Oilfield high-pressure water injection pump disc moving device and using method

A disc drive device and water injection pump technology, which is applied to components, pumps, piston pumps, etc. of pumping devices for elastic fluids, can solve the problems of disc pump inconvenience, easily damaged tools, and damaged equipment finish, and achieve disc The effect of fast pump speed, increased water injection capacity, and improved operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

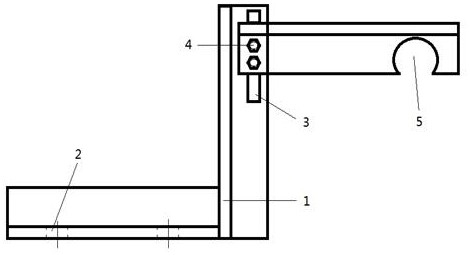

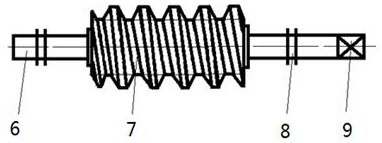

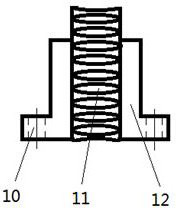

[0044] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0045] A high-pressure water injection pump disc drive device in an oil field, including a fixing device, a worm gear mechanism, and a booster drive mechanism;

[0046] The worm gear mechanism is fixed on the fixing device, the power input end of the worm gear mechanism is connected to the power output end of the booster drive mechanism, and the power output end of the worm gear mechanism is connected to the pump shaft of the water injection pump.

[0047] Further, the fixing device includes a worm fixing seat and a worm wheel fixing seat;

[0048] There are two worm fixing seats, which are symmetrically installed on both sides of the water injection pump bearing seat respectively. The worm gear mechanism is composed of a worm wheel 11 and a worm 7 that are meshed with each other, wherein a worm snap ring 8 is arranged on the transmission shaft in the center of the worm, and the worm Co...

Embodiment 2

[0065] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0066] A high-pressure water injection pump disc drive device in an oil field, including a fixing device, a worm gear mechanism, and a booster drive mechanism;

[0067] The worm gear mechanism is fixed on the fixing device, the power input end of the worm gear mechanism is connected to the power output end of the booster drive mechanism, and the power output end of the worm gear mechanism is connected to the pump shaft of the water injection pump.

[0068] Further, the fixing device includes a worm fixing seat and a worm wheel fixing seat;

[0069] There are two worm fixing seats, which are symmetrically installed on both sides of the water injection pump bearing seat respectively. The worm gear mechanism is composed of a worm wheel 11 and a worm 7 that are meshed with each other, wherein a worm snap ring 8 is arranged on the transmission shaft in the center of the worm, and the worm Co...

Embodiment 3

[0079] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0080] A high-pressure water injection pump disc drive device in an oil field, including a fixing device, a worm gear mechanism, and a booster drive mechanism;

[0081] The worm gear mechanism is fixed on the fixing device, the power input end of the worm gear mechanism is connected to the power output end of the booster drive mechanism, and the power output end of the worm gear mechanism is connected to the pump shaft of the water injection pump.

[0082] Further, the fixing device includes a worm fixing seat and a worm wheel fixing seat;

[0083] There are two worm fixing seats, which are symmetrically installed on both sides of the water injection pump bearing seat respectively. The worm gear mechanism is composed of a worm wheel 11 and a worm 7 that are meshed with each other, wherein a worm snap ring 8 is arranged on the transmission shaft in the center of the worm, and the worm Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com