Drying device and process for textile yarn after dyeing

A textile yarn and post-drying technology, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of bulky equipment and high cost, and achieve the effect of uniform ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

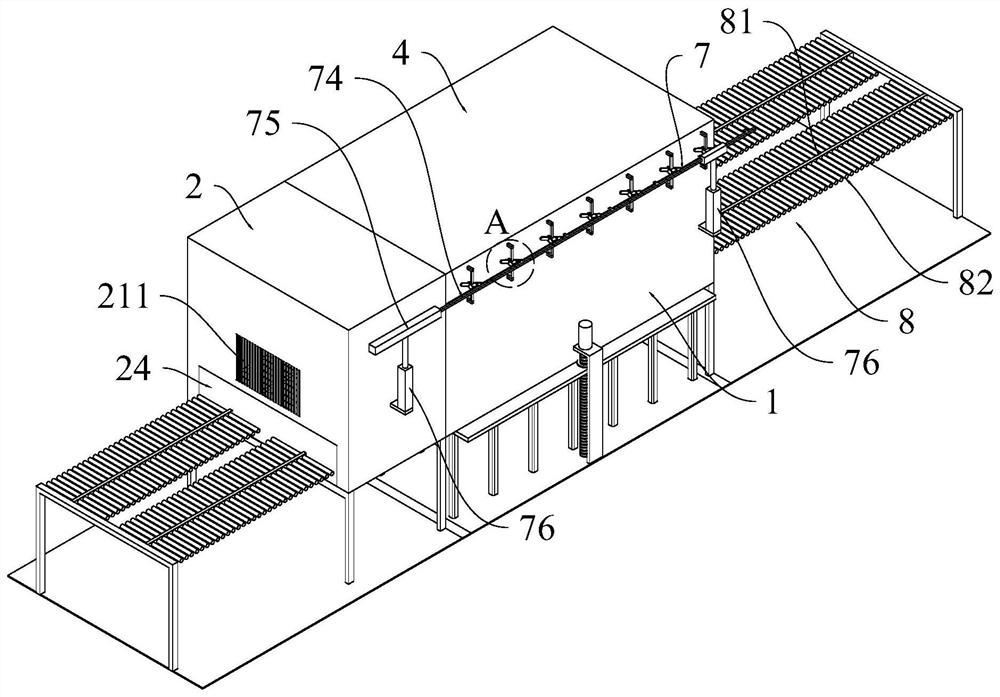

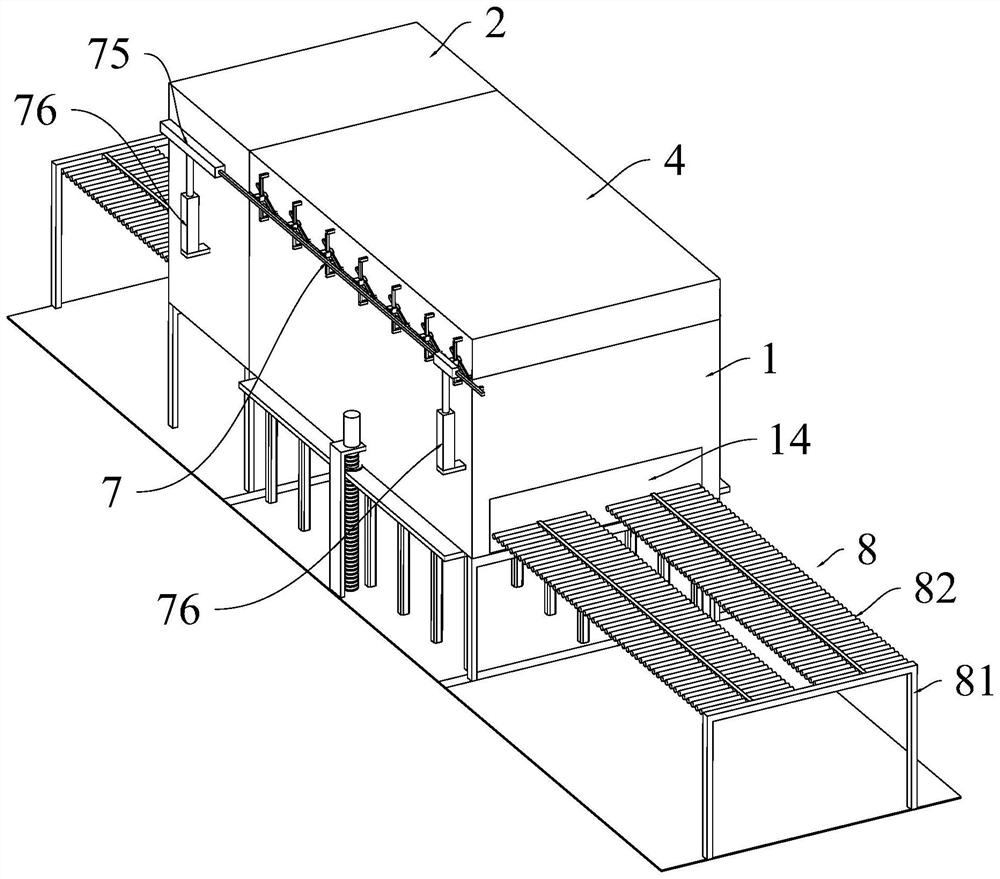

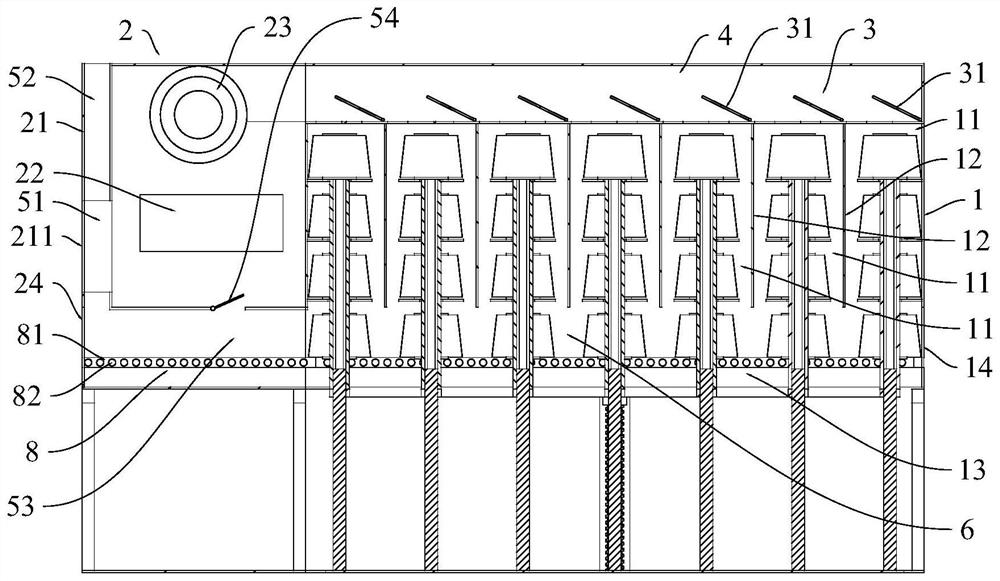

[0032] as attached figure 1 with attached figure 2 The shown drying device for textile yarn after dyeing (hereinafter referred to as "drying device") includes a drying box 1 and a heating device 2; the heating device 2 is used to inject heat into the drying box 1 air flow; if attached image 3 As shown, the inside of the drying box 1 is divided into a plurality of cavities 11 for placing textile yarns by a plurality of partitions 12; The hot air flow is evenly distributed to the air distribution device 3 of each cavity 11 ; the drying device also includes a transport line 4 for inputting and transporting textile yarns into and out of the drying box 1 .

[0033] Further, as attached image 3 As shown, the top of the drying box 1 is provided with an air inlet duct 4, as attached Figure 4 As shown, the lower side of the air inlet duct 4 has a dense array of holes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com