Inlet cone for an aircraft turbine engine and associated aircraft turbine engine

A turbine engine and aircraft technology, applied in the field of gas turbine engines and turbine engines, can solve problems such as insufficient separation, and achieve the effects of simple design, reduced size, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

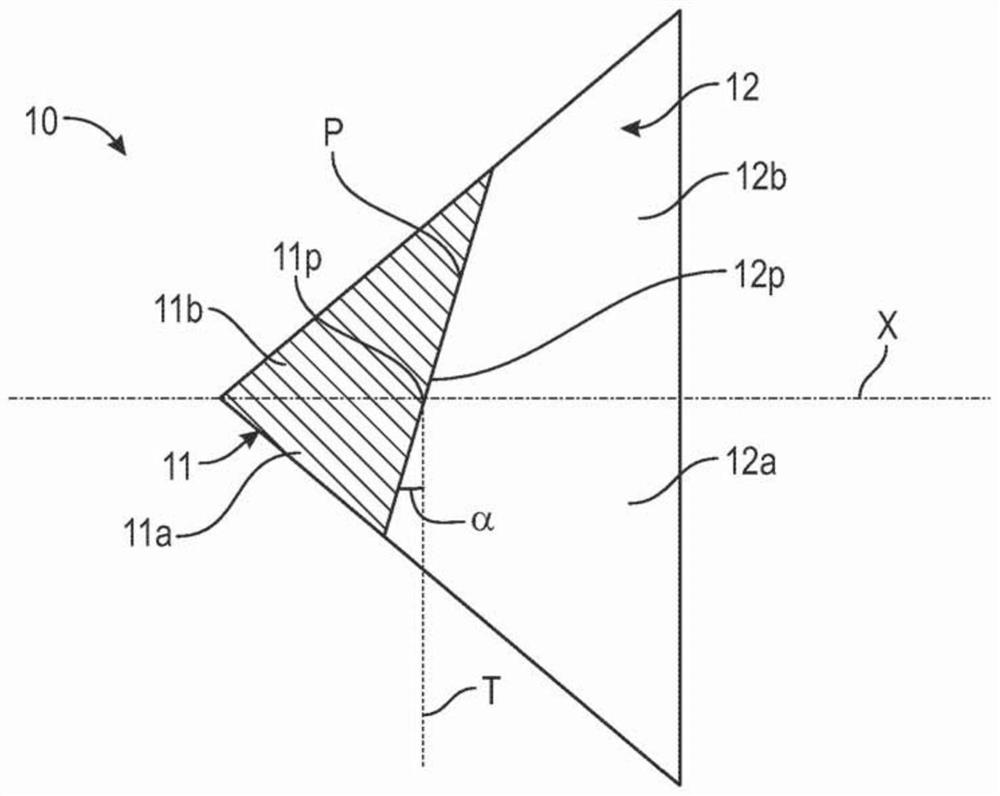

[0030] As is customary in this application, the terms "inner" and "outer" and "inner" and "outer" are defined radially with respect to the longitudinal axis X of the aircraft engine of the turbine engine. Thus, a cylinder extending along the axis X of the engine comprises an inner surface facing the shaft of the engine and an outer surface opposite its inner surface. "Axial" or "axially" means any direction parallel to the axis X, and "transversely" or "transversely" means any direction perpendicular to the axis X. Similarly, the terms "upstream" and "downstream" are defined relative to the direction of airflow in the turbine engine.

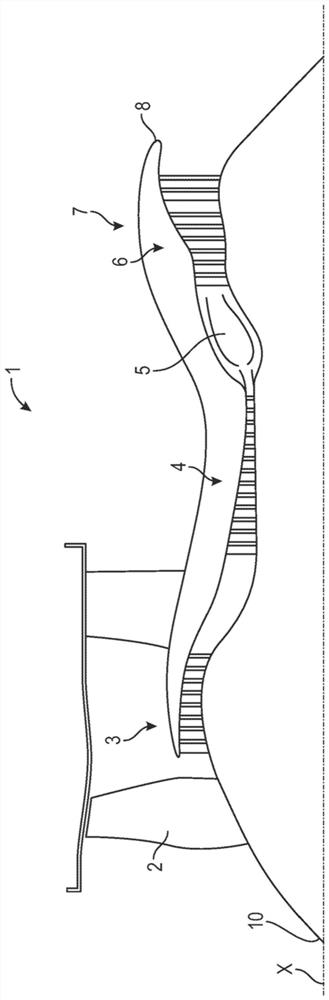

[0031] figure 1 A twin-flow turbine engine 1 is shown. However, this is not limiting and the turbine engine may be another type of turbine engine, eg a turboprop.

[0032] The turbine engine 1 extends along a longitudinal axis X and comprises, from upstream to downstream in the direction of air flow, a fan 2, one or more compressor stages (e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com