Construction Method of Upside-Down Shaft Wall in Open-cut Trench in Central Area of City

A construction method and technology of hanging well wall upside down, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high soil covering requirements for construction structures, easy damage to underground pipelines, low efficiency, etc., and reduce solid waste. The effect of production volume, solving the shortage of construction space and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

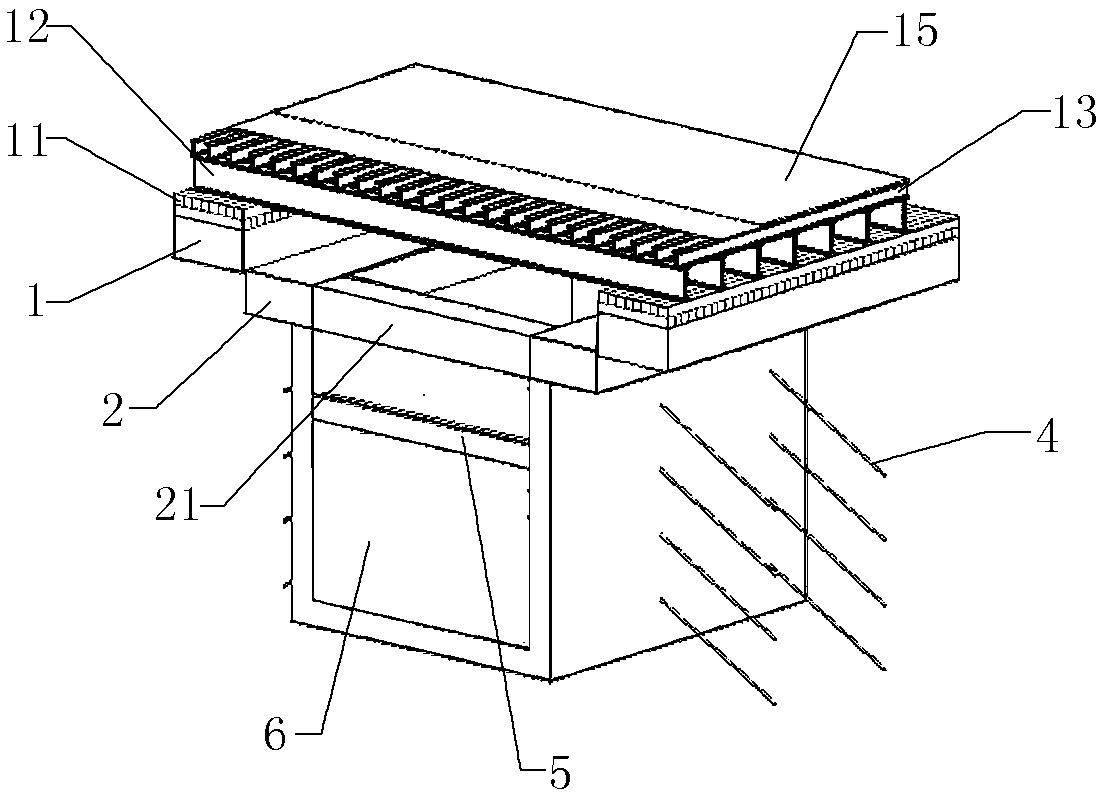

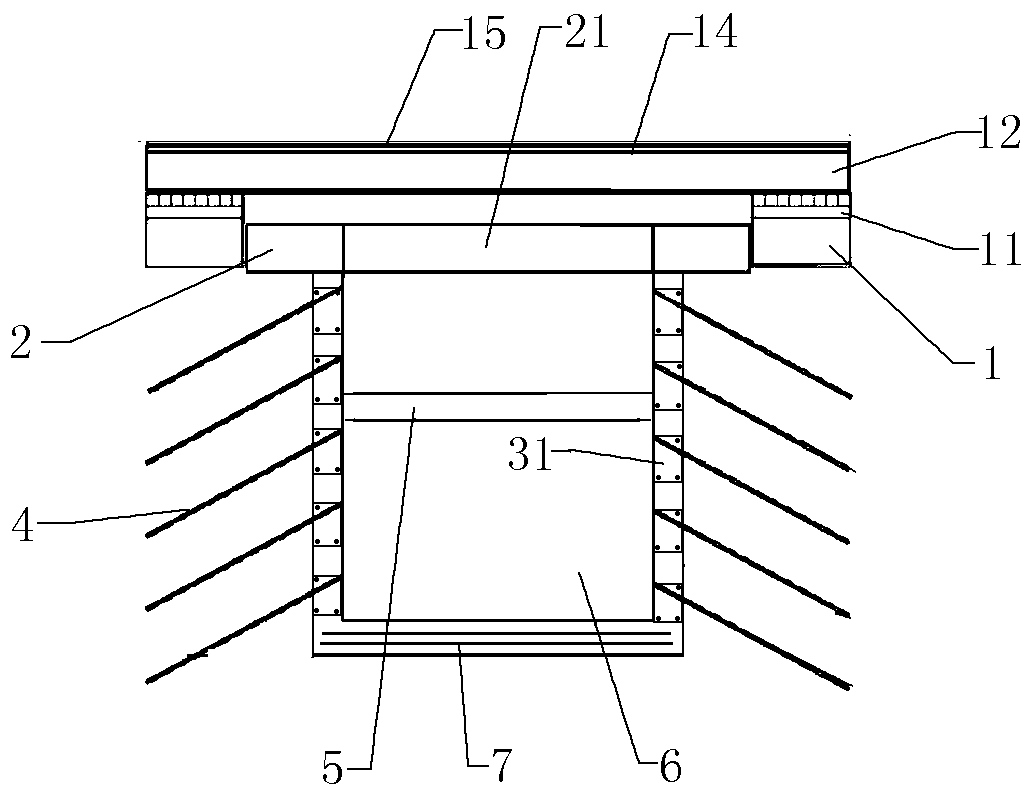

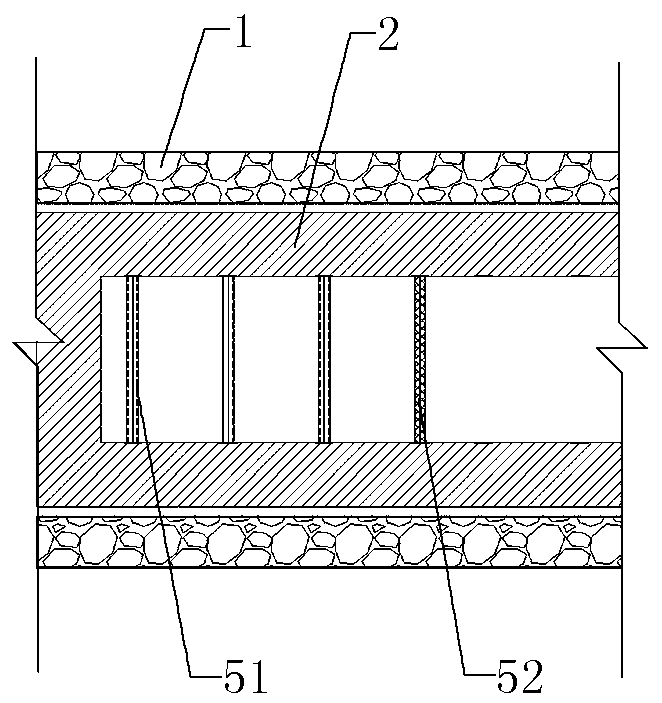

[0062] Such as Figure 1-Figure 7 Shown, the upside-down shaft wall construction method of open-cut trenches in the urban central area of the present invention comprises the following steps:

[0063] Step 1, steel temporary bridge construction: set steel temporary bridge foundations 1 on the outside of the edge of the groove 6 to be constructed, and then span support beams at intervals on the steel temporary bridge foundation 1, and lay shock-absorbing rubber 14 and steel plates 15 sequentially on the support beams; The steel temporary bridge foundation 1 is a C30 concrete structure; the width of the steel temporary bridge foundation 1 is not less than 1m;

[0064] The specific construction method of the steel temporary bridge includes the following steps:

[0065] Step a, foundation pouring of the steel temporary bridge: Excavate the grooves of the steel temporary bridge foundation 1 on both sides of the trench 6 to be constructed, and pour C30 concrete to form the steel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com