Unloading and variable-resistance damping structure for steel wire rope

A steel wire rope and resistance technology, which is applied in the field of structure with variable resistance and shock absorption for moving objects, can solve the problems of elevator falling, hidden dangers of passengers' lives, lack of protection schemes, etc., and achieve high-sensitivity triggering and anti-rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, detailed description will be given below in conjunction with the accompanying drawings and embodiments. It should be understood that the invention examples specifically described here are only used to explain the present invention, but not to limit the present invention.

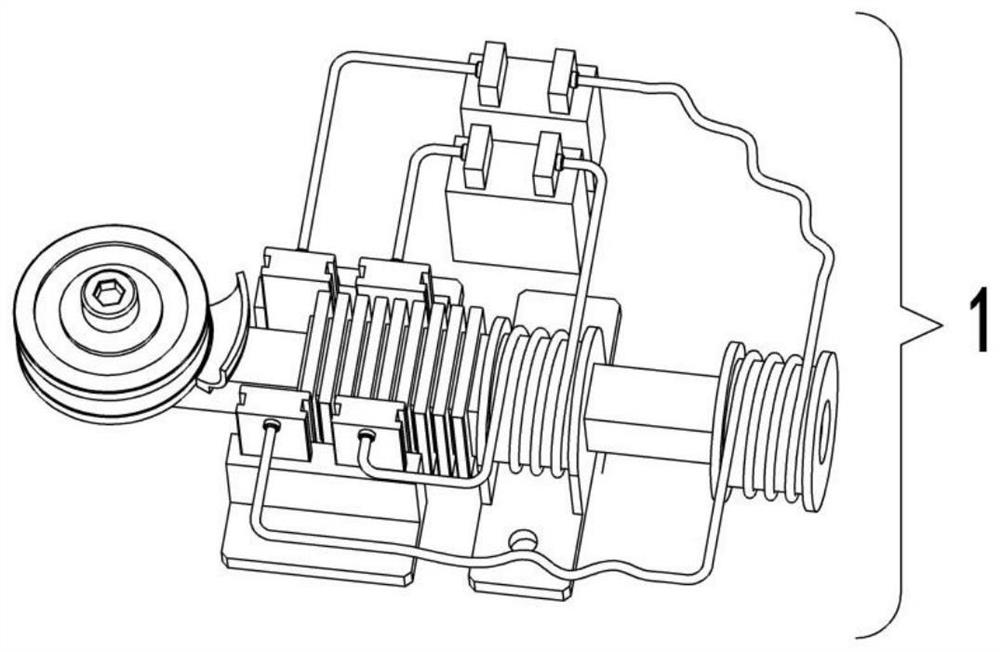

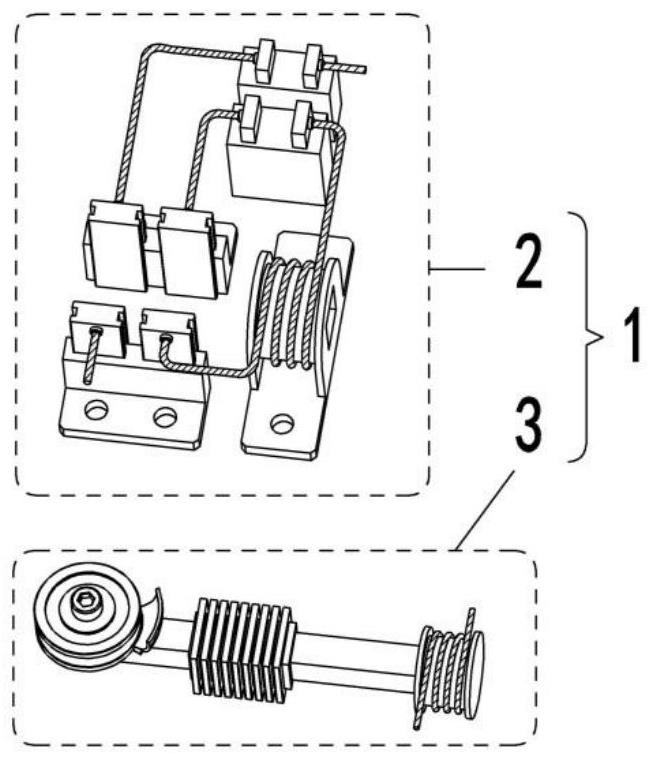

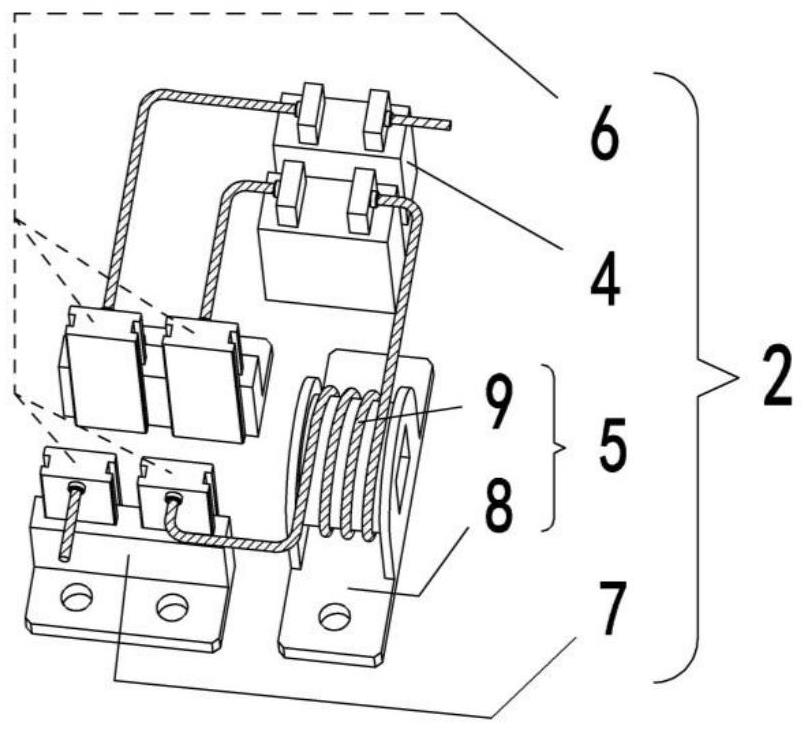

[0037] Such as figure 1 and figure 2 As shown, the unloading and variable resistance damping structure 1 includes a fixed module 2 and a mobile module 3, the mobile module 3 is movably fitted on the fixed module 2, one end of the mobile module 3 is connected to a steel wire rope 17, and the other end is suspended in the air or subjected to the impact and extrusion of an external object The external object contacts and pushes the mobile module 3 to move relative to the fixed module 2, driving the mobile module 3 to move with variable resistance, realizing the unloading of the wire rope, and then realizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com