Grinding device and grinding method for graphene production and processing

A grinding device and graphene technology, applied in application, cocoa, grain processing and other directions, can solve the problems of low grinding efficiency, long grinding time, and increase the load of grinding mechanism, so as to shorten the grinding time and improve the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

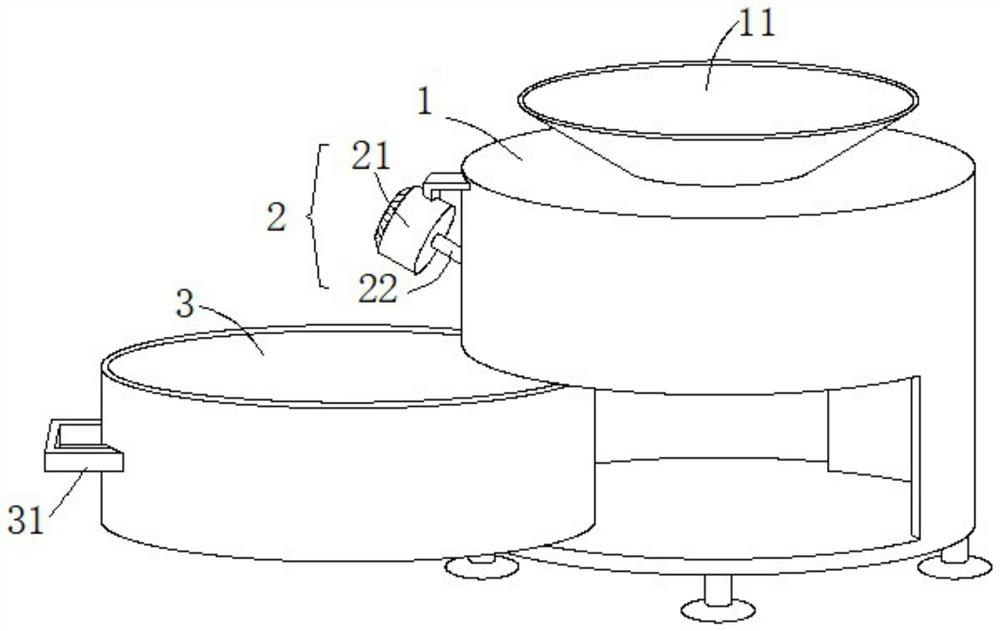

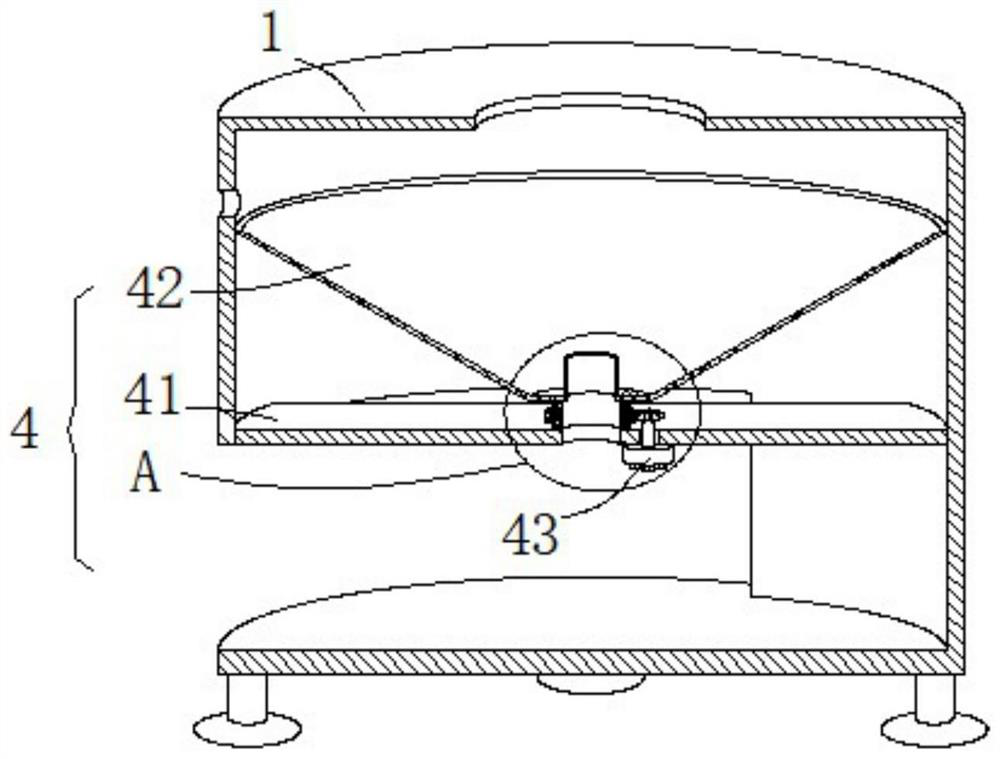

[0029] see Figure 1-3 , the present embodiment provides a grinding device and a grinding method for graphene production and processing, including a grinding cylinder 1, a loading mechanism 4 and a grinding mechanism 2, the loading mechanism 4 is arranged inside the grinding cylinder 1, and the top of the grinding cylinder 1 is opened There is a feed inlet and the opening of the feed inlet is provided with a feed hopper 11, the graphene raw material to be ground is introduced into the inside of the grinding cylinder 1 through the feed hopper 11, and the graphene raw material to be ground is carried by the loading mechanism 4, In order to facilitate the grinding mechanism 2 to quickly and fully grind the graphene raw material in batches, and improve the grinding efficiency.

