Initial position detection of electric motor

An initial position detection and motor technology, applied in the field of motors, can solve the problems of reducing the reliability of rotor position detection, increasing the start-up time of the motor, and estimating the accuracy of the rotor position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

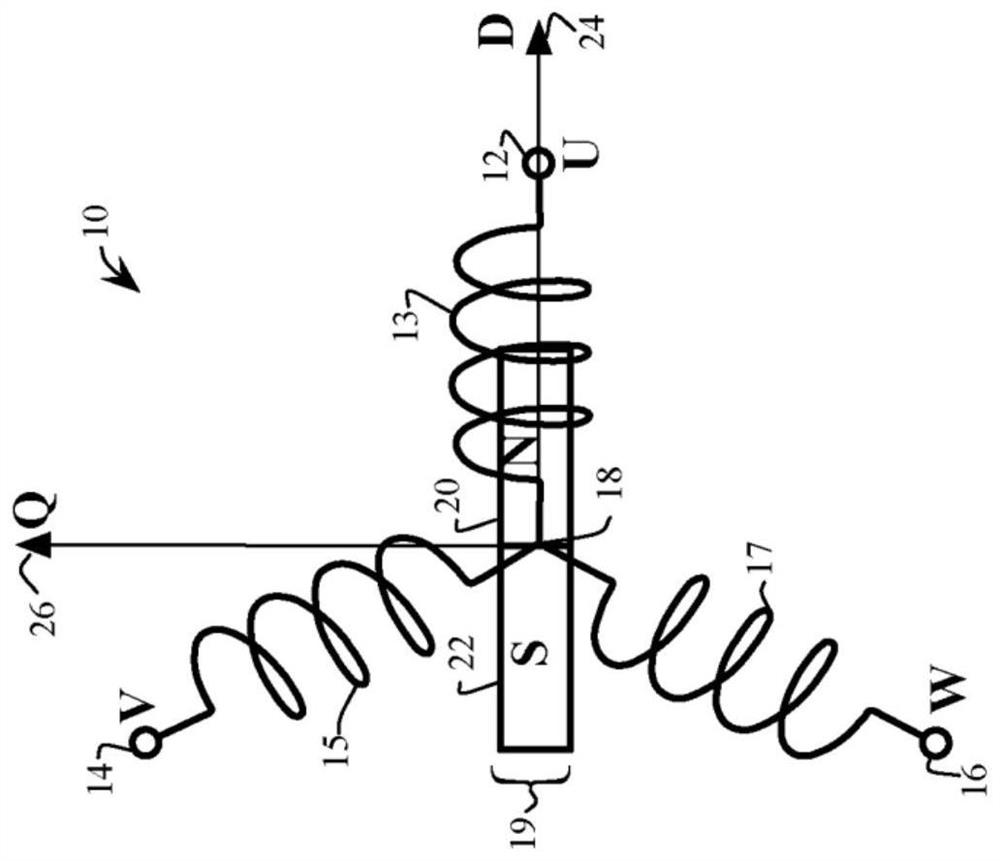

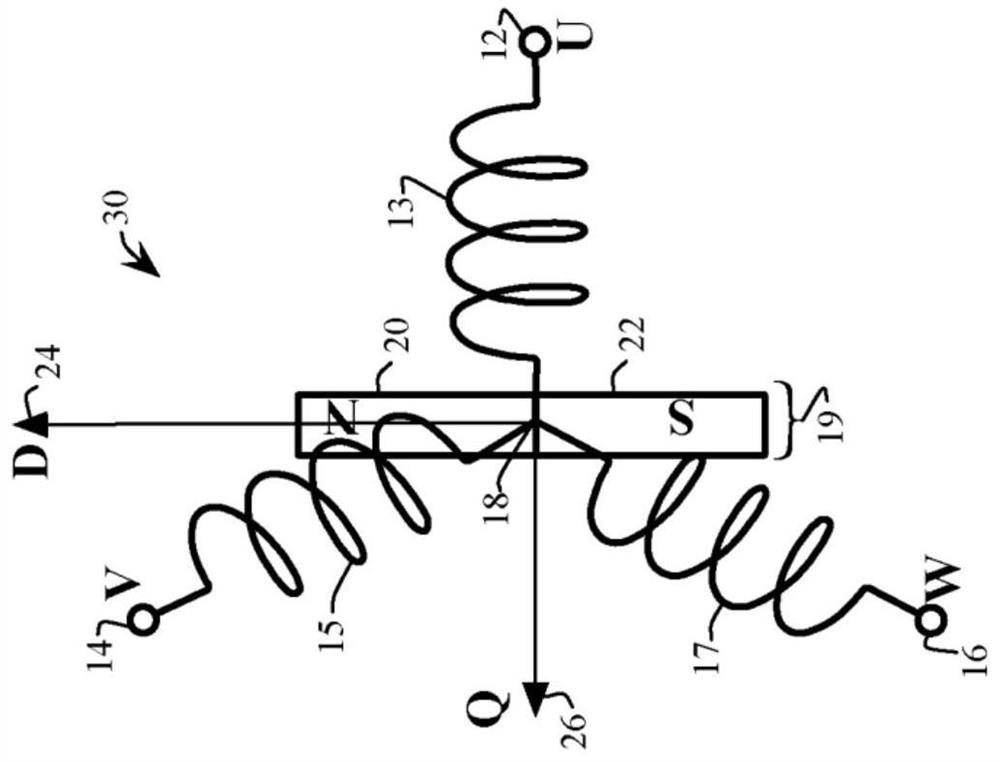

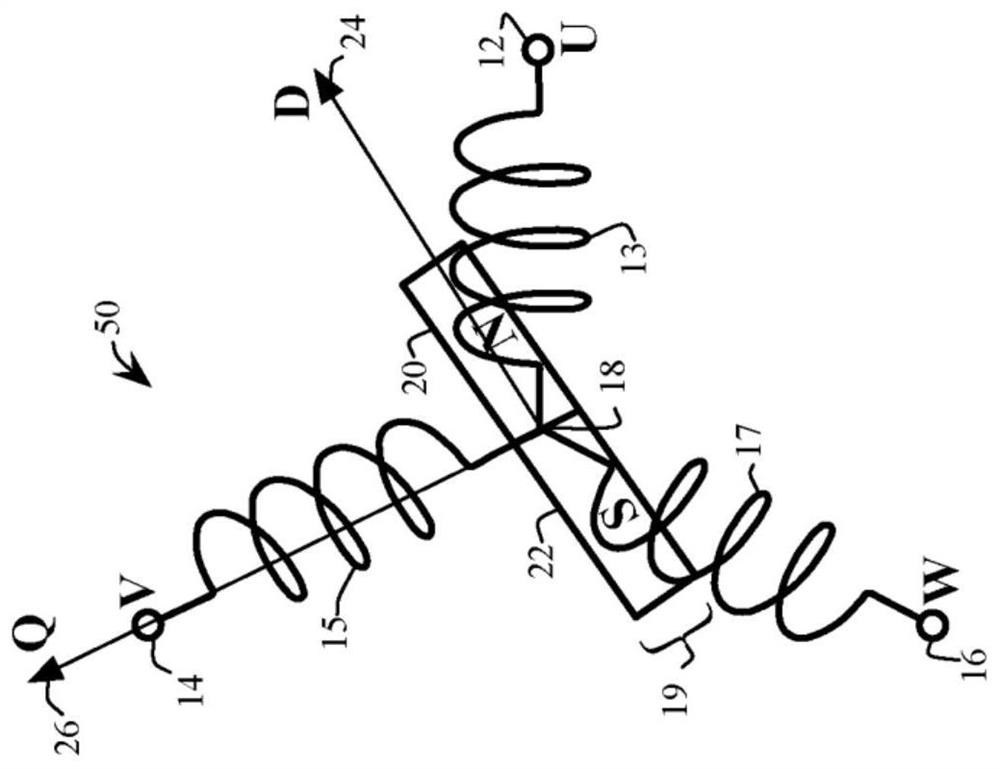

[0058] Embodiments described herein provide detection of rotor position and polarity to facilitate starting of the motor. Three short pulses are injected sequentially in each pair of the three stator windings, with measurements taken during the pulse injection interval and during the 'freewheel' interval. The freewheeling interval occurs when the injected voltage pulse is removed and the stator develops a back electromotive force (EMF) as the stator inductor is de-energized. Relative voltage measurements were made for each pair of stator windings by subtracting the freewheeling voltage from the injected voltage during pulse injection. In one embodiment, the center tap voltage is determined by measuring the voltage difference of each pair of inductors with a floating phase (eg, the remaining inductor that does not form the inductor pair). The value of the center tap voltage is related to the ability of the stator inductor to generate and release magnetic field energy, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com