Feeding bottle cleaning, drying and warming all-in-one machine

An all-in-one machine and milk-warming technology, which is applied in the washing machine/washing machine for tableware, the parts of the washing machine/rinsing machine for tableware, cleaning equipment, etc. The effect of reduced power consumption and water consumption, easy portability and mobility, and high structural integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

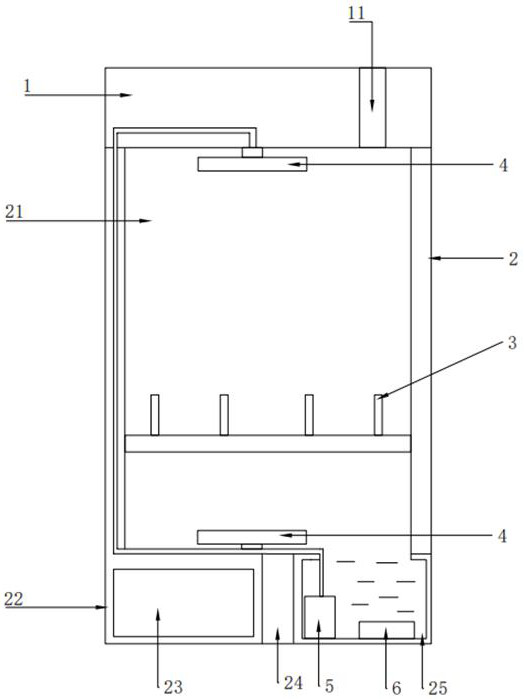

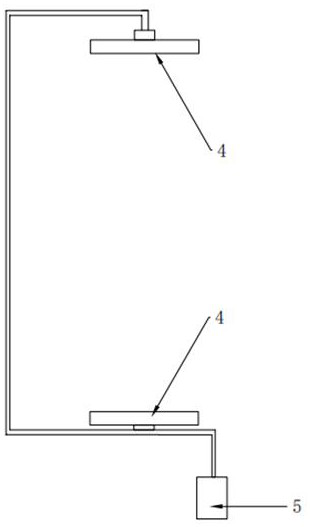

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 with 2 As shown, the present invention provides a baby bottle cleaning, drying and warming machine, which includes a top cover 1 and a machine body 2; the machine body 2 is provided with an internal chamber 21, and the internal chamber 21 is used to accommodate a baby bottle or a pacifier; The top of the chamber 21 is provided with an opening for putting in and taking out feeding bottles or pacifiers and the like, and a basket 3 is arranged between the side walls of the inner chamber 21, and the basket 3 is used for fixing feeding bottles or pacifiers and the like to prevent During the process of cleaning, drying and warming milk, the feeding bottle is displaced, causing damage to the feeding bottle or nipple or causing milk to leak;

[0025] The upper cover 1 is detachably sealed and connected to the opening. The sealed connection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com