Thermal management device and valve module

A valve module and valve body technology, applied in valve devices, multi-port valves, engine components, etc., can solve the problems of complex installation, many connections in the thermal management system, and large space occupation, so as to reduce pipeline connections and simplify thermal management. effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

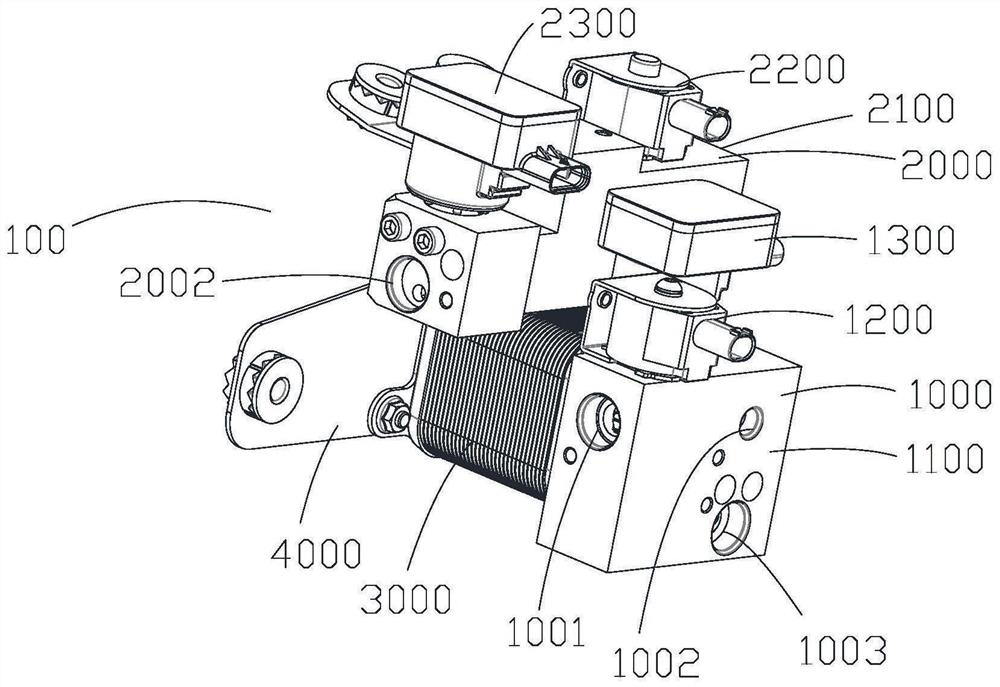

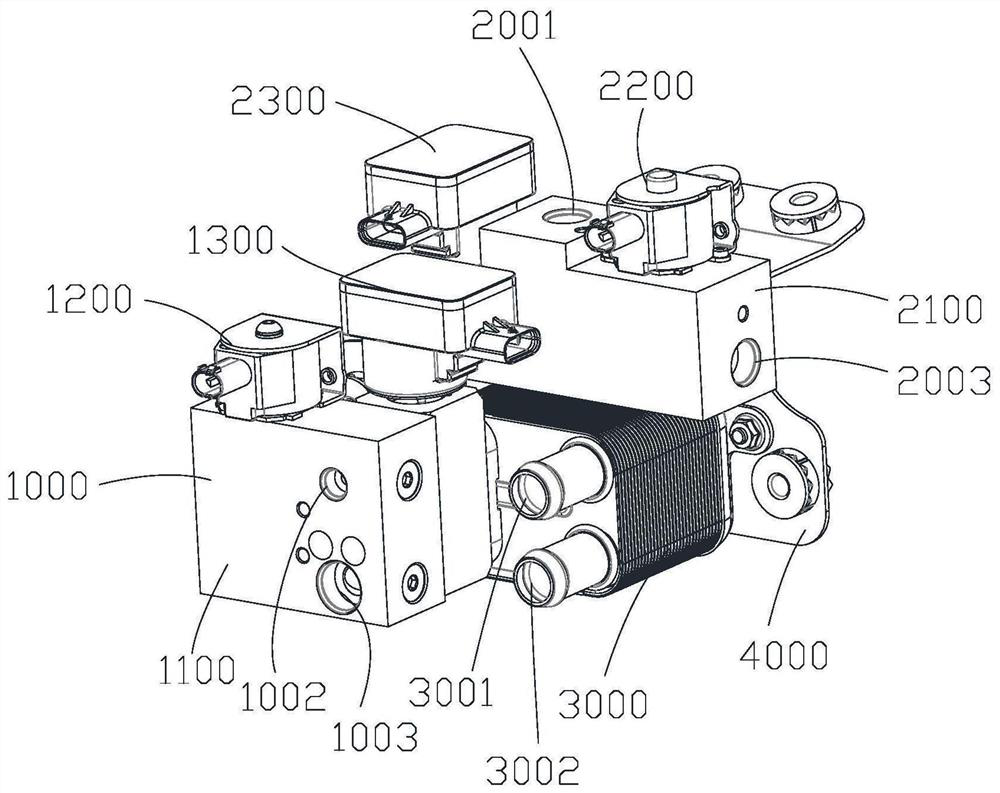

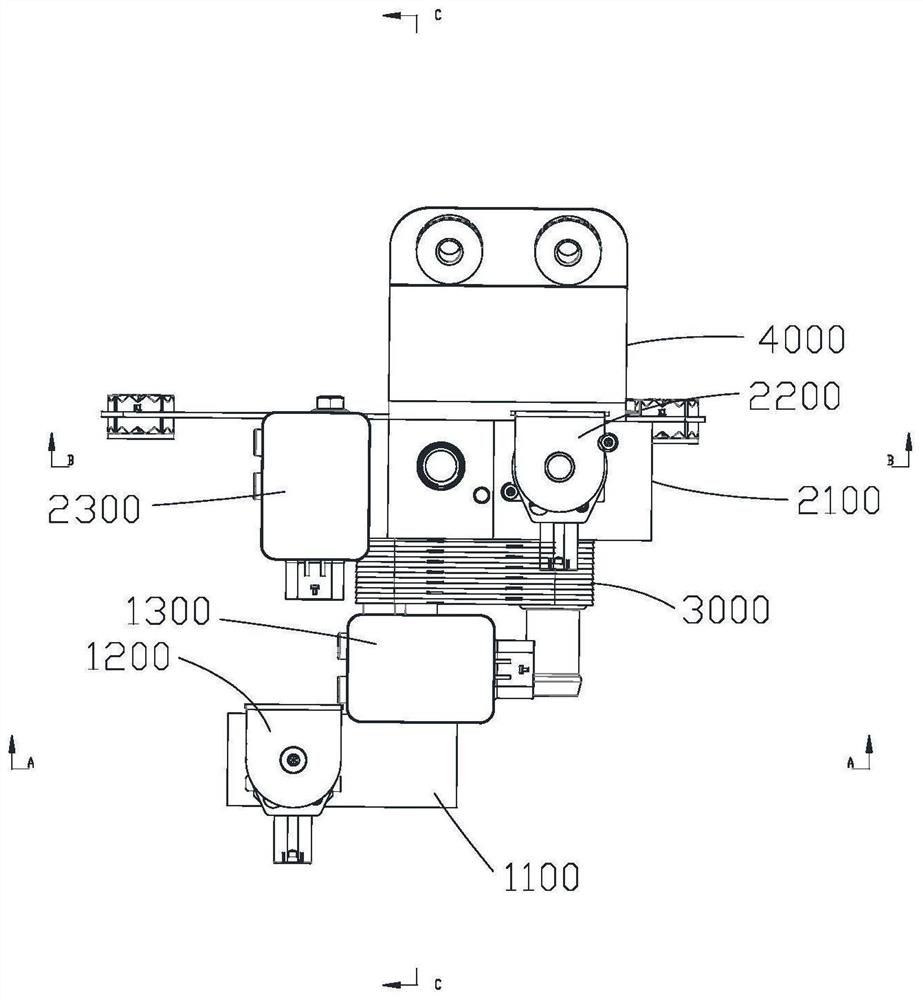

[0027] see Figure 1-Figure 12 . The heat management device 100 includes a bracket 4000, a valve module and a heat exchange core 3000, and the valve module is fixedly connected or limitedly connected with the heat exchange core. In this embodiment, the valve module includes a first valve module 1000 and a second valve module 2000, wherein the first valve module 1000 is fixed to the heat exchange core 3000, and the first valve module 1000 has a channel communicating with the heat exchange core 3000 , the refrigerant in the first valve module 1000 can flow into the heat exchange core, the bracket 4000 is fixed to the heat exchange core 3000, the second valve module 2000 is fixed to the bracket 4000, and the fixing method of the above-mentioned structural parts of the thermal management device 100 can be Welding or screw fixing or other fixing methods.

[0028] The first valve module 1000 has a first interface 1001, a second interface 1002, and a third interface 1003, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com