Movable multi-track fork and working method thereof

A multi-track and turnout technology, applied in the field of subway tunnel construction, can solve the problems of dismantling and splicing the track for a long time, affecting construction efficiency and construction progress, and taking a long time to reach the working face, etc., achieving significant social and economic benefits , shorten the excavation period and save construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

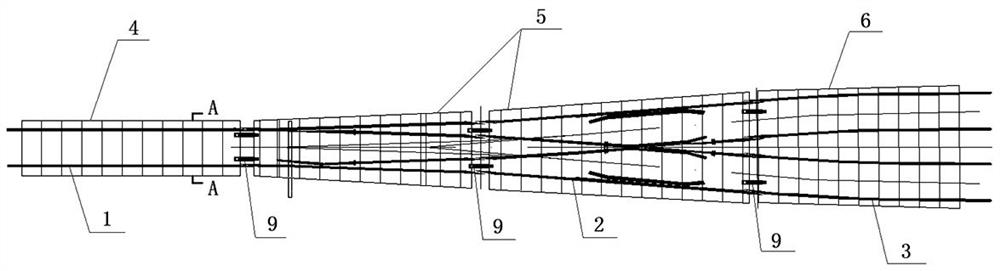

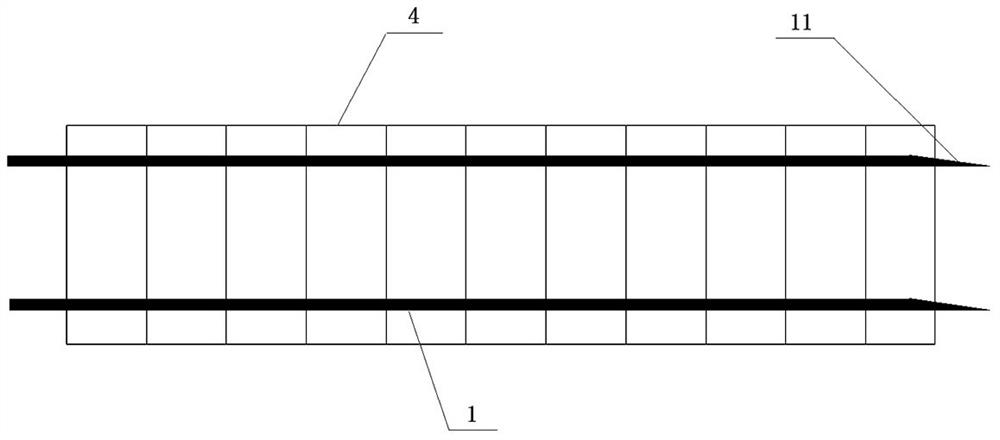

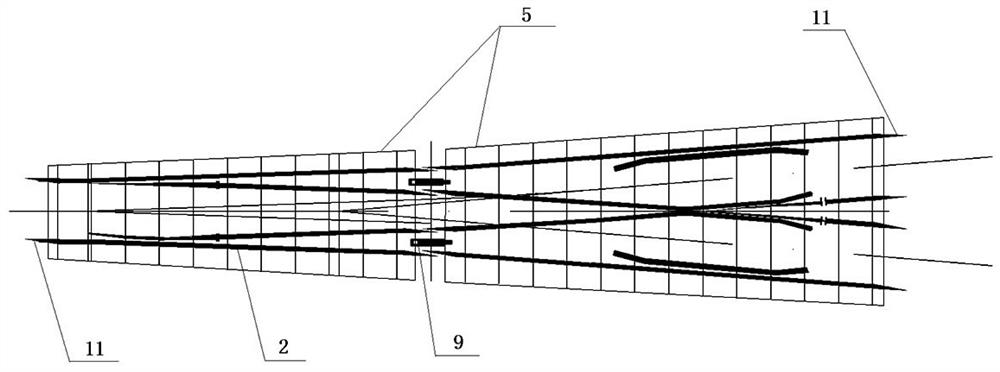

[0027] Example: such as Figure 1-8 As shown, this embodiment relates to a movable multi-track turnout, which mainly includes a front-end guide rail 1, a turnout 2, and a rear-end guide rail 3 arranged in sequence. The front-end guide rail 1 is fixed on the first wear-resistant steel plate 4 through a spring clip, and the turnout 2 is fixed on the second wear-resistant steel plate 5 by a spring clamp, the rear guide rail 3 is fixed on the third wear-resistant steel plate 6 by a spring clamp, and the first wear-resistant steel plate 4, the second wear-resistant steel plate 5 and the third wear-resistant steel plate 6 are all installed on the tunnel track 7. Among them, the turnout 2 is designed in sections, and is formed by the first turnout assembly and the second turnout assembly. The first turnout assembly and the second turnout assembly are installed on two second wear-resistant steel plates 5 respectively; The end guide rail and the second rear end guide rail, the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com