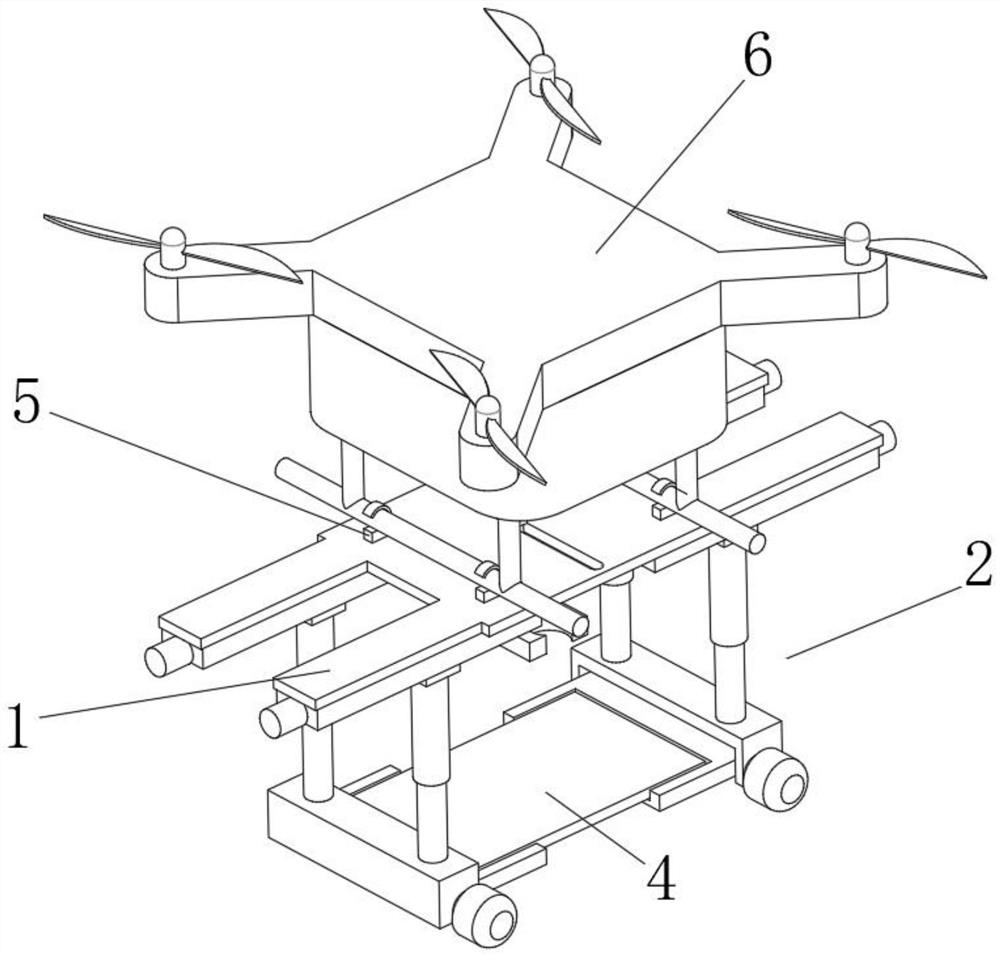

Suspension type unmanned aerial vehicle carrying device

A suspension and suspension technology, which is applied in the field of suspended UAV loading devices, can solve the problems of UAV shaking and instability, difficult and cumbersome unloading, accidental falling, etc. Safety, Enhanced Adaptability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

