Rapid erecting system and method for ultra-long modular floating breakwater

A floating breakwater and modular technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve the problems of reduced transportation efficiency inside the cabin, failure to achieve fast installation, and occupying the space of the hull, so as to avoid the yaw of the installation axis and lift the installation The effect of improving speed and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

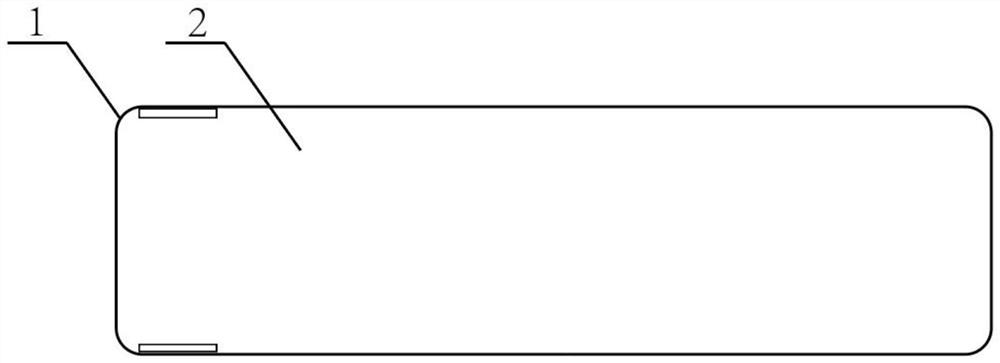

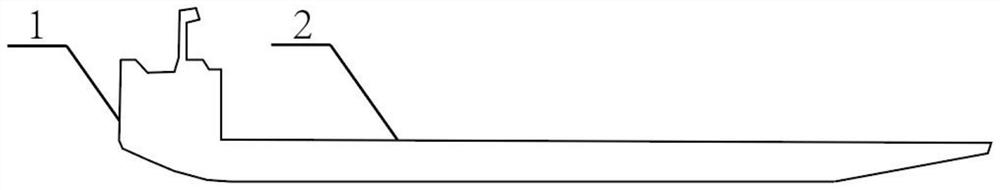

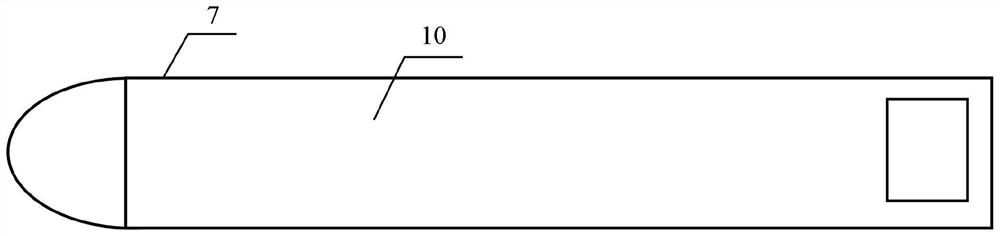

[0068] figure 1 It is a schematic diagram of the top view structure of the mother ship 1 in the present invention, figure 2 It is a schematic diagram of the front view structure of the mother ship 1 in the present invention, image 3 It is a schematic diagram of the top view structure of the neutron ship 7 of the present invention, Figure 4 It is a schematic structural diagram of the front view of the neutron ship 7 of the present invention, Figure 5 It is a top view of the loading structure of the floating breakwater unit 3 on the mother ship 1 in the present invention, Image 6 It is a front view of the loading structure of the floating breakwater unit 3 on the mother ship 1 in the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 An ultra-long modular floating breakwater rapid erection system is shown, including a mother ship 1, a sub-ship 7, an auxiliary tugboat 11, a floating breakwater, an anchor cable system 5 and...

Embodiment 2

[0070] Figure 7 It is a top view of the loading structure of the anchor block 8 on the sub-ship 7 in the present invention, Figure 8 It is the front view of the loading structure of the anchorage block 8 on the sub-ship 7 in the present invention, as Figure 7 and Figure 8 An anchorage block 8 of an ultra-long modular floating breakwater rapid erection system is shown. The anchorage block 8 sinks on the seabed to provide anchorage force for the floating breakwater system. Gravity anchors or rocket anchors are used. Sufficient anchoring force, the present invention connects a floating ball C26 through a rope 23 on each anchoring block 8, and the main function of the floating ball C26 is to display the water level of the anchoring block 8 after the floating breakwater system is installed. next position.

Embodiment 3

[0072] Figure 16 It is the structural representation of universal wheel bracket A6 among the present invention, Figure 17 It is the structural representation of universal wheel bracket B9 among the present invention, Figure 18 It is a schematic diagram of the anchorage block structure in the present invention, such as Figure 16 , Figure 17 and Figure 18 The shown universal wheel 14 bracket structure of a super-long modular floating breakwater rapid erection system includes universal wheel bracket A6 and universal wheel bracket B9, and the first universal wheel bracket A6 is a bottom belt The flat structure of a plurality of universal wheels 14, including the loading platform A13 and the universal wheels 14, the universal wheels 14 can roll in a 360-degree direction, and can be locked and unlocked as required. The loading platform A13 is a rectangular structure, and the floating The bottom plate of the breakwater unit 3 has the same width and the area is close to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com