Power operation test device suitable for flexible direct current transmission converter valve submodule

A flexible DC power transmission and operation test technology, applied in the field of DC power, can solve the problems of high heat generation and inability to adjust heat dissipation, and achieve the effect of good heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

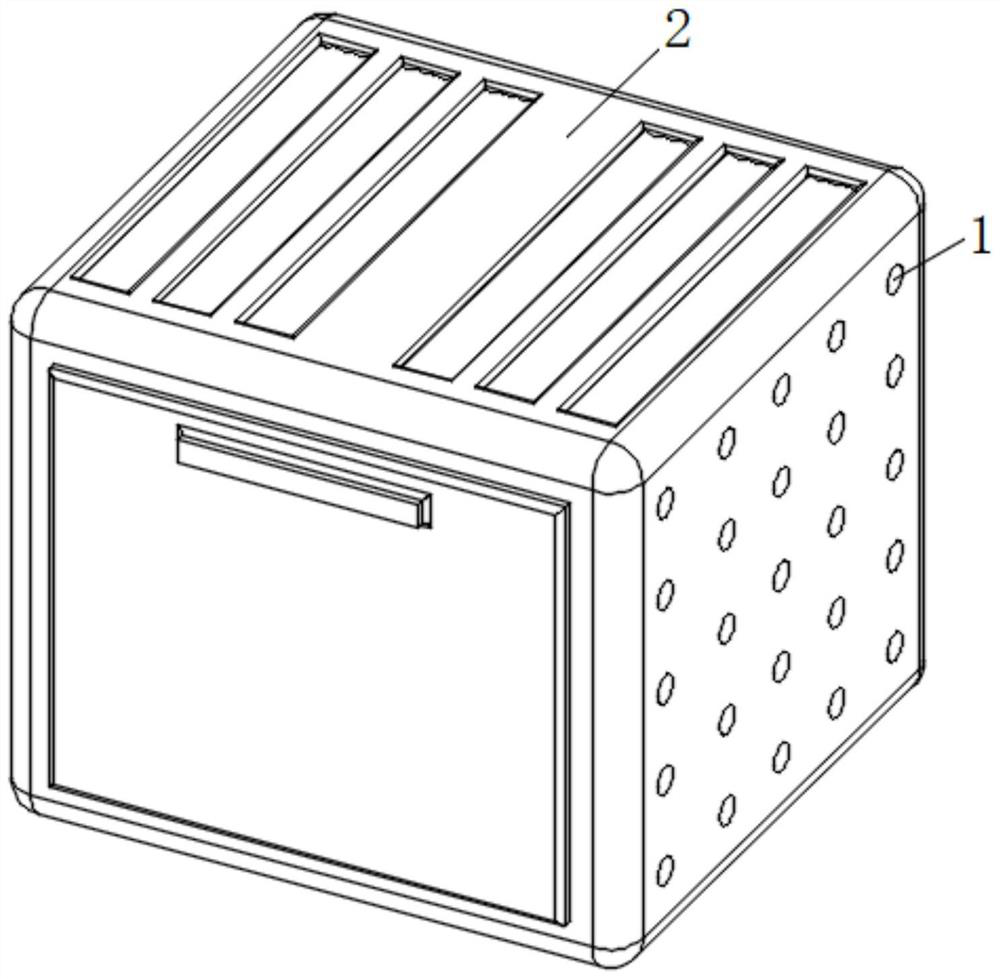

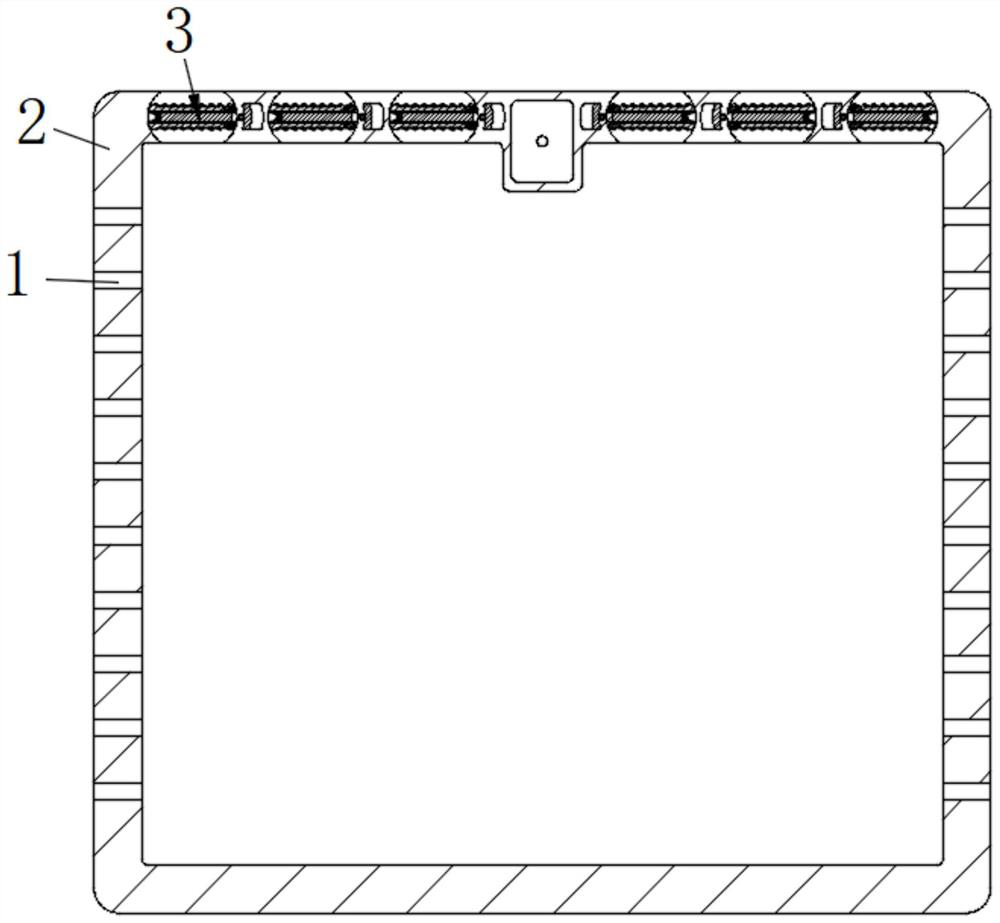

[0026] see Figure 1-5 , the present invention provides a technical solution: a power operation test device suitable for flexible direct current transmission converter valve sub-modules, including a test equipment body 2, an air groove is provided inside the test equipment body 2, and the inside of the air