Application of carbon fiber on the grass-mowing machine

A lawnmower and carbon fiber technology, applied in applications, hand-held lawn trimmers, harvesters, etc., can solve the problems of low strength, inconvenient operation, poor wear resistance of nylon materials, etc., and achieve improved strength and wear resistance , prolong the service life and reduce the frequency of line change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

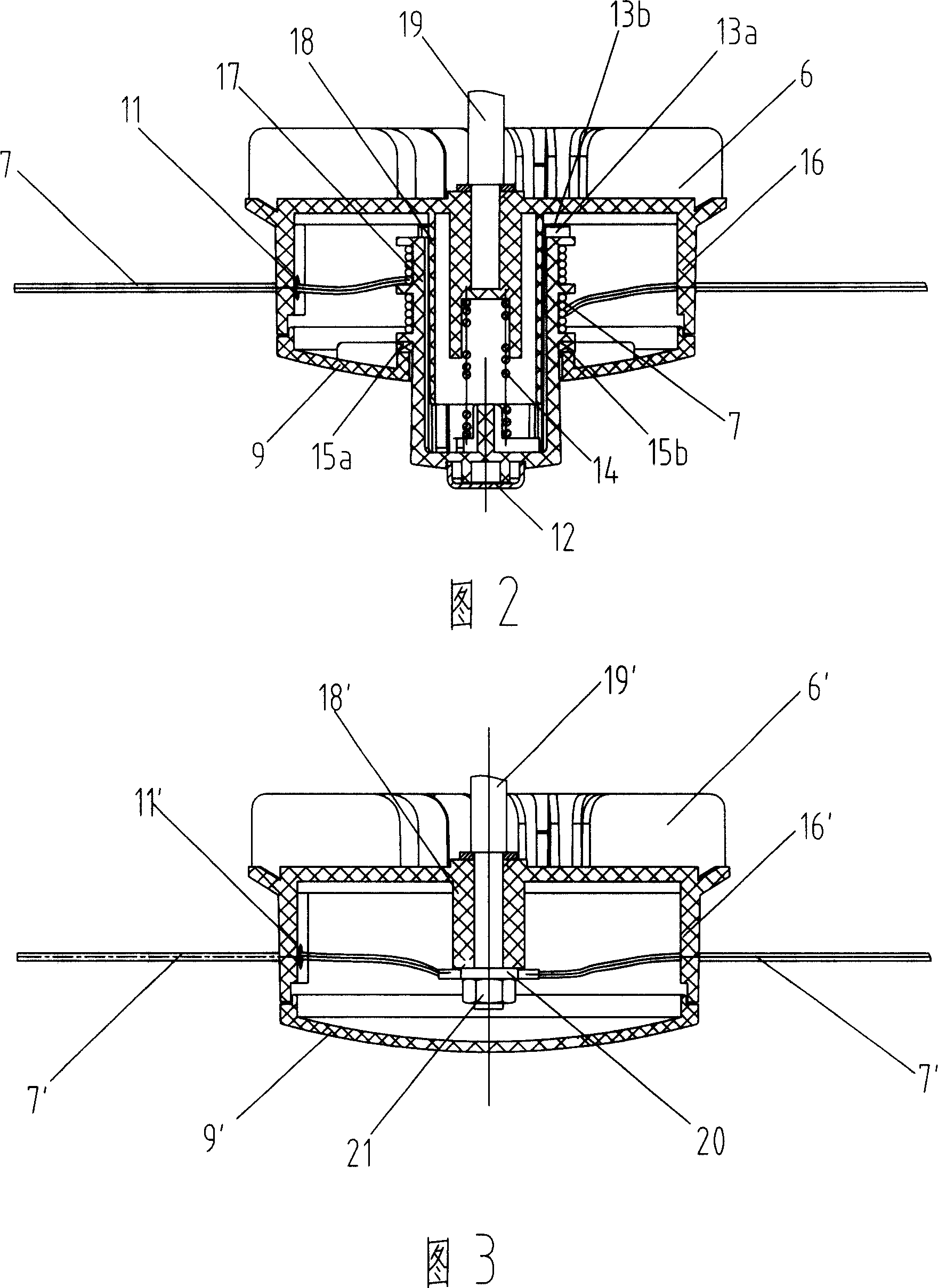

