Drilling machine drilling device with dust falling function

A drilling device and functional technology, which is applied in the field of drilling rigs, can solve problems such as lack of cleaning, affecting the service life of drill pipes, and harsh working environments, and achieve the effects of increasing service life, reducing dust, and good dust reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

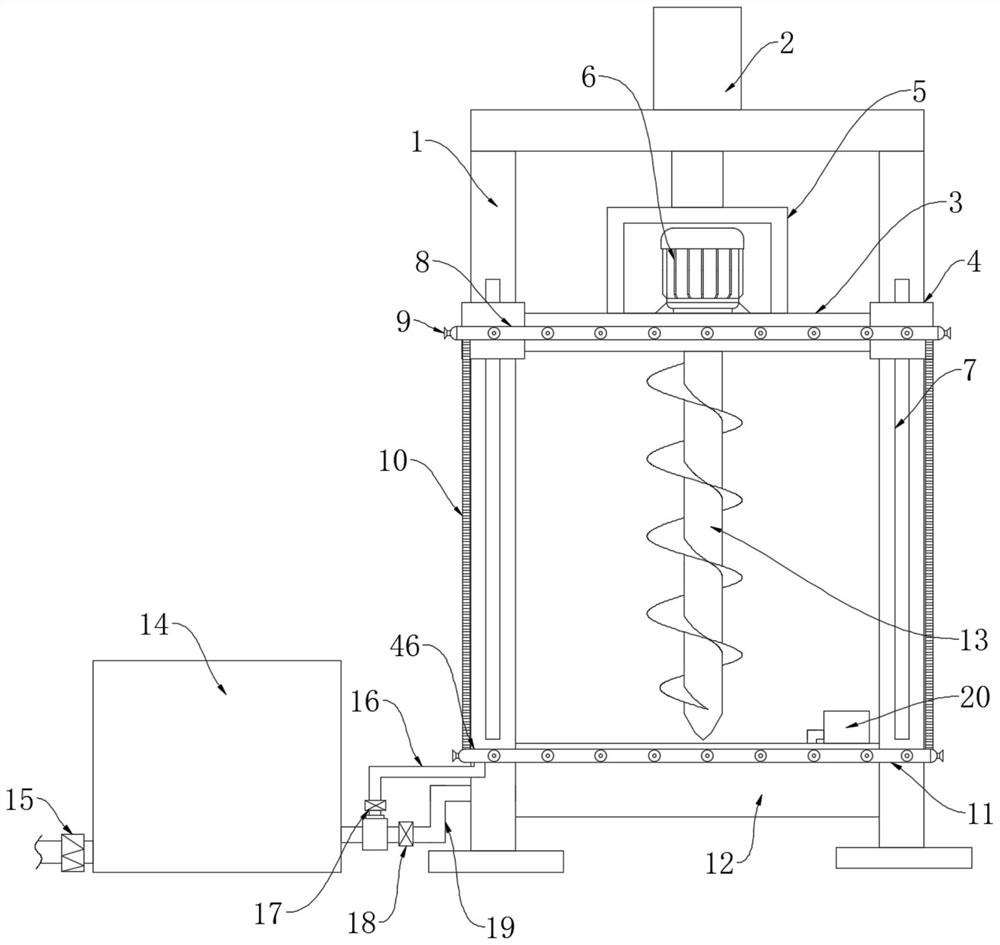

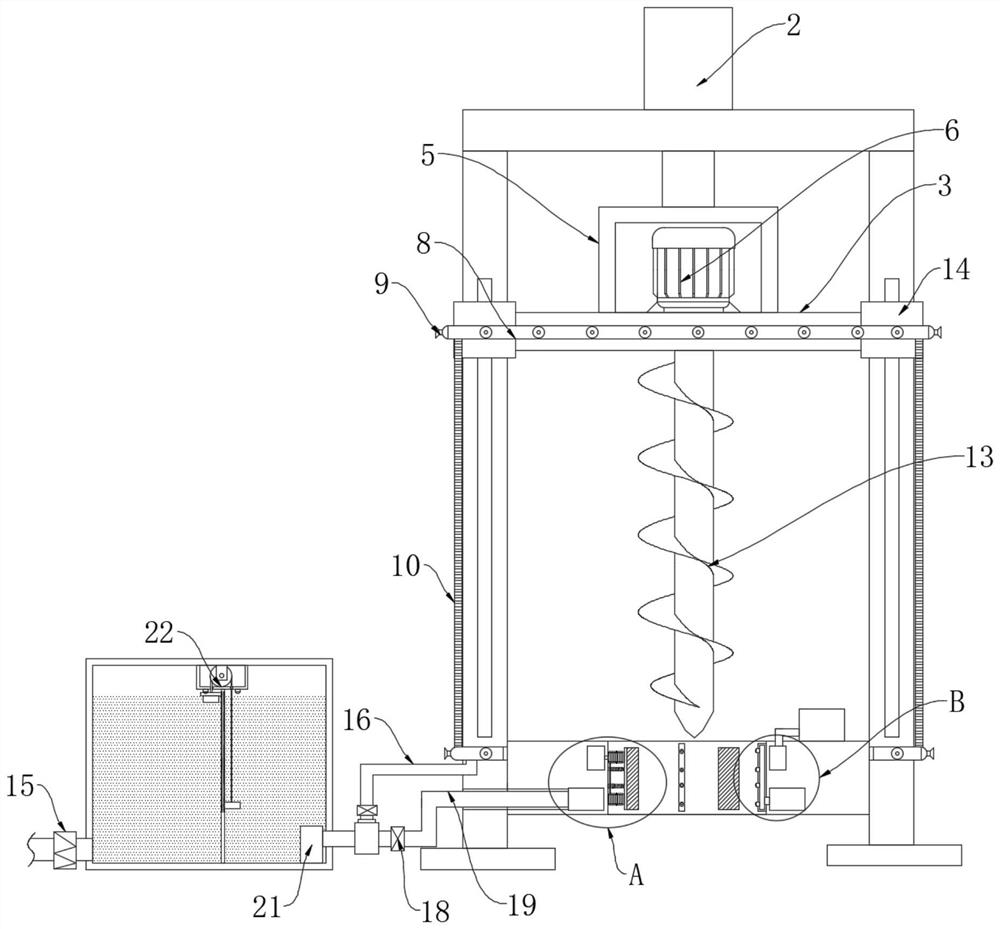

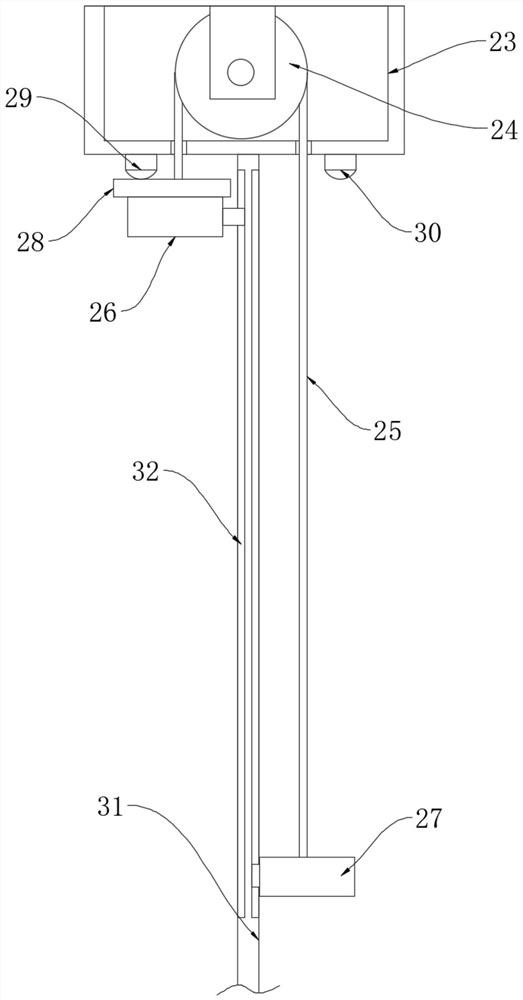

[0031] Such as Figure 1-7 As shown, a drilling device with dust suppression function includes a portal frame 1, a hydraulic cylinder 2, a lifting seat 3, an auger drill rod 13, an automatic water replenishment mechanism 22, a flushing assembly 43, a cleaning assembly 44 and a dust suppression assembly 46 , the hydraulic cylinder 2 is fixedly installed on the top of the portal frame 1, the lifting seat 3 is slidably installed on the portal frame 1, the upper end of the lifting seat 3 is provided with a motor cover 5, and the inside of the motor cover 5 is provided with a drive motor 6, and the drive motor 6 The output shaft of the hydraulic cylinder 1 is connected with the auger rod 13, the auger rod 13 is located under the lifting seat 3, the extension end of the hydraulic cylinder 2 is connected with the motor cover 5, a water storage tank 14 is provided on one side of the portal frame 1, and a water storage tank 14 is provided on one side A replenishment pump 15 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com