Multi-station rotary table

A multi-station, turntable technology, applied in the direction of the injection device, can solve the problems of troublesome operation, high setting cost, inconvenient application, etc., and achieve the effect of neat layout and good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

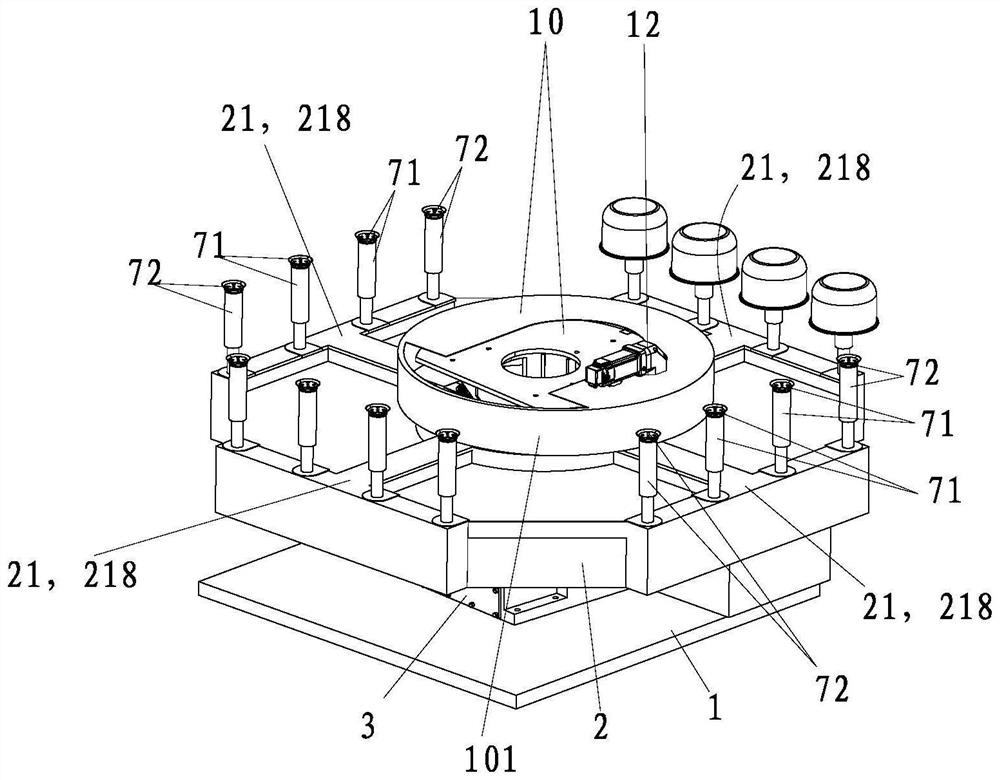

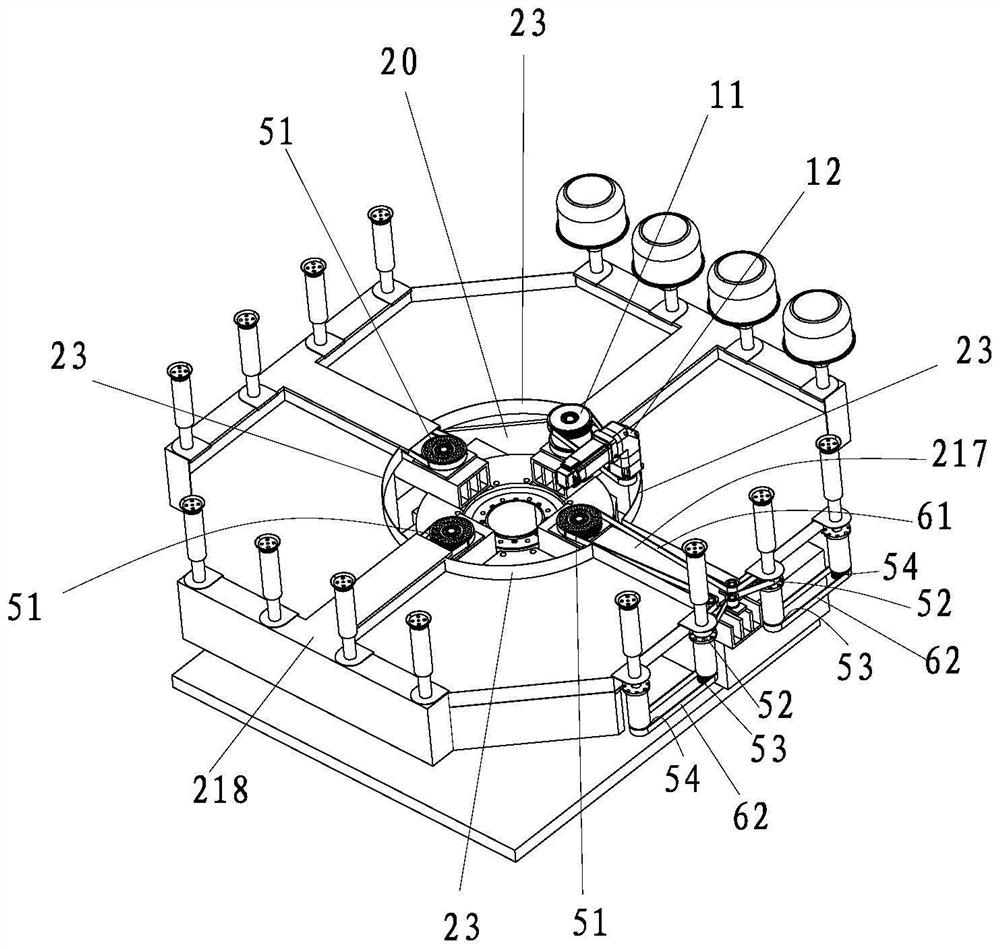

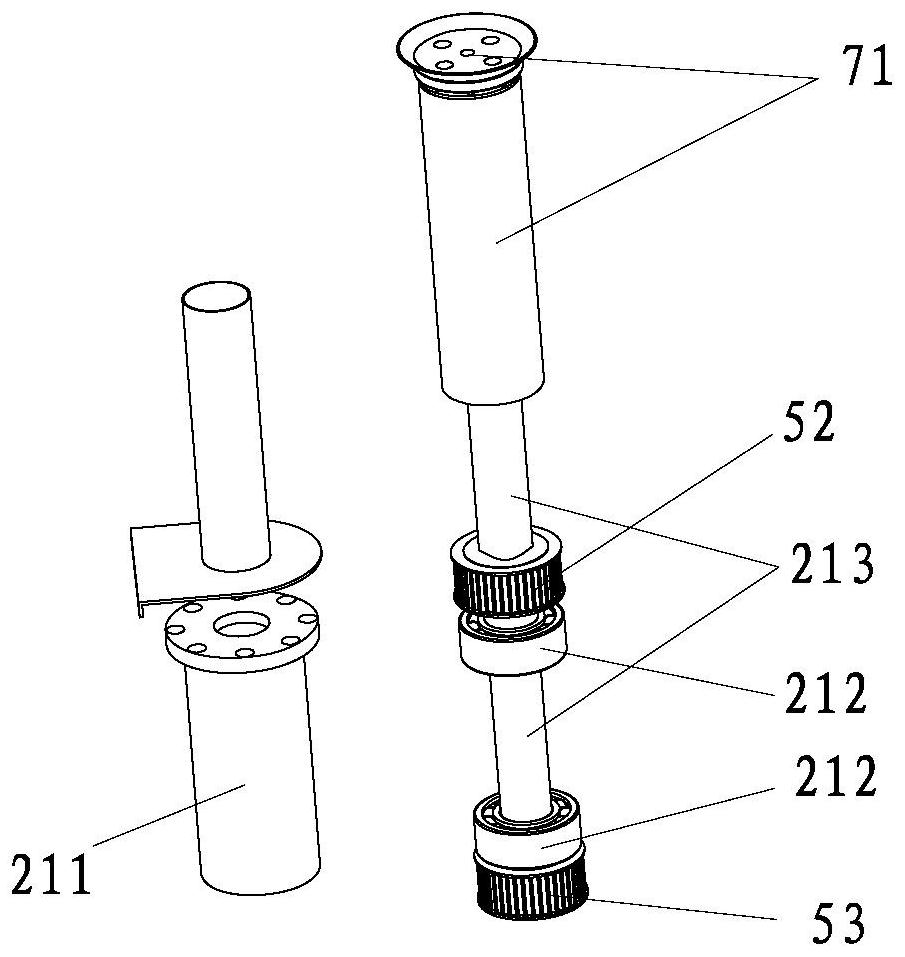

[0025] Such as Figure 1 to Figure 4 As shown, a multi-station turntable includes a base 1, a turntable 2 is installed on the base 1, a first motor drive mechanism 3 for driving the turntable 2 to rotate, and the turntable 2 is provided with 4 mounting parts 21 distributed in a circular array, each mounting part 21 is rotatably mounted with a first gear 51 close to the middle of the turntable 2 and a second gear 52 close to the outer periphery of the turntable 2, each mounting part 21 A first gear belt 61 is connected between the first gear 51 and the second gear 52, and a first sucker 71 that rotates with the second gear 52 is coaxially connected above the second gear 52. Adsorption side up.

[0026] As mentioned above, the structure of this case is simple and easy to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com