Intensive integrated water purification equipment

An intensive, water purification equipment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as complex connection, achieve compact connection and reduce floor space , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

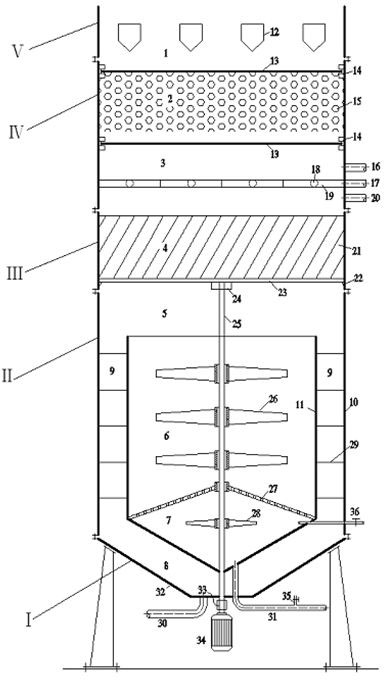

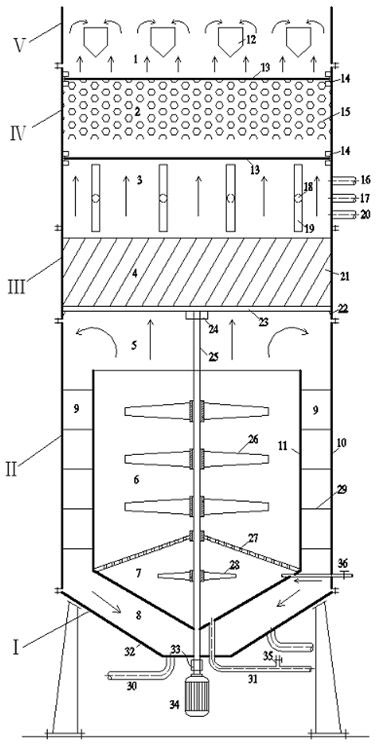

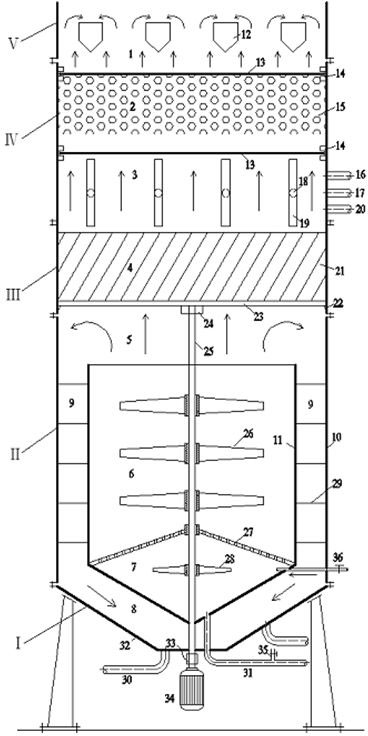

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

[0034] The design concept of the intensive integrated water purification equipment of the present invention is to design a mobile integrated water purification equipment with small footprint, high water purification efficiency, compact connection of each water purification unit, and convenient assembly. Combining mixing, agglomeration and flocculation, shallow sedimentation theory, uniform water distribution theory and upflow filter material backwashing technology, etc., it integrates coagulation, flocculation, clarification, sedimentation, filtration, filter material air-water backwashing and sludge discharge The slag is concentrated in one body. Through the addition of coagulants and the shearing action of small stirring paddles, the particles in the water can be quickly aggregated to form stable microflocs. After the water is evenly distributed by the inverted cone w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com