Active fault diagnosis method for space manipulator

A space manipulator and fault diagnosis technology, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as lack of fault tolerance, system damage, and difficulty in modeling accurate models, so as to achieve wide application prospects and realize fault separation , the effect of overcoming modeling difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is exemplary only, and is not intended to limit the scope of the invention and its application.

[0102] Terms involved:

[0103] AFD: Active Fault Diagnosis,

[0104] FTC: Fault-tolerant Control,

[0105] CRL: Constrained Reinforcement Learning,

[0106] MMD: Maximum Mean Discrepancy.

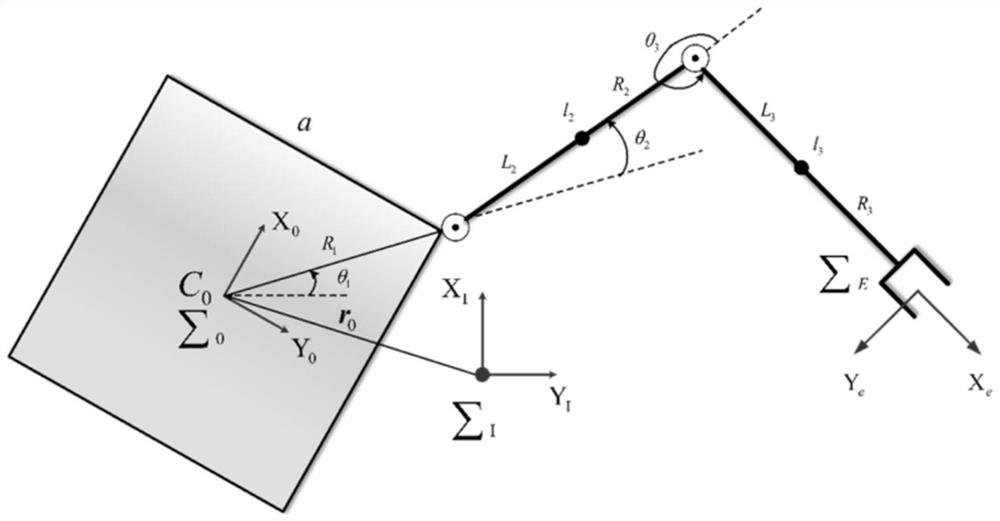

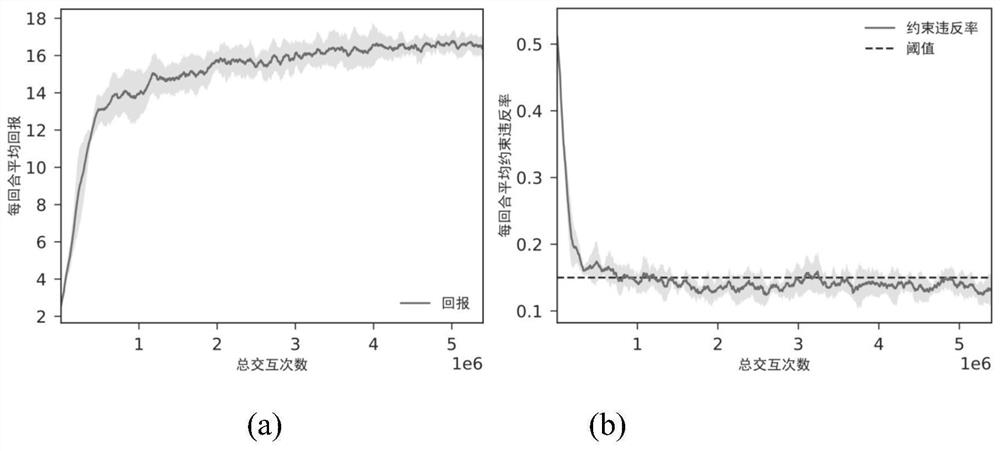

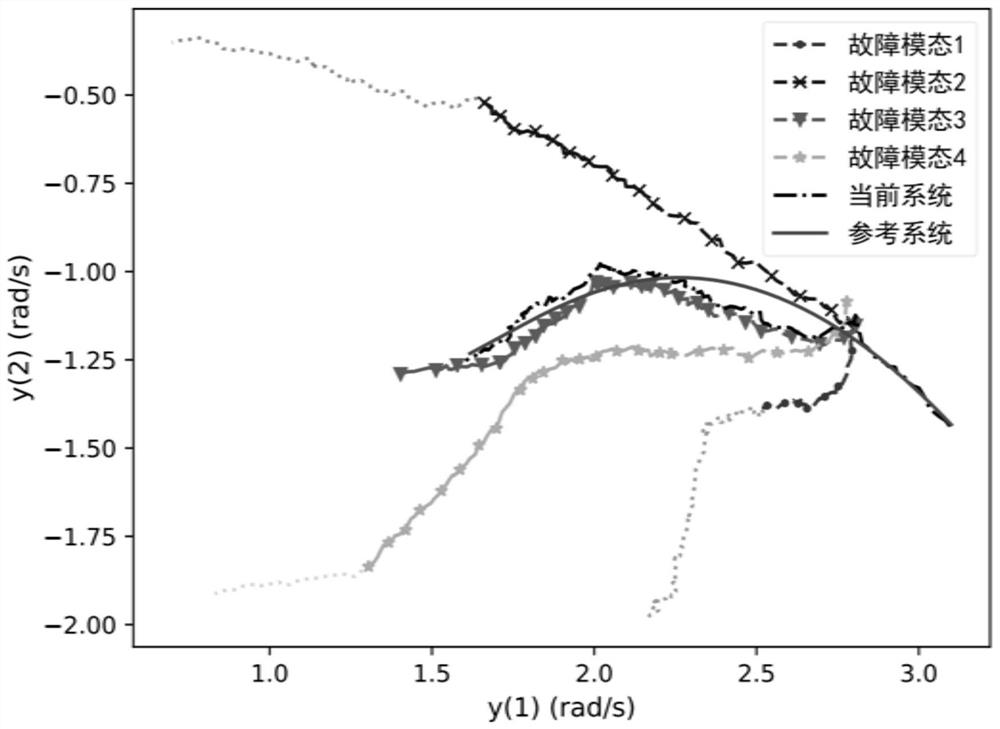

[0107] The embodiment of the present invention provides an active fault diagnosis method for a space manipulator, which constructs an active fault diagnosis framework through active input based on constrained reinforcement learning (CRL) and a fault isolation method based on maximum mean difference (MMD) index; The constrained reinforcement learning algorithm is introduced into the input of the modular space manipulator system, so that the input can maximize the output difference of each fault mode and realize fault separation under the premise of ensuring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com