Attached type lifting scaffold production equipment

A technology for lifting scaffolding and production equipment, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of inability to ensure the same degree of bending of metal plates and low production efficiency, and achieve verticality and improve efficiency. , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

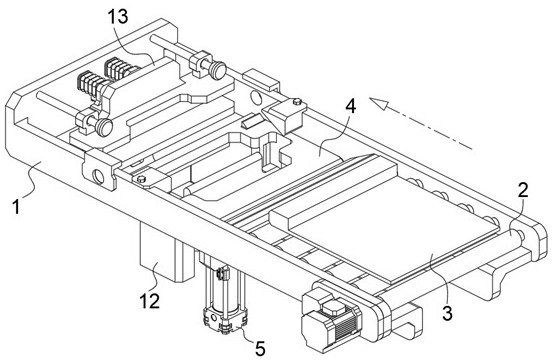

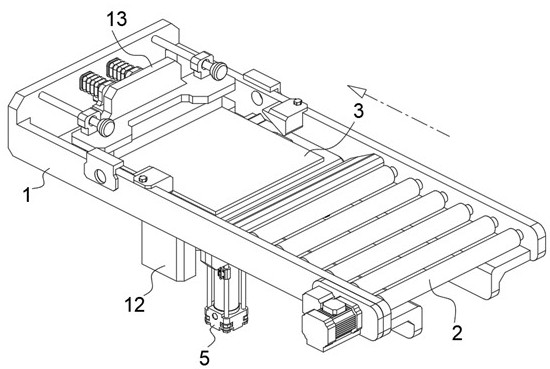

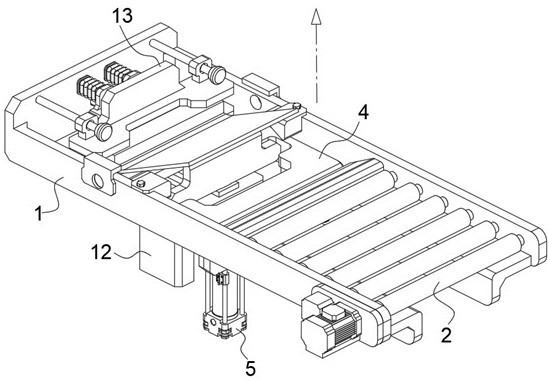

[0036] Embodiment: a production equipment for attached lifting scaffolding, including a frame body 1;

[0037] Conveyor section; the conveyance section includes a conveyor belt 2 arranged on one side of the frame body 1. The conveyor belt 2 is used to convey the bottom plate 3 to be bent. Driven, the conveying part set can convey the metal parts to be bent in time to the bottom plate 3 mentioned above, so as to realize automatic feeding. It is worth noting that during the feeding process of the production equipment , when the bottom plate 3 is placed on the upper side of the conveyor belt 2, the drive motor can make the bottom plate 3 be transported from the right side to the left side, and when it is transported to the left side of the conveyor belt 2, it will bend A fixed plate 11 is provided between the receiving plate 4 at the fold position and the middle part of the conveyor belt 2, the top surface of the fixed plate 11 is provided with an inclined surface 1101, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com