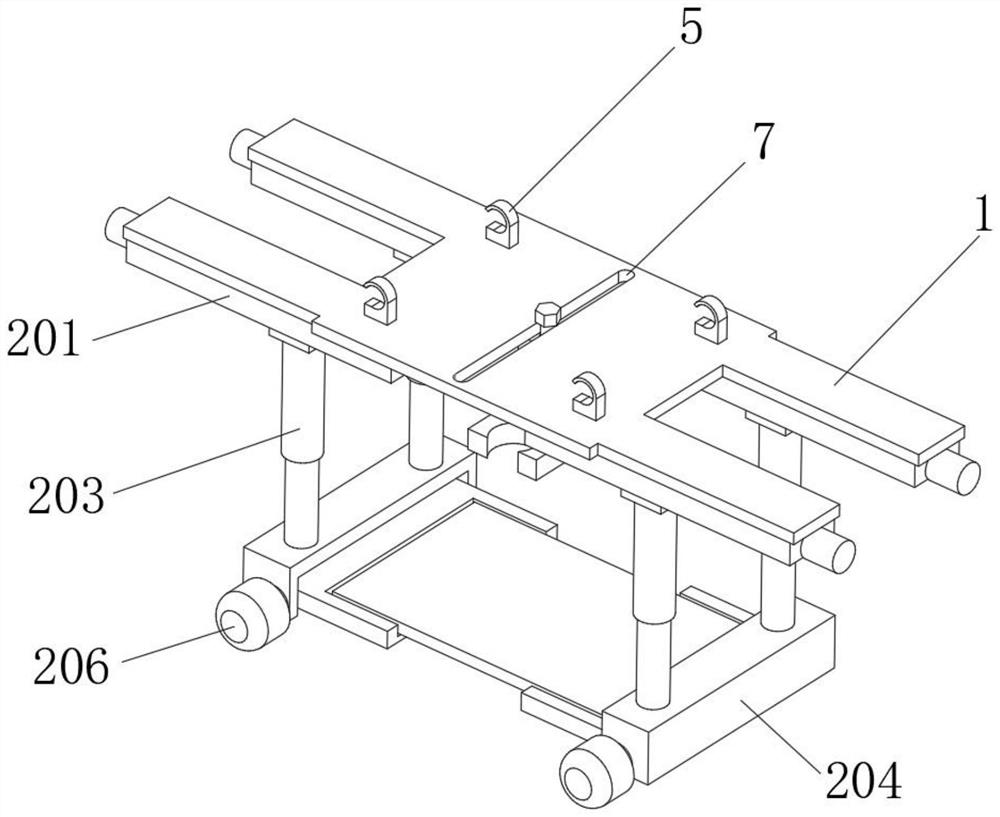

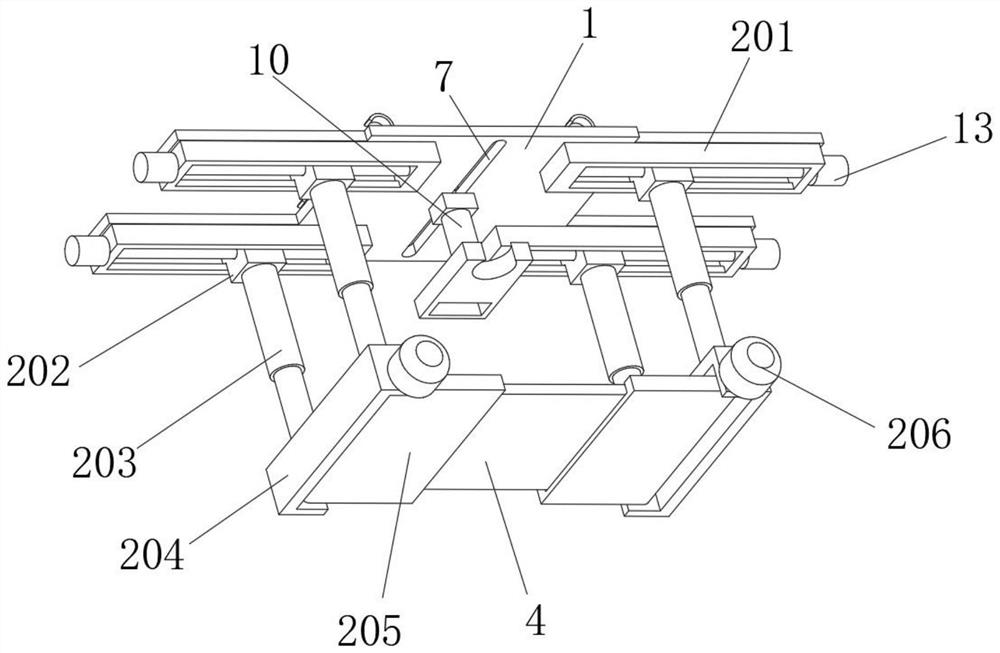

[0027] see Figure 1-4 , in the embodiment of the present invention, the rotary unloading mechanism 2 includes a carriage 201 fixedly installed at the bottom end of the suspension support plate 1, the inside of the carriage 201 is slidably connected with a slider 202, and the outside of the carriage 201 is fixedly installed with a drive socket The ball screw inside the slider 202 rotates the second motor 13, the bottom end of the slider 202 is fixedly equipped with a first hydraulic rod 203, and the bottom end of the first hydraulic rod 203 is fixedly installed with a support seat 204, and the support seat 204 The inside of the support plate 205 is connected with the support plate 205 through the rotation of the rotating shaft. The first motor 206 that drives the support plate 205 to rotate is fixedly installed on the outside of the support seat 204. The inside of the support plate 205 is provided with a groove 3, and the inside of the groove 3 is flexibly connected The connec...

Embodiment 2

[0029] see Figure 4-5 , the inside of the suspension support plate 1 is provided with a chute 7, the inside of the chute 7 is slidingly connected to the limit fixing bolt 8, the bottom end of the limit fixing bolt 8 is threadedly connected with the adjustment block 9, and the bottom end of the adjustment block 9 is fixedly installed There is a second hydraulic rod 10, and the bottom end of the second hydraulic rod 10 is fixedly equipped with an extruding plate 11, and the inside of the extruding plate 11 is provided with different shapes of limiting grooves 12 for stabilizing the sharp part of the top of the article. The groove 7 can control the adjustment block 9 to move and rotate horizontally, and the adjustment block 9 can drive the extrusion plate 11 to adjust the position, so as to ensure that the extrusion plate 11 can fall stably to squeeze and fix the article. By setting the second hydraulic rod 10, It can control the lifting of the extrusion plate 11, so that the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com