Rice water direct seeding fertilization mechanism

A technology for rice and seeding pipes, which is applied to fertilization devices, planter parts, seeding and other directions, can solve the problems of poor uniformity of swayed fertilizers, low operation efficiency, and high labor intensity of artificial fertilization, so as to improve the utilization rate of fertilizers and improve the operation efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

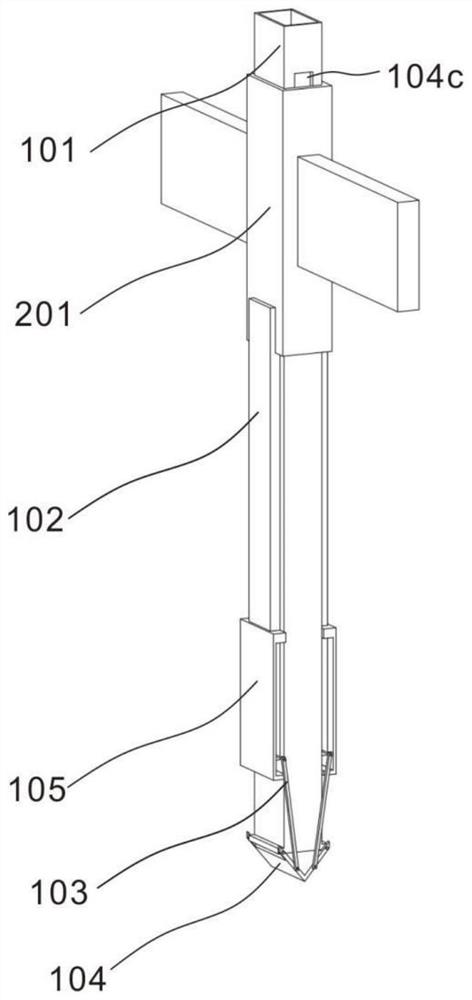

Embodiment 1

[0033] refer to Figure 1~3 , which is the first embodiment of the present invention, this embodiment provides a rice water direct seeding fertilization mechanism, including a direct seeding assembly 100 and a fertilization assembly 200, and the direct seeding assembly 100 includes a seeding pipe 101, a connecting plate 102, a pole 103 and a movable plate 104, the inside of the sowing tube 101 is hollow, and both ends communicate with the outside world. The rice seeds can enter the sowing tube 101 from the top of the sowing tube 101 and pass through the sowing tube 101. The bottom of the sowing tube 101 is movably provided with a movable plate 104. The movable plate 104 can be opened or Close the opening at the bottom of the sowing pipe 101. When the movable plate 104 was opened, the rice seeds in the sowing pipe 101 fell into the soil for sowing. When the plate 102 moves along the sowing tube 101 , the movable plate 104 can be pushed open or closed by the support rod 103 .

...

