Novel grouping structure of large cylindrical battery cells

A group structure and cell group technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as uneven heating of cells, failure of power supply circuits, and poor experience, and achieve easy temperature and balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

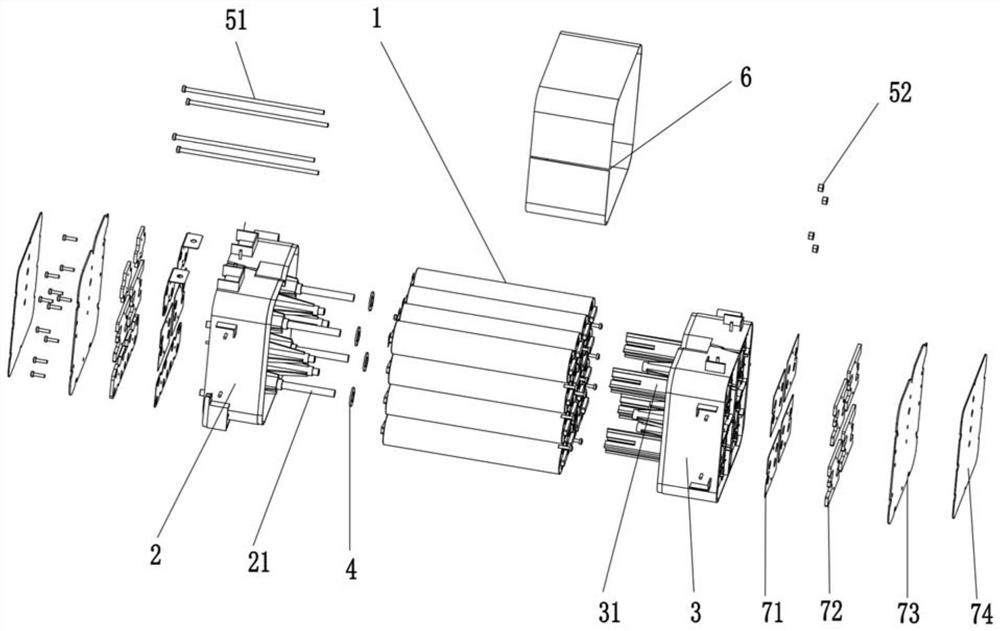

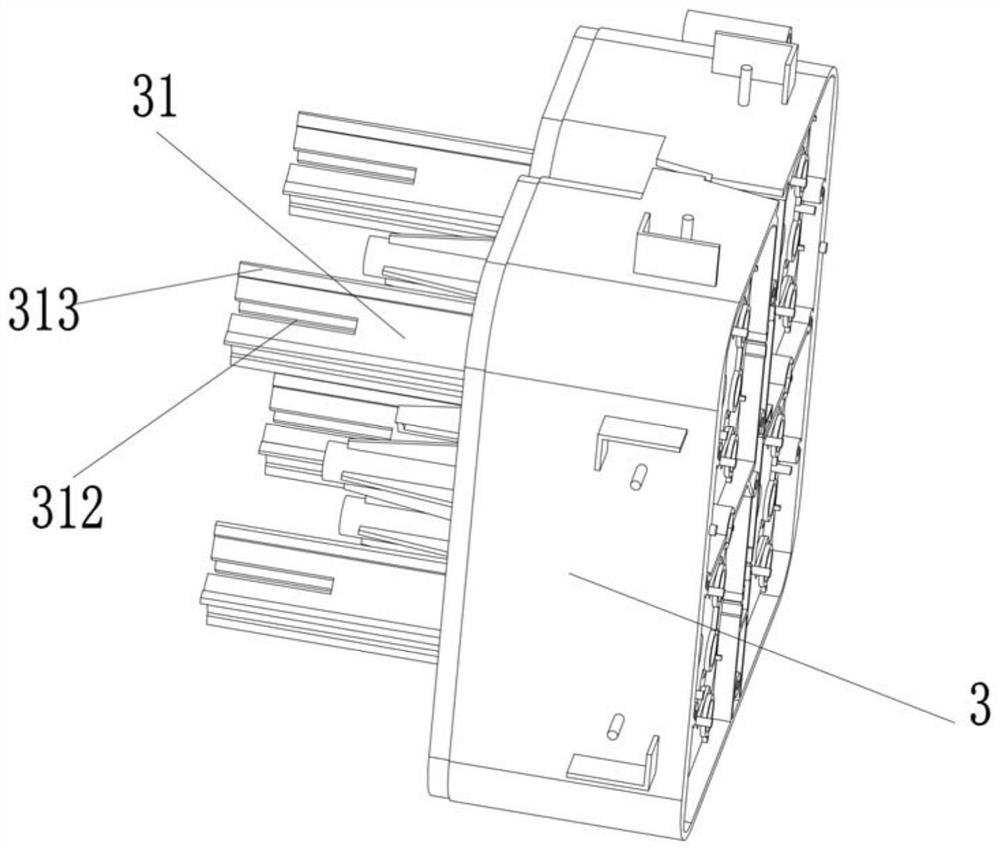

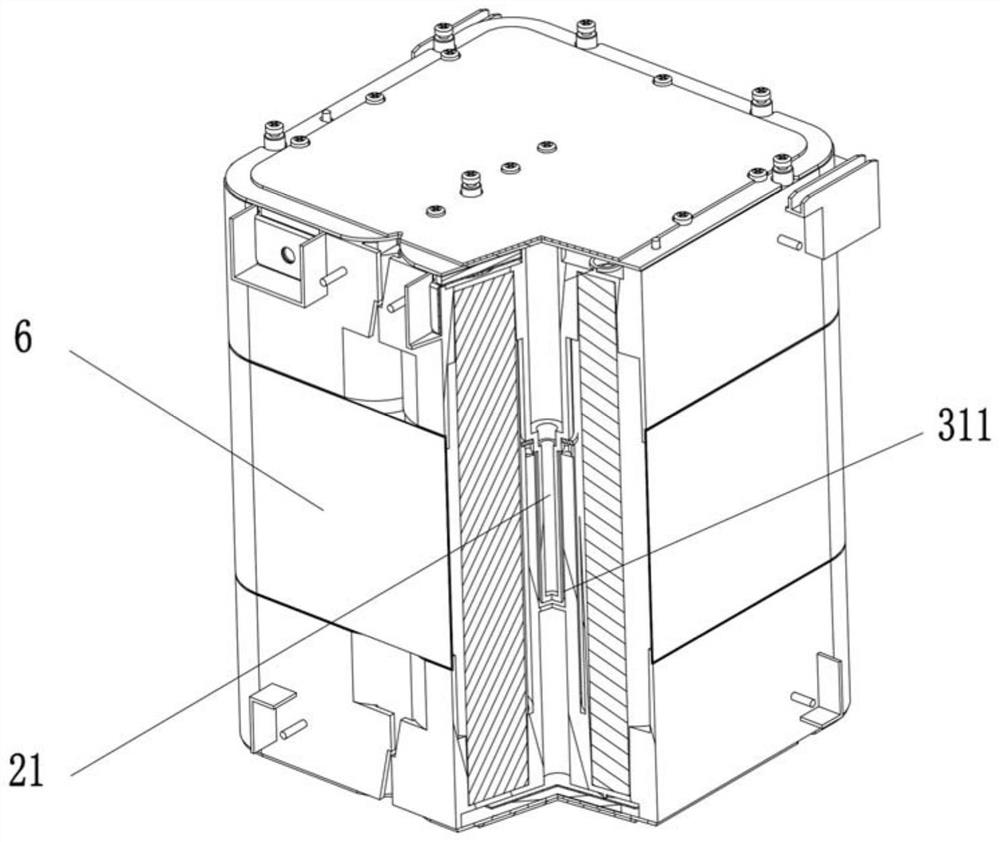

[0030] Such as Figure 1-5 As shown, a new group structure of a large cylindrical battery cell includes a battery cell group composed of several battery cells 1 and upper brackets 2 and lower brackets 3 at both ends; the upper bracket 2 and the middle of the lower bracket 3 are respectively provided There are a number of filling columns 21 and filling columns 31 that cooperate with each other; the filling columns 21 are provided with a gasket 4 that interferes with the side wall of the battery cell 1 in the circumferential direction; the center of the filling column 31 is provided with the filling column 21 Coordinated glue filling holes 311; glue is provided in the glue filling holes 311; busbars 71 are arranged at both ends of the battery pack; thermal pads 72, heating films 73, Insulation pad74.

[0031] In one embodiment of the present invention, the upper end of the glue filling column 31 is provided with several glue overflow grooves 312 communicating with the glue fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com