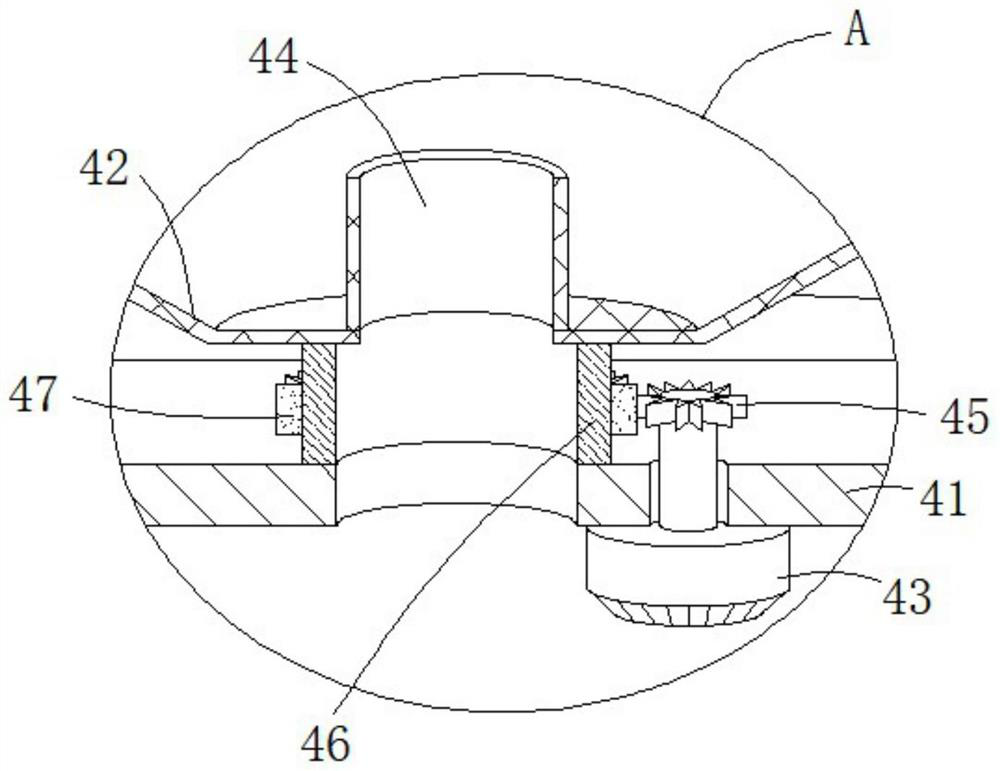

[0030] The loading mechanism 4 includes an inverted truncated cone-shaped loading hopper 42 and a supporting beam 41. The two axial ends of the supporting beam 41 are respectively fixedly connected with th...

Embodiment 2

[0034] see figure 1, image 3 , Figure 4 and Figure 5 , further improvements have been made on the basis of Example 1:

[0035] In order to improve the efficiency of grinding, the loading mechanism 4 also includes a first drive motor 43, the first drive motor 43 is fixedly arranged on the bottom end surface of the support beam 41, and the first drive motor 43 runs through the support beam 41 through the transmission rod and is connected with teeth. The disc 45 and the outer wall of the hollow supporting sleeve 46 are fixedly sleeved with a transmission tooth block 47 meshing with the toothed disc 45, and the first drive motor 43 is used to provide power to drive the toothed disc 45 to rotate. The transmission tooth block 47 meshes, so it can drive the hollow support sleeve 46 and the inverted cone-shaped hopper 42 to rotate synchronously, which helps to feed materials into the grinding seat 23 and improves the grinding efficiency.

[0036] The side wall of the grinding s...

Embodiment 3

[0040] see figure 1 , further improvement is made on the basis of embodiment 2:

[0041] The top edge side wall of the inverted truncated cone type hopper 42 is rotated and attached to the inner radial side wall of the grinding cylinder 1. On the one hand, it can prevent the graphene raw material dropped from the feed hopper 11 from falling from the inverted truncated cone type hopper 42. The top edge falls into the inside of the grinding cylinder 1, and on the other hand, it can prevent the graphene raw material from spilling out from the top edge of the inverted cone-shaped hopper 42 during the grinding process.

[0042] In order to facilitate the concentrated collection of the ground graphene raw material, a pull-out notch is provided on the top of the outer wall of the grinding cylinder 1, and a collection box 3 is slid in the pull-out notch to prevent the ground graphene raw material exported from the feeding hole from spilling everywhere All are, the collection box 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com