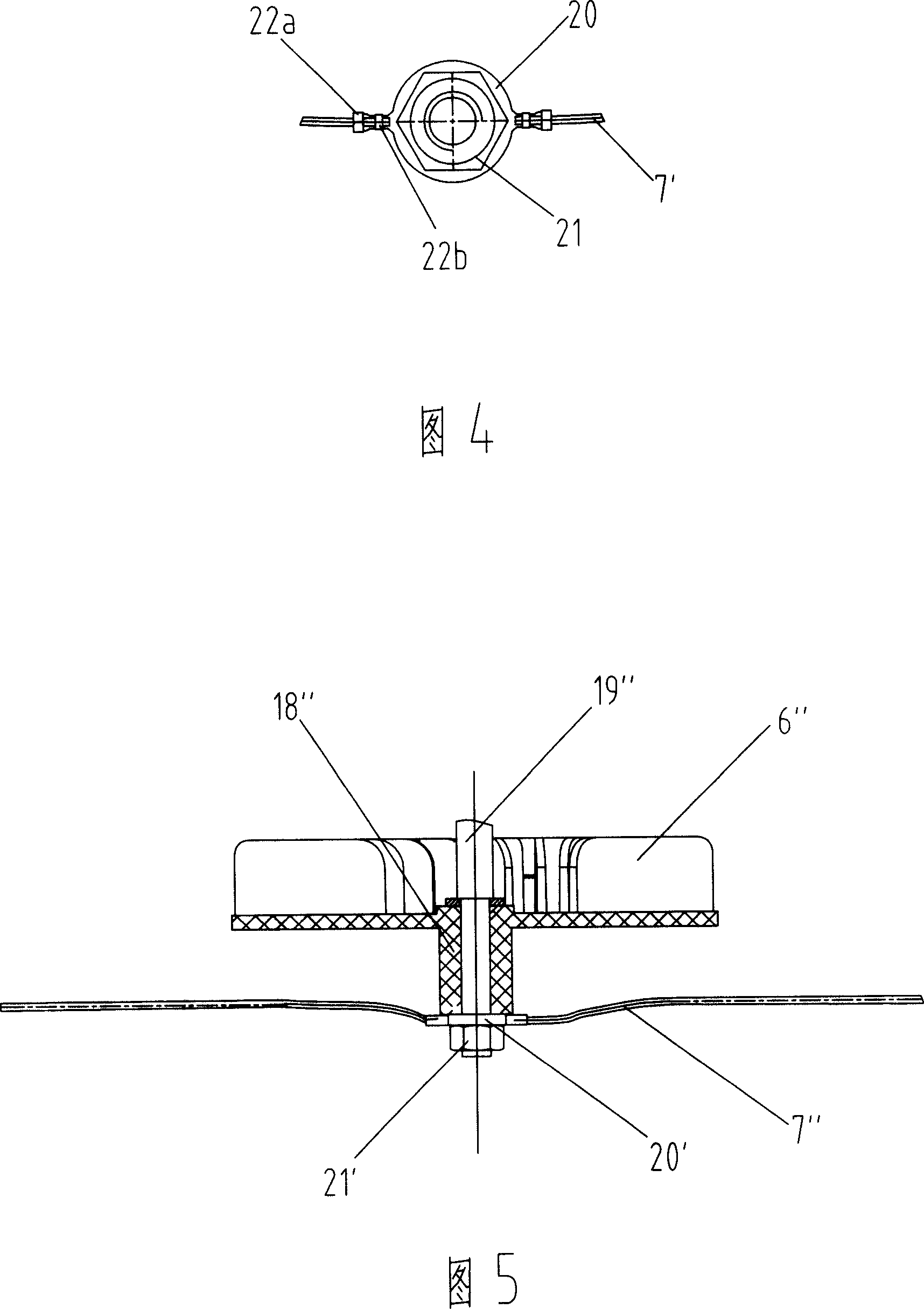

[0023] The present invention discloses a grass trimmer device suitable for use of carbon fiber wire as a cutting wire. Since the grass trimmer adopts a carbon fiber cutting wire, the life of the cutting wire is longer than that of ordinary nylon cutting wire. Therefore, the wire reel can be made smaller or the cutting operation can be performed conveniently without a wire reel, which will now be described with specific embodiments.

