Double-layer C6v lattice metamaterial sensor based on three-dimensional metal printing technology

A sensor and metamaterial technology, applied in the field of double-layer C6v lattice metamaterial sensor, can solve the problems of machining accuracy error, low signal-to-noise ratio, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0032] The double-layer C6v lattice metamaterial sensor based on three-dimensional metal printing technology provided by this application can be applied to acoustic integrated devices, improving the signal fidelity and signal-to-noise ratio of acoustic integrated devices.

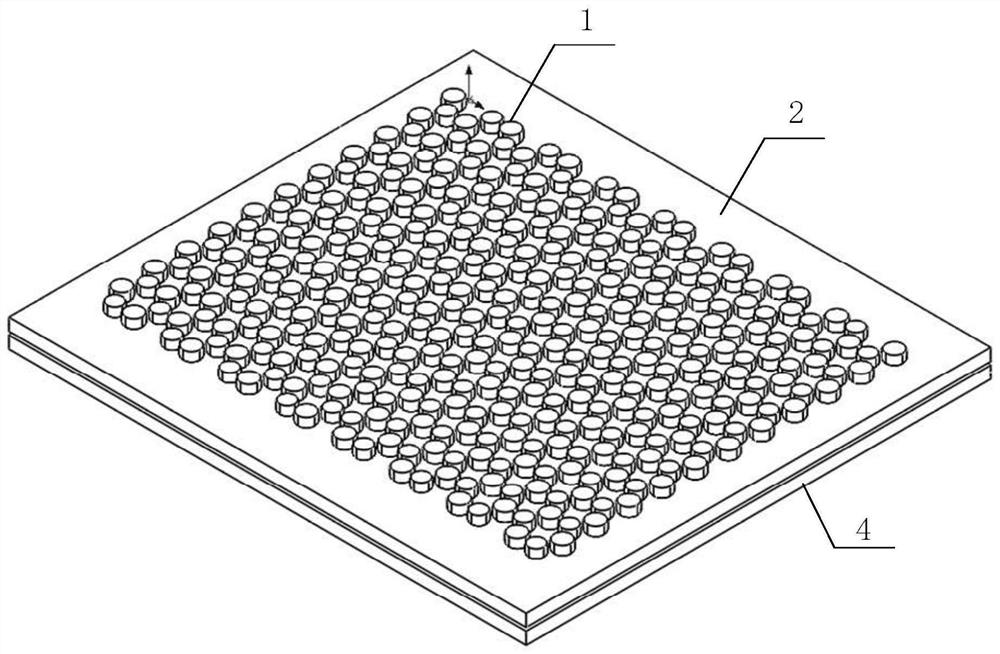

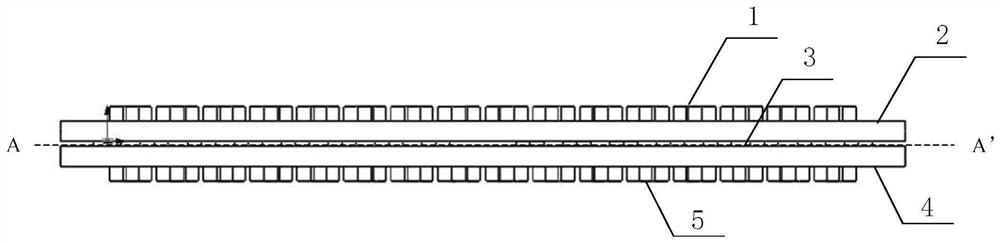

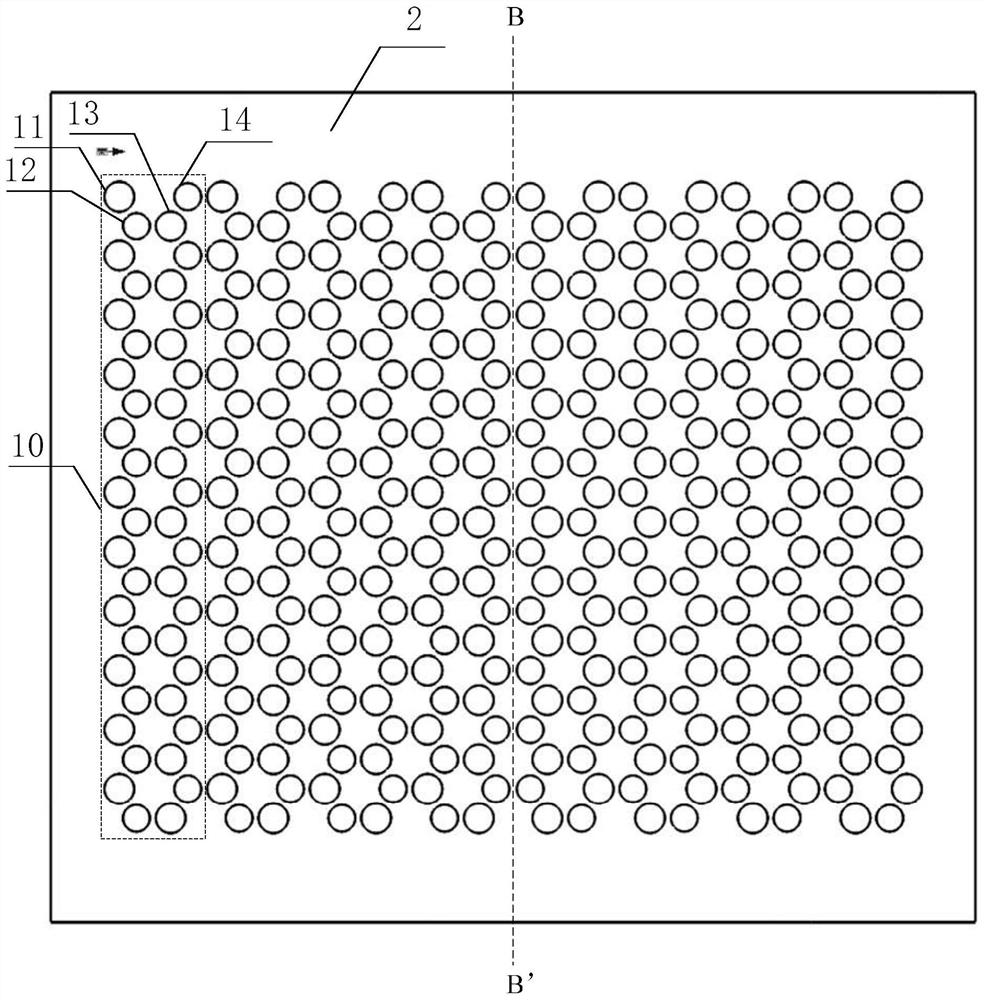

[0033] Such as Figure 1 ~ Figure 2 As shown, the double-layer C6v lattice metamaterial sensor based on three-dimensional metal printing technology provided by the embodiment of the present application includes a first periodic lattice structure 1 integrally formed by three-dimensional metal printing, a first substrate 2, and a second periodic dot A matrix structure 3, a second substrate 4 and a third periodic lattice structure 5, the second periodic lattice structure 3 is arranged between the lower surface of the first substrate 2 and the upper surface of the second substrate 4; The first per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com