Combustion chamber capable of automatically adjusting mixed intake air

An automatic adjustment, combustion chamber technology, applied in the field of aero-engines, can solve the problems of turbine blade design difficulty, hot spot temperature surge at the combustion chamber outlet, etc., to improve the total pressure recovery coefficient and combustion efficiency, reduce the inlet Mach number, and reduce the total pressure. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

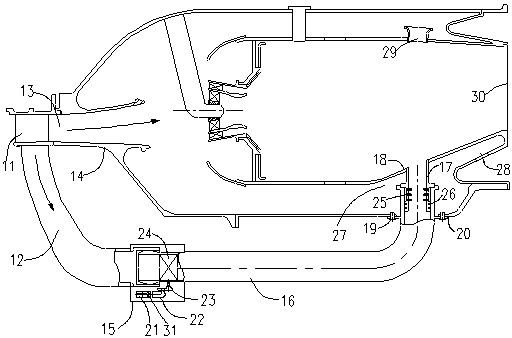

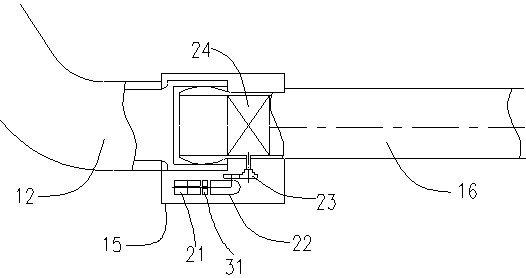

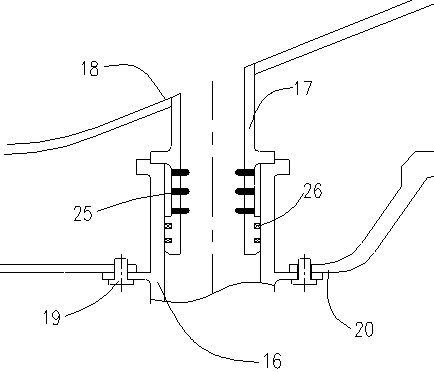

[0025] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a combustor capable of automatically adjusting the mixed intake air, connected to the last stage guide vane 11 of the compressor, and the combustor capable of automatically adjusting the mixed intake air includes a flame tube 18, a diffuser 14 and blending intake components. The structure and positional relationship between the flame tube 18 and the diffuser 14 is the same as that of the prior art, wherein the diffuser 14 is arranged downstream of the last stage guide vane 11 of the compressor; 11 communicates, the outlet end of the mixed intake component communicates with the flame tube 18, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com