Production scheduling method and system based on order allocation, electronic equipment and storage medium

A technology for production scheduling and ordering, applied in the field of automation, can solve problems such as unreasonable leakage scheduling, reduce the frequency of changing lines, and overcome the effects of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

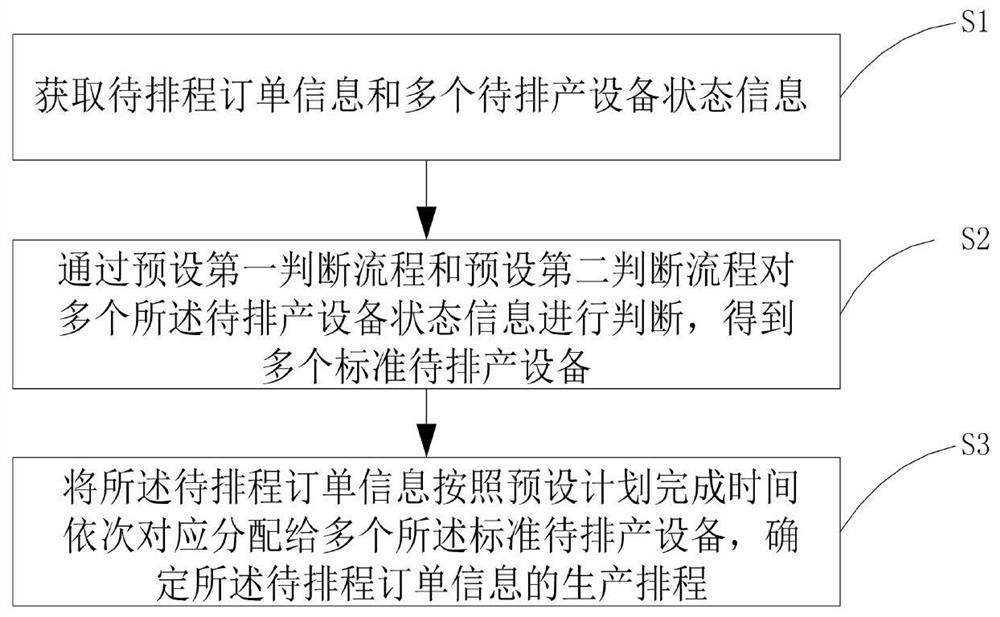

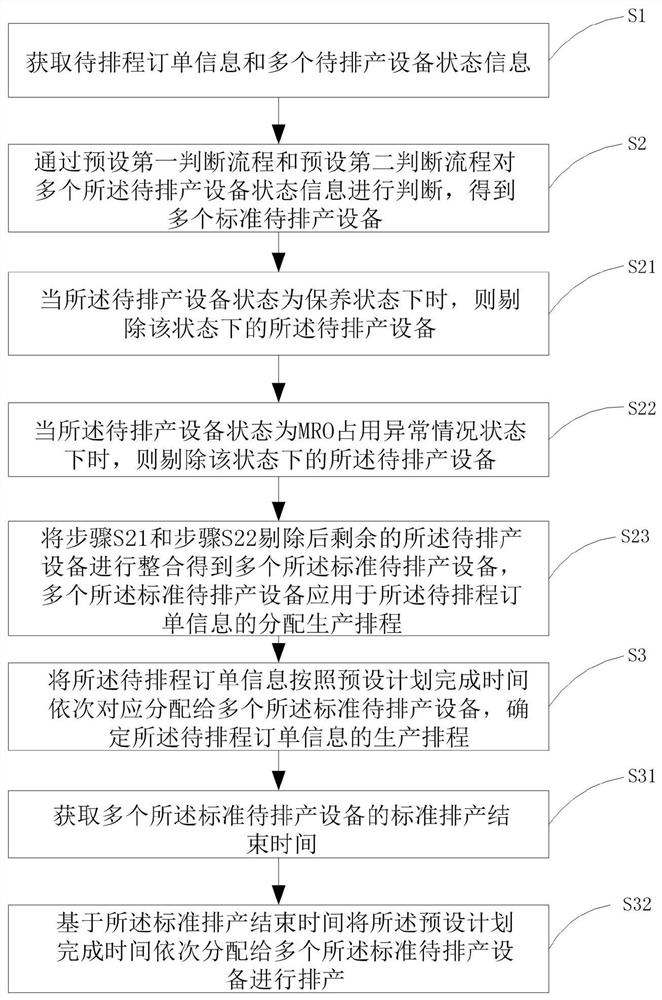

[0046] This embodiment provides a production scheduling method based on order allocation, such as figure 1 and figure 2 As shown, the method includes the steps of:

[0047] S1: Acquiring the order information to be scheduled and the status information of multiple equipment to be scheduled;

[0048] S2: Judging the status information of multiple equipment to be scheduled through the preset first judgment process and the preset second judgment process, and obtaining multiple standard equipment to be scheduled;

[0049] S3: Assign the information of the order to be scheduled to multiple standard equipment to be scheduled in sequence according to the preset planned completion time, and determine the production schedule of the order to be scheduled.

[0050] Specifically, according to the planned start time of the order, the order is sorted from small to large, and the order is scheduled one by one in order to reduce the frequency of line changes. Through the preset first judgm...

Embodiment 2

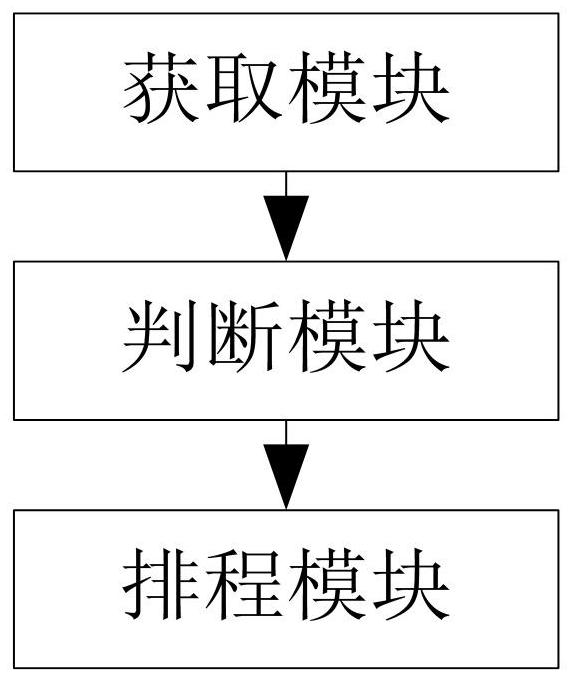

[0065] This embodiment provides a production scheduling system based on order allocation, such as image 3 and Figure 4 As shown, the system includes:

[0066] A production scheduling system based on order allocation, including:

[0067] Obtaining module: used to obtain information about orders to be scheduled and status information of multiple equipment to be scheduled;

[0068] Judgment module: judge the status information of multiple equipment to be scheduled through the preset first judgment process and the preset second judgment process, and obtain multiple standard equipment to be scheduled;

[0069] Scheduling module: It is used to assign the information of the order to be scheduled to multiple standard equipment to be scheduled according to the preset completion time, and determine the production schedule of the order to be scheduled.

[0070] Wherein, the information of the order to be scheduled includes the order number, the quantity of the product, the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com