Novel skin stitching instrument

A suturing device and skin technology, applied in the field of skin suturing devices, can solve the problems of skin damage, secondary wound injury, collapse and other problems of suturing nail wounders, and achieve the effects of avoiding poor wound suturing effect, convenient output, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

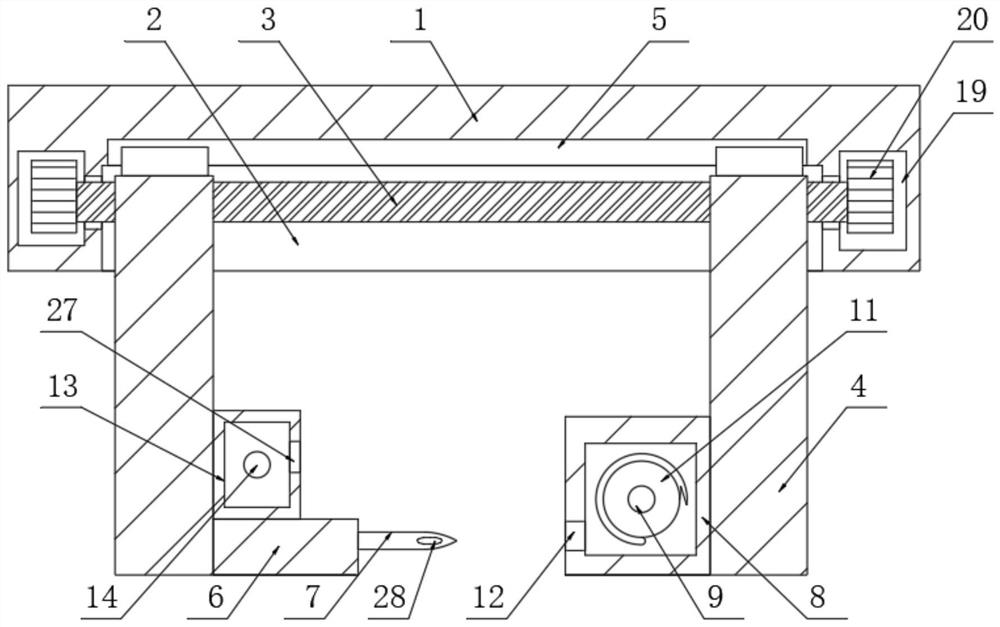

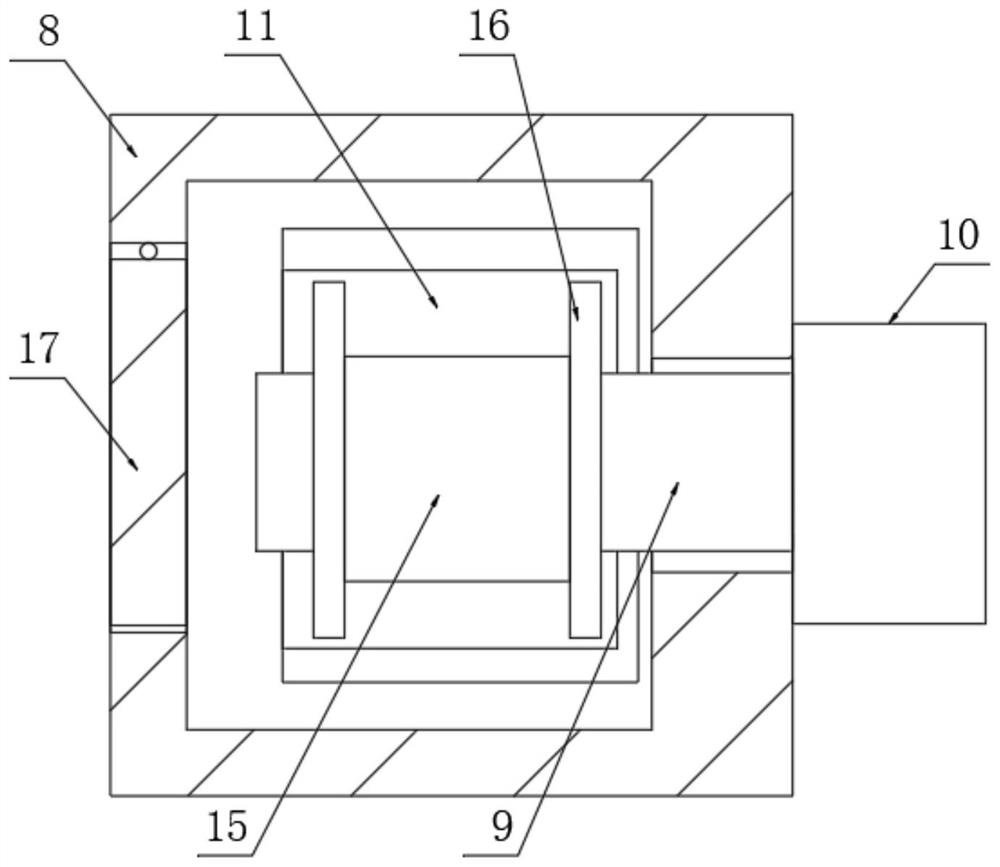

[0028] like figure 2 and image 3 As shown, it includes a casing 1, a groove 2 is provided on the left side of the lower surface of the casing 1, and a threaded rod 3 is rotatably connected to the front and rear sides of the inner wall of the groove 2, and the rod wall of the threaded rod 3 is threadedly connected with a moving block 4. The upper side of the inner wall of the groove 2 is provided with a chute 5, the inner wall of the chute 5 is slidably connected with the upper surface of the moving block 4 through the slider, and the front surface of the rear moving block 4 is fixedly connected with a pin Block 6, the front side surface of the pin block 6 is fixedly connected with a needle head 7, the left side surface of the needle head 7 is provided with a wire inlet hole 28, and the rear side surface of the front side moving block 4 is fixedly connected with a pressure shell 8, the pressure shell 8 There is a rotating device inside, the rotating device includes a first r...

specific Embodiment 2