Embodiment 2

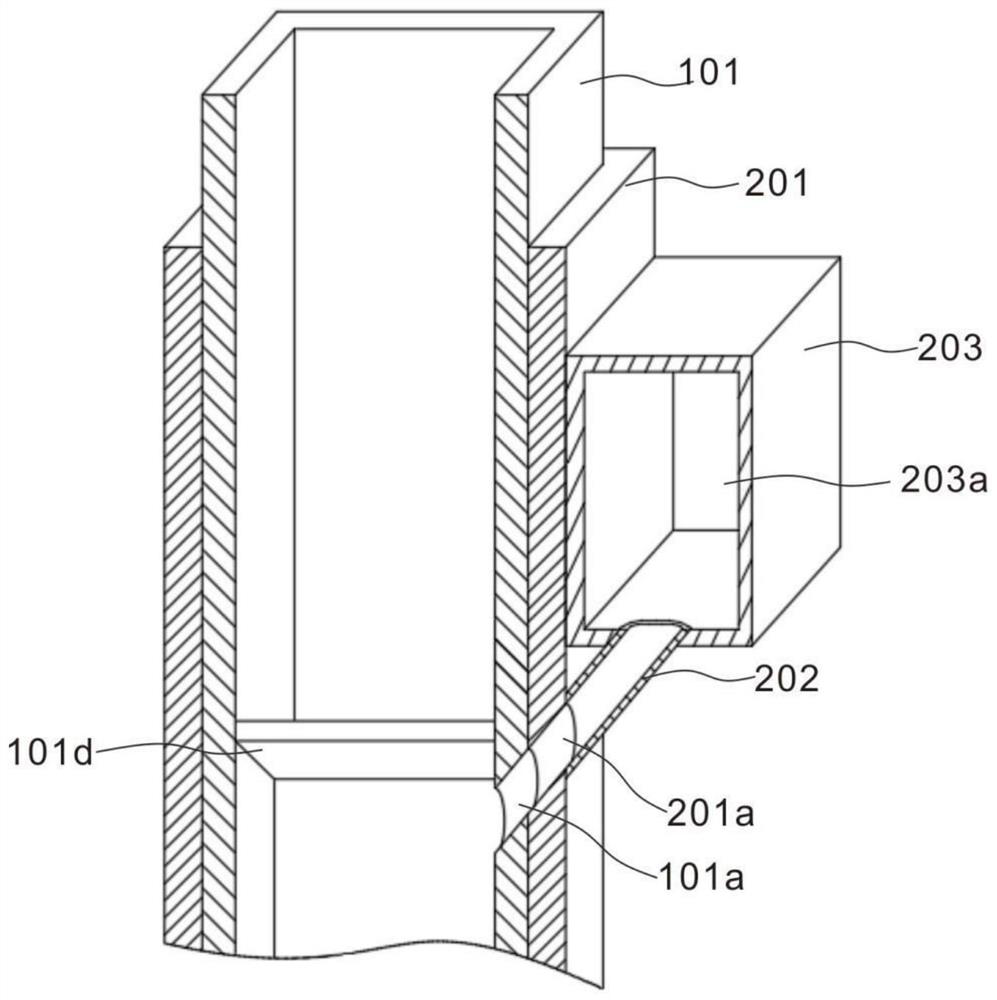

[0036] refer to Figure 3-9 , which is the second embodiment of the present invention. This embodiment is based on the previous embodiment. The broadcast assembly 100 also includes a limiting plate 105. One side of the limiting plate 105 protrudes to form a support block 105a, and the support block 105a is connected to the outer wall of the seeding pipe 101. , the support block 105a is fixedly connected with the outer wall of the sowing tube 101, a limiting groove 105b is formed between the limiting plate 105 and the sowing tube 101, and the inner wall of the limiting groove 105b is slidably provided with a connecting plate 102, and the connecting plate 102 can be positioned in the limiting groove. The inner wall of 105b slides, and when the connecting plate 102 slides along the outer wall of the seeding pipe 101, it is limited by the limiting groove 105b to avoid deviation when the connecting plate 102 slides. A first fixed shaft 102a is formed. The first fixed shaft 102a is ...

Embodiment 3

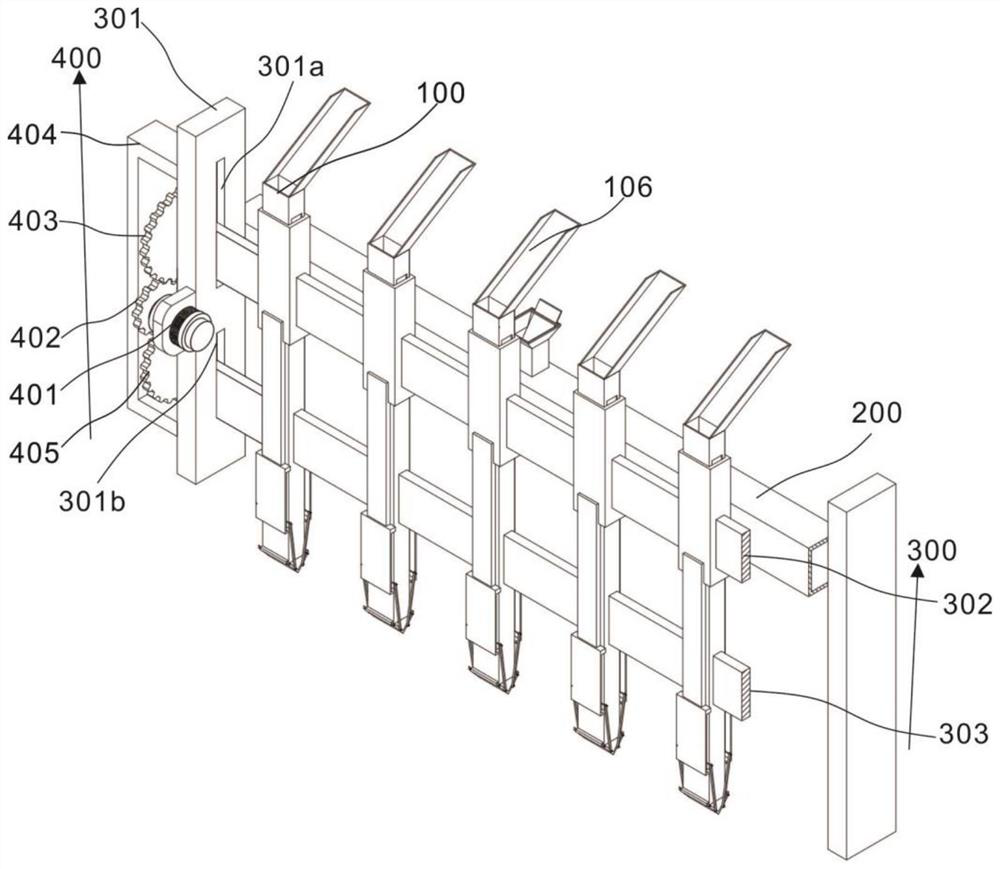

[0047] refer to Figure 1~3 , 9 and 10 are the third embodiment of the present invention. This embodiment is based on the above two embodiments. When the present invention is used, the mounting plate 301 is fixed on the existing sowing trolley, and the guide groove 106 can guide the rice seeds into the sowing tube 101, the driving gear 402 is driven by the motor 401 to rotate, the driving gear 402 can drive the first driven gear 403 and the second driven gear 405, the rotation direction of the first driven gear 403 and the second driven gear 405 Consistent, when the first driven gear 403 and the second driven gear 405 rotate, they can respectively drive the first limit shaft 406 and the second limit shaft 407 around the axis of the first driven gear 403 and the second driven gear 405 respectively. The core rotates, and slides on the inner wall of the first limiting groove 304a and the second limiting groove 305a respectively, which can respectively drive the first limiting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com