Quantum dot ink, quantum dot film and light-emitting device

A technology of light-emitting devices and quantum dots, which is applied in the field of light-emitting and display, can solve the problems of easy phase separation and unfavorable printing, and achieve the effect of suppressing quenching and increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Another embodiment of the present invention also provides the preparation method of above-mentioned quantum dot ink, comprises the following steps:

[0058] According to the above-mentioned components and proportions of the quantum dot ink, disperse the luminous quantum dots and spacer quantum dots in an organic solvent and mix them uniformly to prepare the quantum dot ink.

[0059] In some of the embodiments, the stirring time for uniform mixing is 5 minutes to 60 minutes.

[0060] An embodiment of the present invention also provides a quantum dot thin film, including luminescent quantum dots and spaced quantum dots. Wherein, the luminescent quantum dot includes a first quantum dot core and a first shell layer covering the first quantum dot core.

[0061] The luminescent quantum dot includes a first quantum dot core and a first shell layer covering the first quantum dot core, and the first shell layer is a II-VI group material.

[0062] Spaced quantum dots, comprisin...

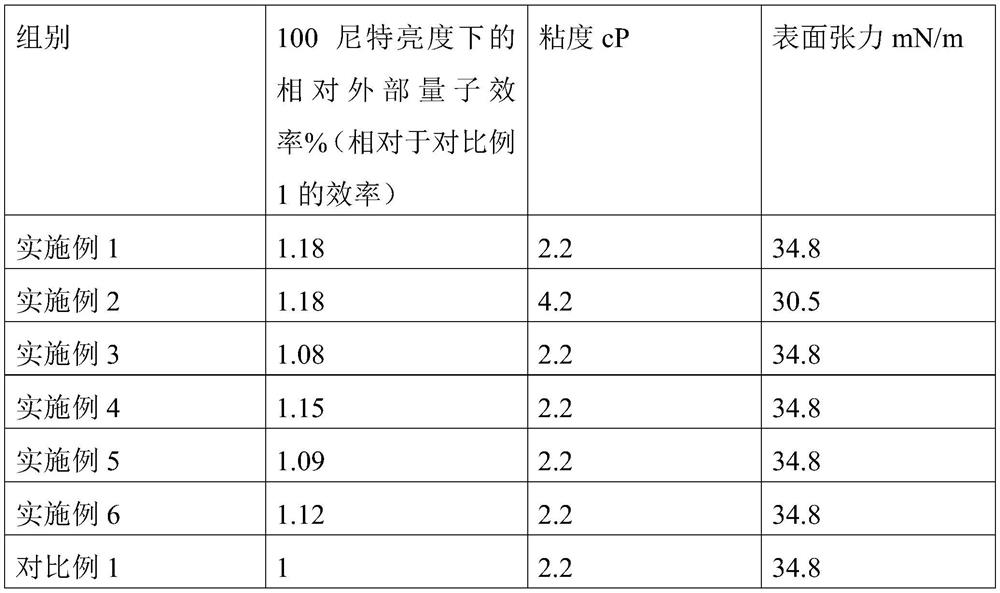

Embodiment 1

[0076] Quantum dot inks include organic solvents, luminescent quantum dots and spacer quantum dots.

[0077] Among them, the organic solvent is tetralin, the luminescent quantum dot is CdSe(5nm) / ZnS(8nm), and the spacer quantum dot is CdSe(5nm) / ZnS(8nm) / SiO 2 (5nm). In the quantum dot ink, the mass percentage of tetralin is 95%, the mass percentage of luminescent quantum dots is 2.5%, and the mass percentage of spacer quantum dots is 2.5%.

[0078] The preparation process of the above-mentioned quantum dot ink is as follows: add the following components to a 500mL single-necked flask, and the order of addition is: 5g luminescent quantum dots, 5g spacer quantum dots, 190g tetralin solvent, fully shake and stir for 60 minutes to obtain 200g quantum dots ink.

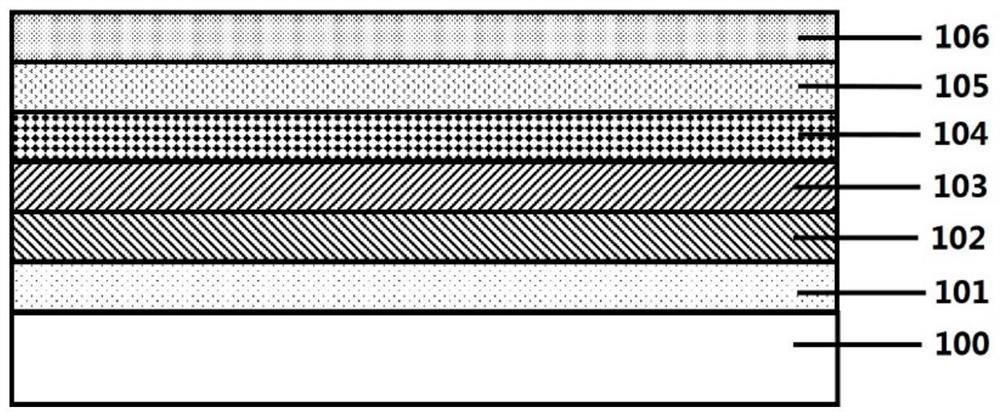

[0079] The structure of the quantum dot electroluminescent device includes a substrate 100 , an anode layer 101 , a hole injection layer 102 , a hole transport layer 103 , a light emitting layer 104 , an electron transpo...

Embodiment 2

[0087] Quantum dot inks include organic solvents, luminescent quantum dots and spacer quantum dots.

[0088] Among them, the organic solvent is a binary mixed solvent composed of methyl nonanoate and dicyclohexyl; the luminescent quantum dots are CdSe(5nm) / ZnS(5nm), and the spacer quantum dots are CdSe(5nm) / ZnS(5nm) / SiO 2 (8nm). In the quantum dot ink, the mass percentage of methyl nonanoate is 50%, the mass percentage of dicyclohexyl is 46%, the mass percentage of luminescent quantum dots is 1.6%, and the mass percentage of spacer quantum dots is 2.4%.

[0089] The preparation process of quantum dot ink includes: adding the following components into a 500mL single-necked flask, the addition order is: 3.2g luminescent quantum dots, 4.8g spacer quantum dots, 100g methyl nonanoate solvent, 92g dicyclohexyl solvent, fully Shake and stir for 60 minutes to obtain 200 g of quantum dot ink.

[0090] The structure of the quantum dot electroluminescent device is similar to that of Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap