Vegetable refrigeration pretreatment device with slitting function

A vegetable and functional technology, which is applied in the field of vegetable refrigeration pre-treatment devices, can solve the problems of water loss in pulp and other problems, and achieve the effect of reducing water loss and water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

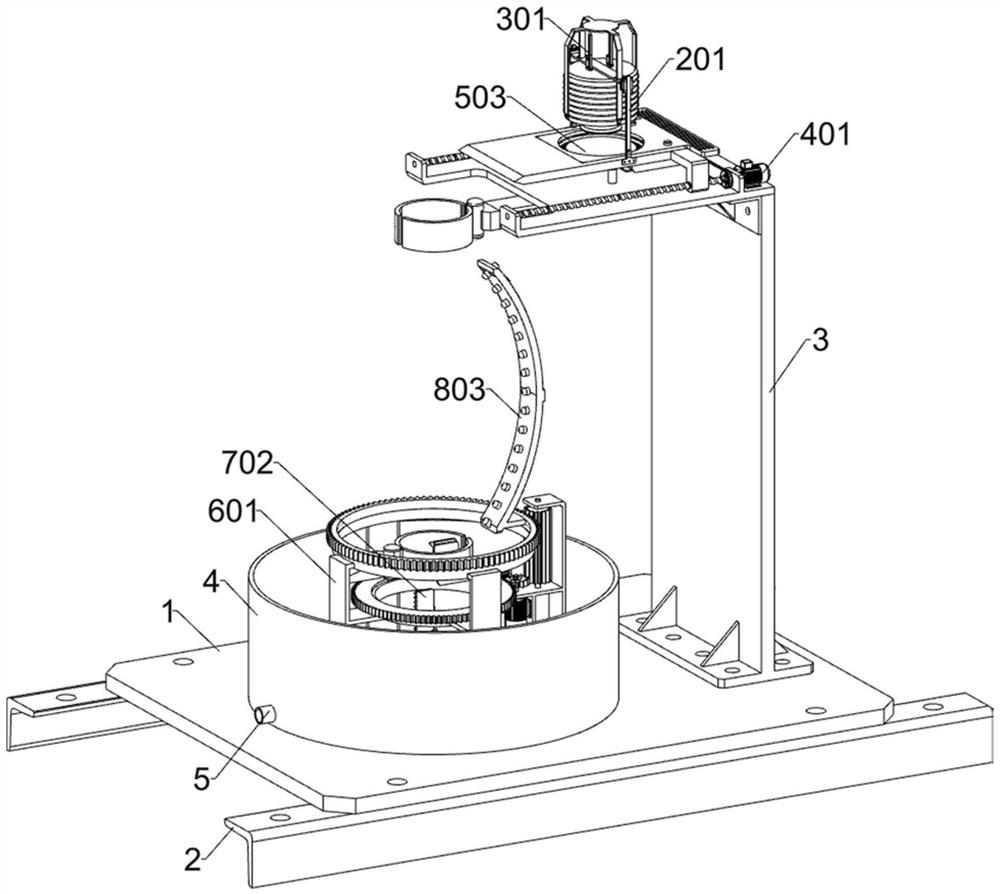

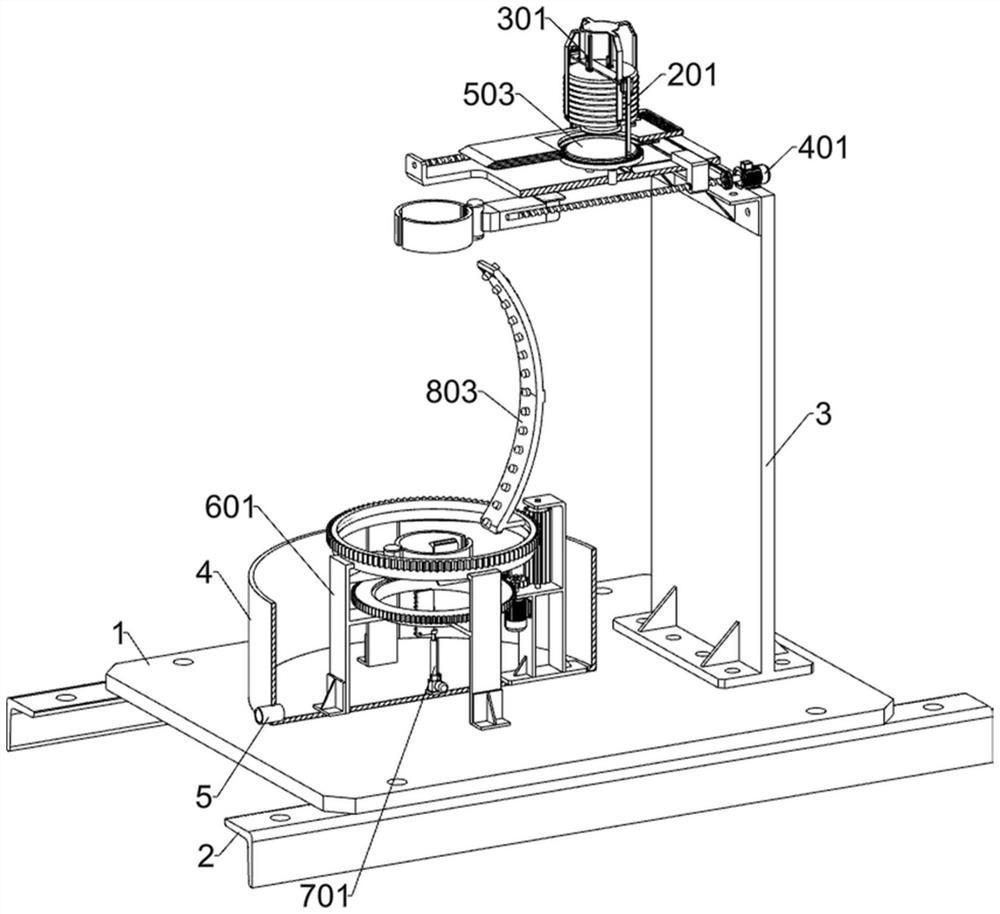

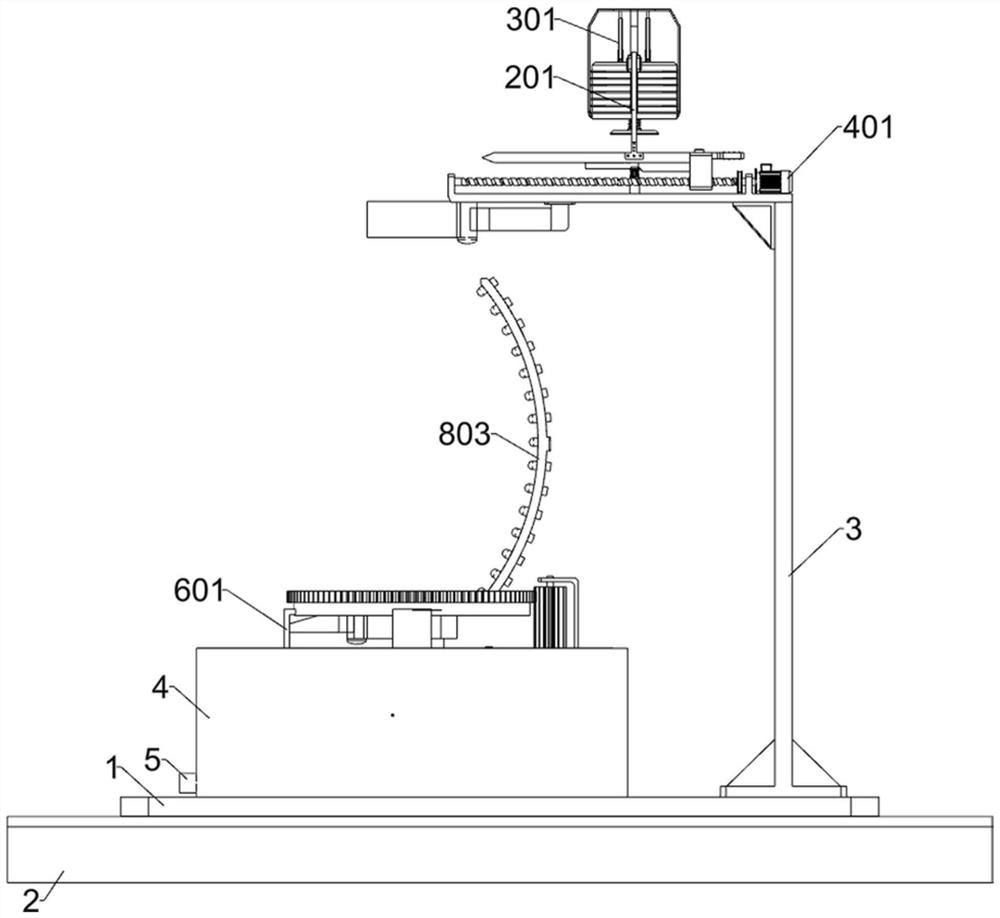

[0033] A pre-processing device for vegetable refrigeration with a cutting function, such as Figure 1-12As shown, it includes a bottom plate 1, a connecting frame 2, a first support frame 3, a storage box 4, a sewage pipe 5, a cladding component, a reinforcement component, a cutting component, a humidification component, a soil cleaning component and a first cleaning component; the bottom plate 1 A connecting frame 2 is bolt-connected to the front part of the lower side and the rear part of the lower side; the first support frame 3 is bolted to the upper right part of the bottom plate 1; the storage box 4 is fixedly connected to the left part of the upper side of the bottom plate 1; The lower part of the side is connected with the sewage pipe 5; the cutting assembly is installed on the upper side of the first support frame 3; the coating assembly is installed on the upper part of the cutting assembly; the reinforcement assembly is installed on the outside of the coating assembl...

Embodiment 2

[0042] On the basis of Example 1, such as figure 1 and Figure 13 As shown, it also includes a second cleaning assembly, the top of the soil cleaning assembly is installed with a second cleaning assembly, and the second cleaning assembly includes a second support ring 801, a second gear ring 802, a third linkage frame 803, a second water spray Head 804, transmission rod 805 and column gear 806; a second support ring 801 is welded between the upper part of the second support frame 601 at the front, the upper part of the second support frame 601 at the rear and the upper part of the second support frame 601 at the left The upper side of the second supporting ring 801 is rotatably connected with the second gear ring 802; the inner right part of the second gear ring 802 is welded with the third linkage frame 803; the third linkage frame 803 is fixedly connected with a plurality of second sprinkler heads 804 ; The upper part of the second support frame 601 on the right side is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com