Contact module for plug assembly

A technology for plug assemblies and contact modules, which is applied to contact parts, electrical components, parts of connecting devices, etc., can solve problems such as expensive manufacturing of electroplated plastic shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

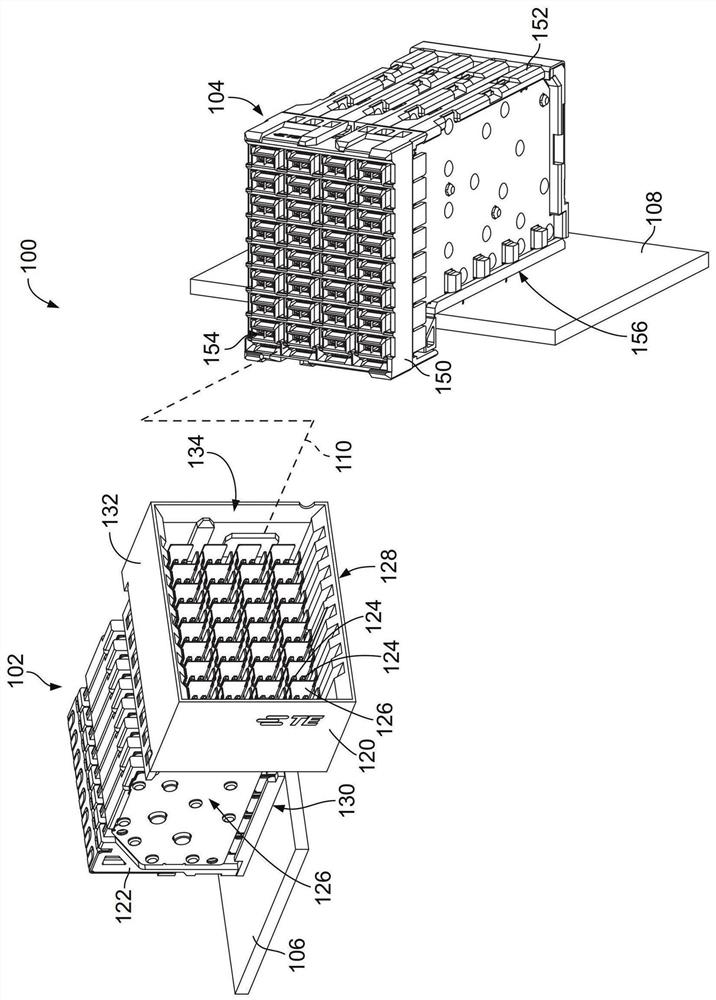

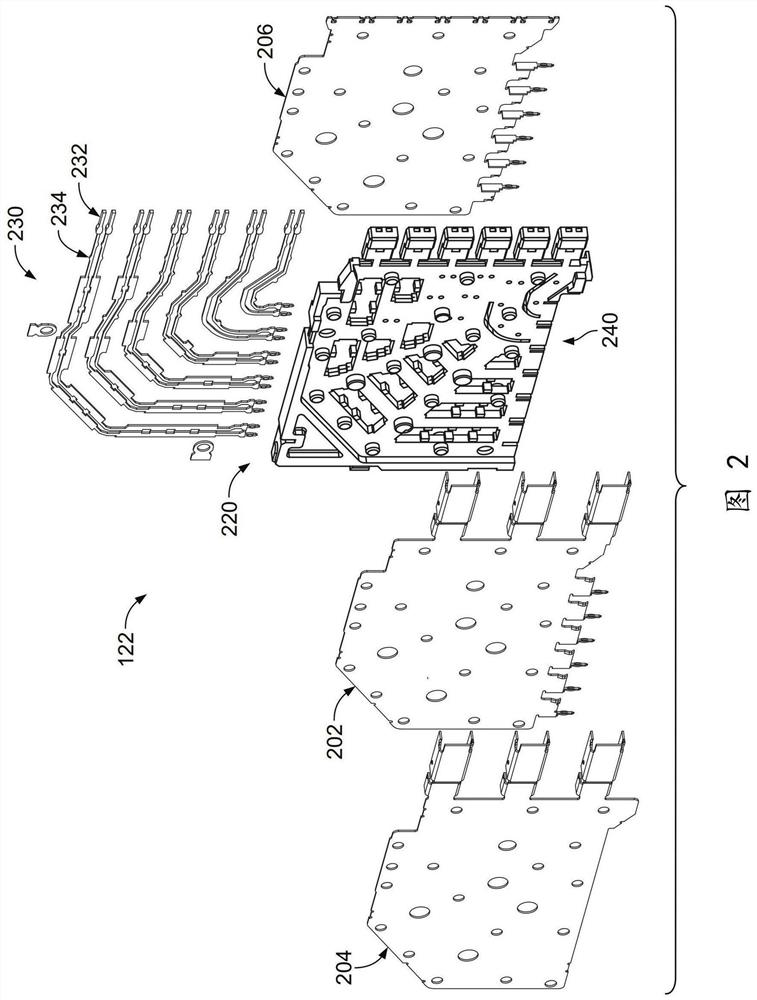

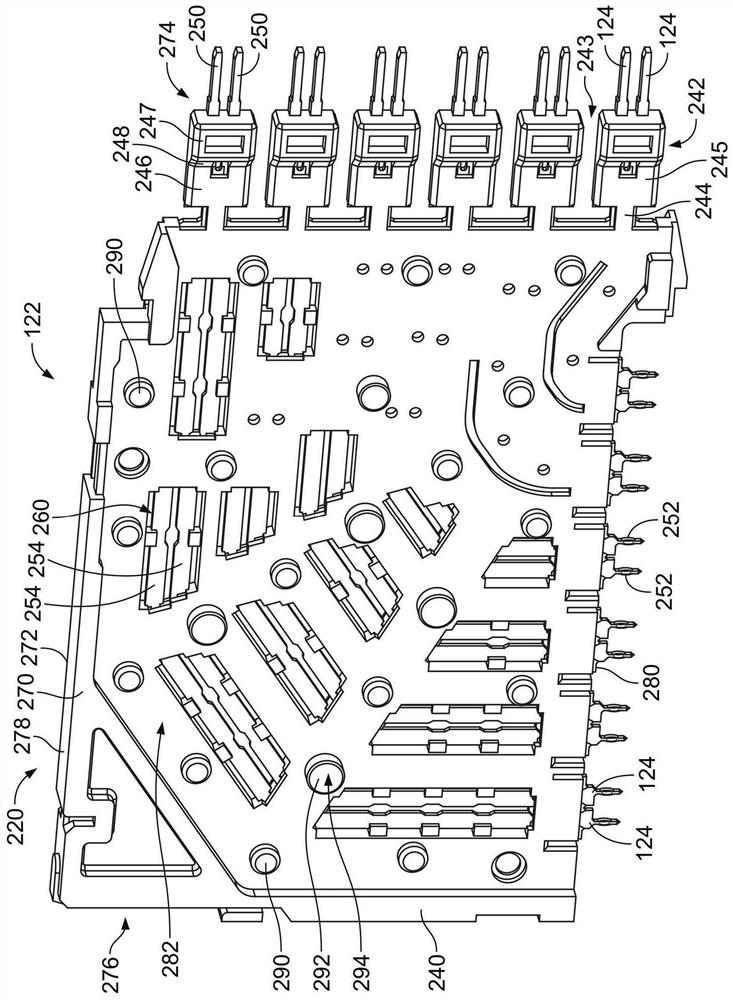

[0026] figure 1 is a perspective view of an exemplary embodiment of an electrical connector system 100 showing a first connector assembly 102 and a second connector assembly 104 that may be mated directly together. The first connector assembly 102 and / or the second connector assembly 104 may be referred to hereinafter individually as a "connector assembly" or collectively as a "connector assembly(s)". The first connector assembly 102 or the second connector assembly 104 may be a receptacle assembly, and the first connector assembly 102 or the second connector assembly 104 may be a plug assembly. In the description, first connector assembly 102 and corresponding components may be referred to as header assembly 102 and corresponding header components, and second connector assembly 104 and corresponding components may be referred to as receptacle assembly 104 and corresponding receptacle components.

[0027] The first and second connector assemblies 102 , 104 are each electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com