[0030] like image 3 and Figure 4 As shown, the upper surface of the pin block 6 is fixedly connected to the wire harness shell 13, the rear side of the inner wall of the wire harness shell 13 is fixedly connected with a support rod 14, and the rod wall of the support rod 14 and the rod wall of the first rotating rod 9 are sleeved. There is a take-up coil 15, the left and right sides of the take-up coil 15 are fixedly connected with wire baffles 16, the front side surface of the wire harness shell 13 is provided with a wire outlet 27, the left side surface of the pressure shell 8 and the left side surface of the wire harness shell 13 are both. The door body 17 is rotatably connected, and the left side surfaces of the two door bodies 17 are fixedly connected with a lock head 18, which is convenient for replacing the suture thread with a new one. line output.

specific Embodiment 3

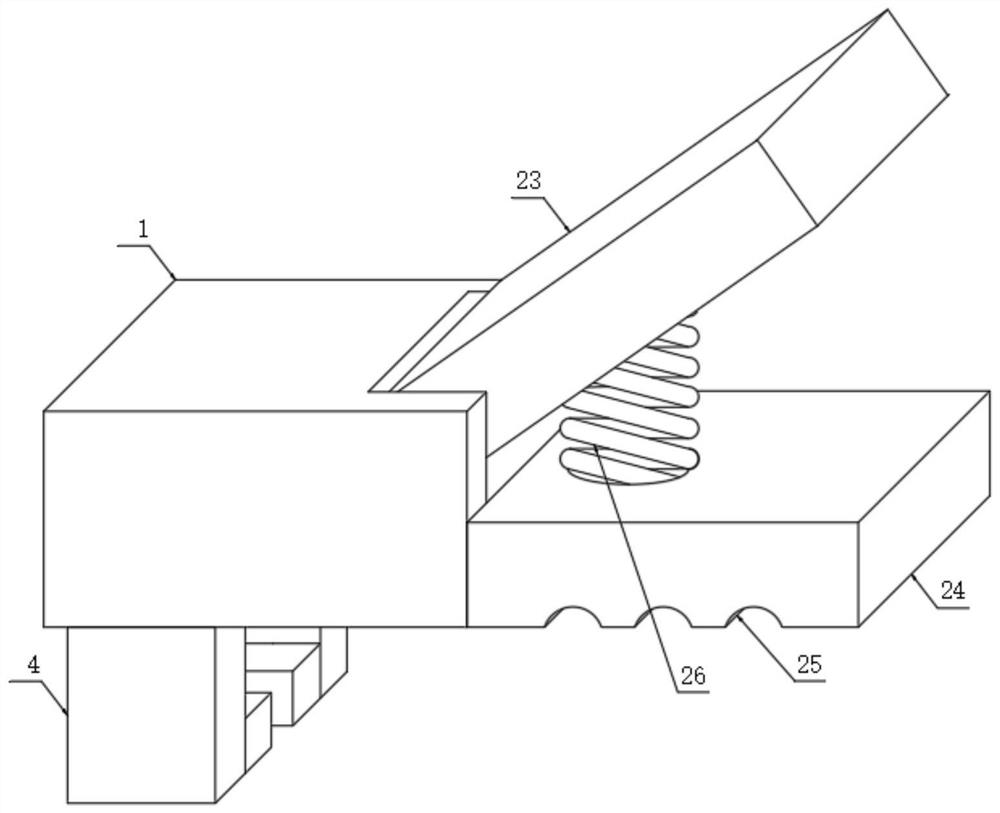

[0032] like Figure 5 and with Image 6 As shown, the front and rear sides of the upper surface of the casing 1 are provided with cavities 19, and the front and rear ends of the threaded rod 3 respectively penetrate the front and rear sides of the inner wall of the groove 2 to the interior of the cavity 19. Both ends are fixedly connected with the first spur gear 20 , the rear side of the inner wall of the casing 1 is rotatably connected with a second rotating rod 21 , and the front and rear ends of the second rotating rod 21 respectively penetrate the front and rear sides of the inner wall of the casing 1 to the cavity 19 Inside, the front and rear ends of the cavity 19 are fixedly connected with the second spur gears 22, the left side surfaces of the two first spur gears 20 and the right side surfaces of the second spur gears 22 are connected through the rack rotation, and the second The rod wall of the rod 21 is fixedly connected with a pressing rod 23, which drives the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com