and a bolt cap.

[0056] By inserting the bracket 1 into the L-shaped hollow box 502, and then fixing the bracket 1 through the fixing component 503, the installation is quick and easy, and then the fixing pile 504 is inserted into the ground, and the fixing plate 501 is closely attached to the ground to prevent the bracket 1 from tilting.

[0057] In anot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com