Test system for simulating installation load of upper bending section in horizontal laying process of umbilical cable

A test system and umbilical cable technology, which is applied in the field of marine engineering, can solve the problems of difficulty in simulating installation tests, rarely seen technical research, etc., and achieve the effects of reducing test costs, wide adjustment range, and precise movement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

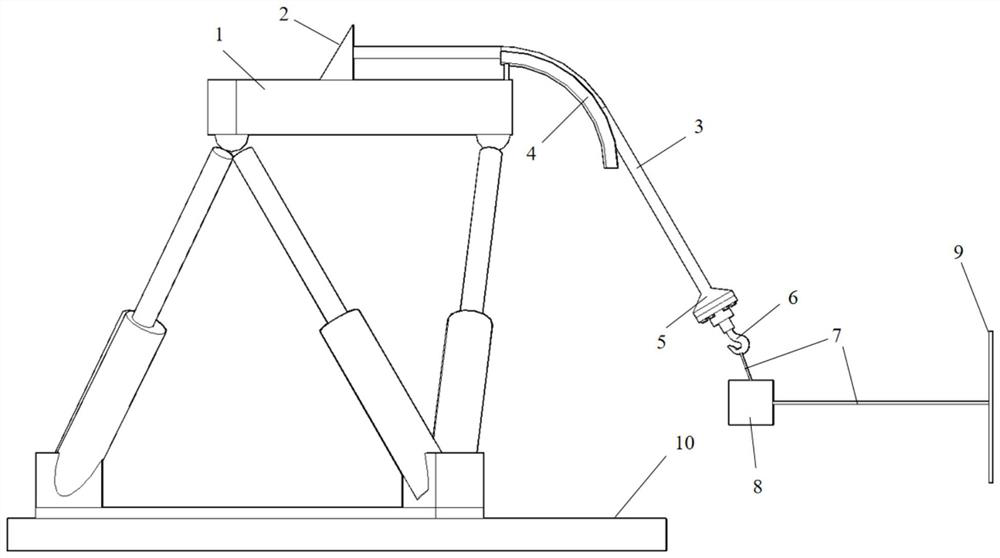

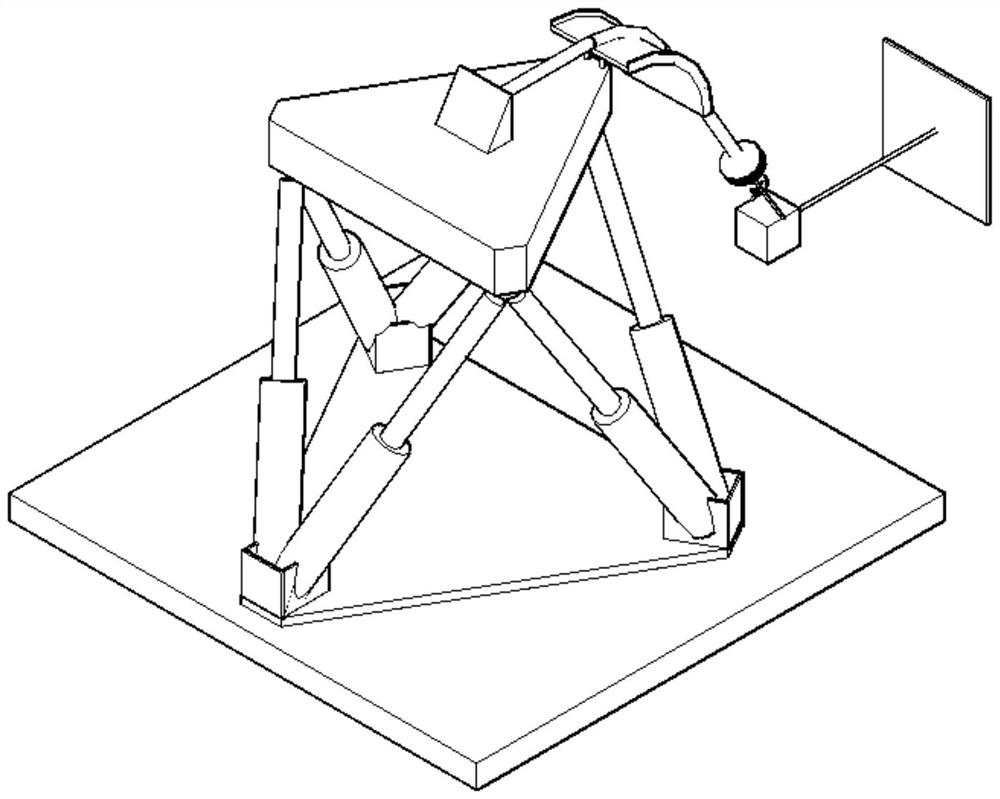

[0029] Firstly, the scaling ratio is calculated according to the test requirements, and the launching bridge 4 and the test cable 3 are made according to the ratio. The six-degree-of-freedom motion platform 1 is installed on the laboratory floor 10, and is connected and debugged with the supporting host computer. After the debugging, other parts of the test device are installed. First fix the fixed end 2 above the upper platform of the six-degree-of-freedom motion table 1 through two bolts 11, and the clamp part of the fixed end 2 is used to fix the test cable 3; then install the lower bridge 4 on the upper platform of the six-degree-of-freedom motion table 1 At the edge of one end, note that the radius and material of the lower bridge 4 should be consistent with the lower bridge in the prototype experiment; the pressure sensor 13 is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com