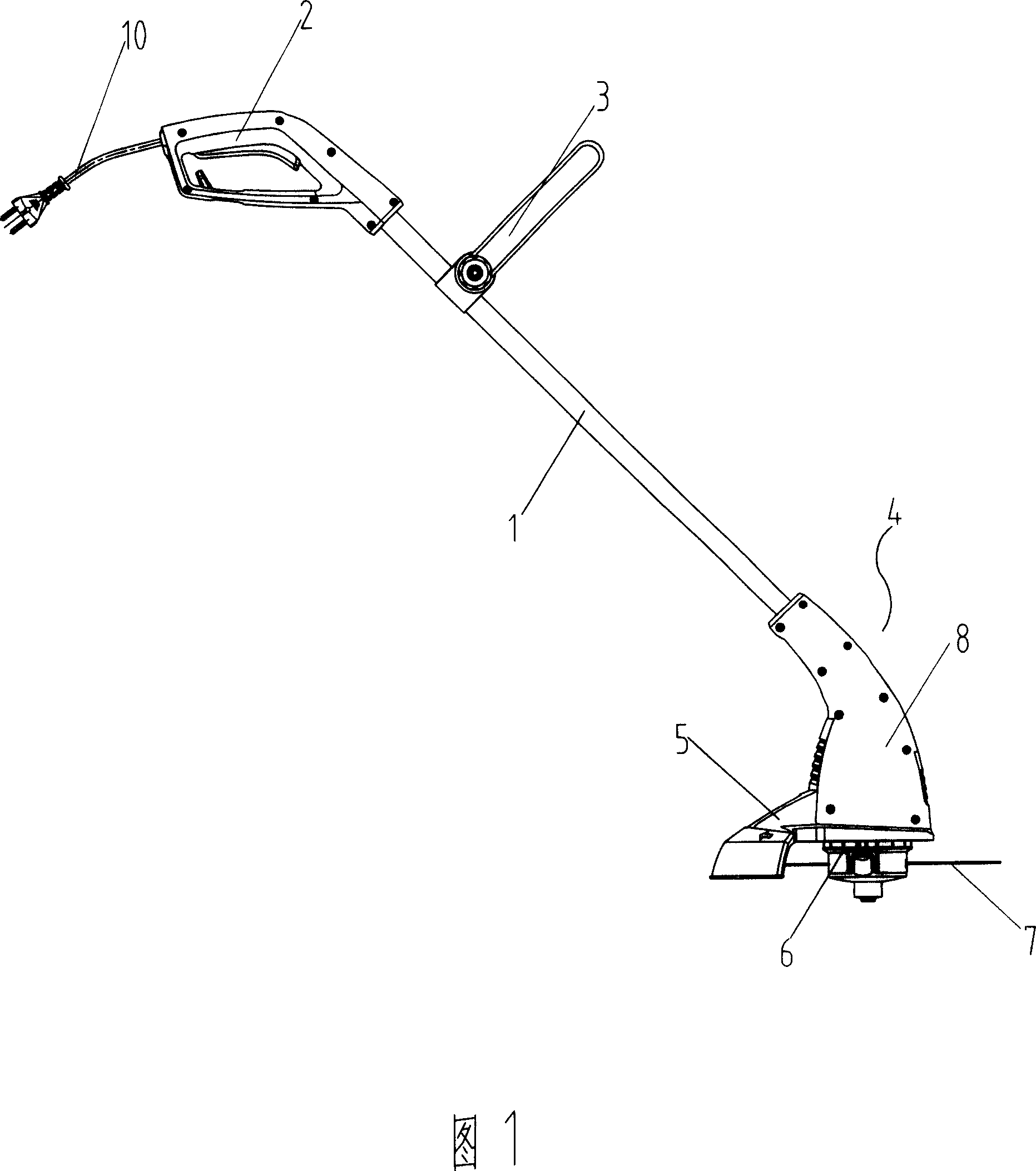

[0024] Referring to Fig. 1, it is a traditional electric mower, including a longitudinally extending operating lever 1, one end of the operating lever 1 is provided with a main handle 2, and the position of the operating lever 1 close to the main handle 2 is pivoted. A pair of handles 3 is provided, the tail of the main handle 2 is provided with a connecting wire 10 for connecting to a power supply, and the other end of the operating rod 1 is provided with a working head 4, which includes a motor (not shown) for accommodating the motor. The casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com