groove communicates with the inside of the chute 305 , there are heat dissipation holes 1 on both sides of the test equipment body 2, and a rotating opening and closing heat dissipation mechanism 3 is arranged inside the test equipment body 2;

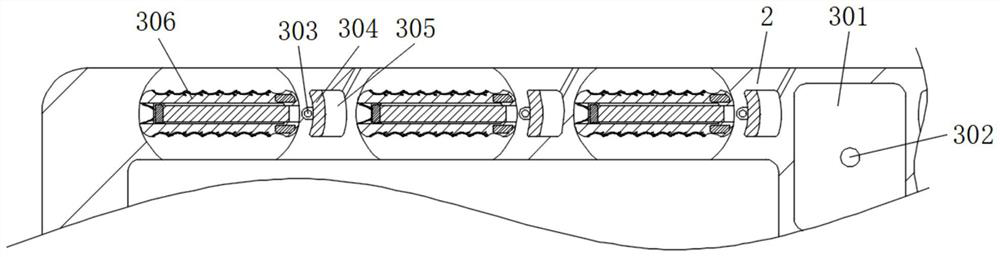

[0027] The rotary opening and closing heat dissipation mechanism 3 comprises an air storage tank 301, an air inlet 302, an air outlet 303, a magnet slider 304, a chute 305, a rotating plate 306, a magnetic block A307, and the side of the magnetic block A307 opposite to the magnet slider 304 The magnetism is heteropolar, the air storage tank 301 is set inside the test equipment body 2, the air inlet hole 302 is set inside the air stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com