Rectangular or similar-rectangular ultra-large-section underground space construction method and construction system

A technology for underground space and construction methods, applied in underground chambers, earth drilling, mining equipment, etc., can solve problems such as high construction risk, high difficulty in excavation, and high difficulty in manufacturing, so as to improve economic benefits and reduce construction difficulty and risk, reducing the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: A kind of construction method of large section underground space, comprises the following steps:

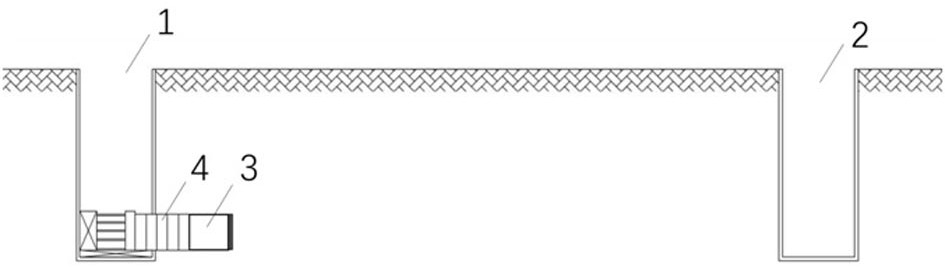

[0040] S1. Construction preparation: if figure 1As shown, according to the area of underground space to be built, symmetrical originating shaft 1 and receiving shaft 2 are built at appropriate positions on the construction site. Requirements for pipe section 4.

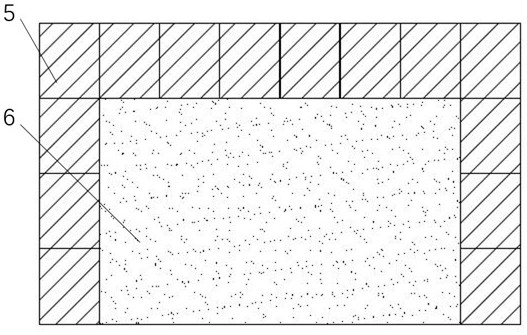

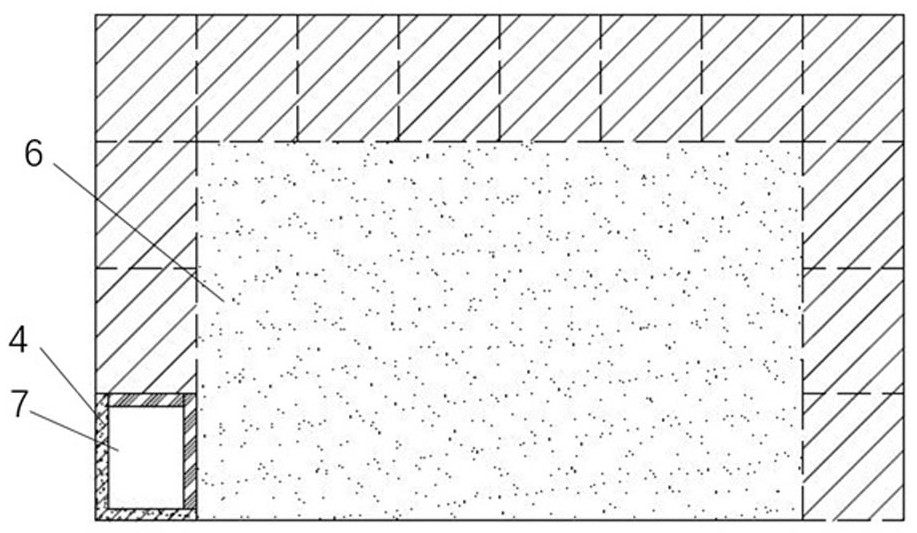

[0041] S2. Jacking area planning: such as figure 2 As shown, the underground construction space area is first divided into the central excavation area 6, and the periphery of the central excavation area 6 is divided into U-shaped subdivision excavation areas, and the central excavation area 6 is divided into one-to-one correspondence with the subdivision excavation areas, and then Divide the partial excavation area into several jacking units 5. The jacking units are divided according to engineering conditions and reasonably determined modulus. The section size of each jacking unit matches the ex...

Embodiment 2

[0048] Embodiment 2: a kind of construction method of large-section underground space, such as Figure 9 and Figure 10 As shown, in the step S2, the underground construction space area is firstly divided into two groups of jacking units 5, the overall shape of the two groups of jacking sections is a mountain shape, and a group of central excavation areas are respectively divided into the inner sides of the two groups of jacking sections. In the embodiment, the section of the jacking unit is preferably 5m wide and 5m high; as Figure 11 As shown, the jacking device is used to symmetrically jack up synchronously or step by step along both sides of the planned jacking section, assemble the combined pipe joint 4, complete the reception of the rectangular roadheader in the receiving shaft 2, and complete the construction of a jacking unit. Excavation and support construction, and complete the excavation and support construction of the remaining jacking units in sequence; then rem...

Embodiment 3

[0050] Embodiment 3: A construction system for a rectangular or quasi-rectangular super-large-section underground space, including a central excavation area and subdivision excavation areas, the subdivision excavation areas are located on the periphery of the central excavation area, and subdivision excavation areas are provided with Several jacking units, the jacking unit is assembled with a combined pipe joint, and the adjacent combined pipe joints are connected and assembled in sequence in the partial excavation area to form a pipe joint support structure as a whole, and a waterproof structural unit is laid in the jacking unit , the adjacent waterproof structural units are successively laid in the subdivision excavation area to form a waterproof structure as a whole, the outer peripheral main structural unit is laid in the jacking unit, and the adjacent outer peripheral main structural units are laid in turn in the subdivision area to form a subdivision area as a whole The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com