Method and device for producing plastic preforms and plastic containers with hot preform reservoirs

A technology for plastic preforms, plastic containers, applied in the field of production and equipment for plastic preforms and plastic containers with thermal preform storage, able to solve the problem of exceeding the process limits, impossible to guarantee the preform inlet temperature Issues such as preform energy content, processing window loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

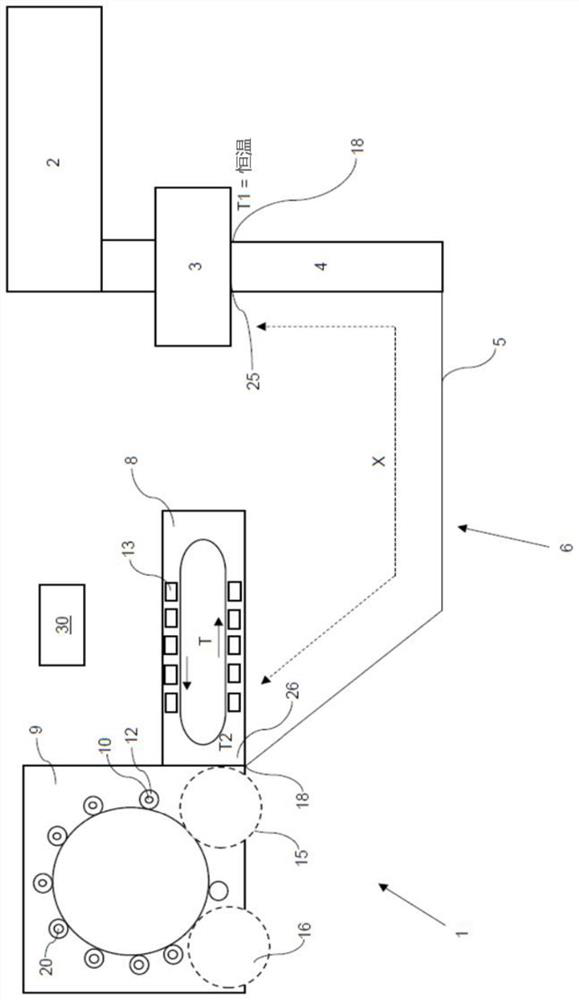

[0054] figure 1 A schematic diagram of the apparatus 1 producing the plastic preform 10 and the plastic container 20 according to the present invention is shown. Reference numeral 2 refers to an injection molding machine producing a plastic preform 10. After production, the plastic preform is transferred to the thermal preform reservoir 3 and maintains a constant temperature T1 here, which corresponds to the temperature of the plastic preform from the injection molding machine 2.

[0055] For example, if the subsequent machine has been downtime, the plastic preform can preferably prevent further delivery of the outlet 25 of the thermal preform storage 3 by the blocking device 18. Otherwise, the plastic preform is passed through the preform reservoir 3 in a predetermined time, and then into the sorting device 4, the sorting device 4 is sorted in a predetermined manner, in particular, in the same manner. Before the plastic preform is fed to the heating device 8 along the conveying ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap