Control type magnetic suspension vibration isolation platform

A technology of vibration isolation platform and magnetic levitation, which is applied in the direction of vibration suppression adjustment, magnetic attraction or thrust holding device, electrical components, etc. It can solve the problems of reducing the practicality of the device, troublesome operation, troublesome installation and disassembly, etc., and achieve the practical effect of improvement , good anti-slip effect, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

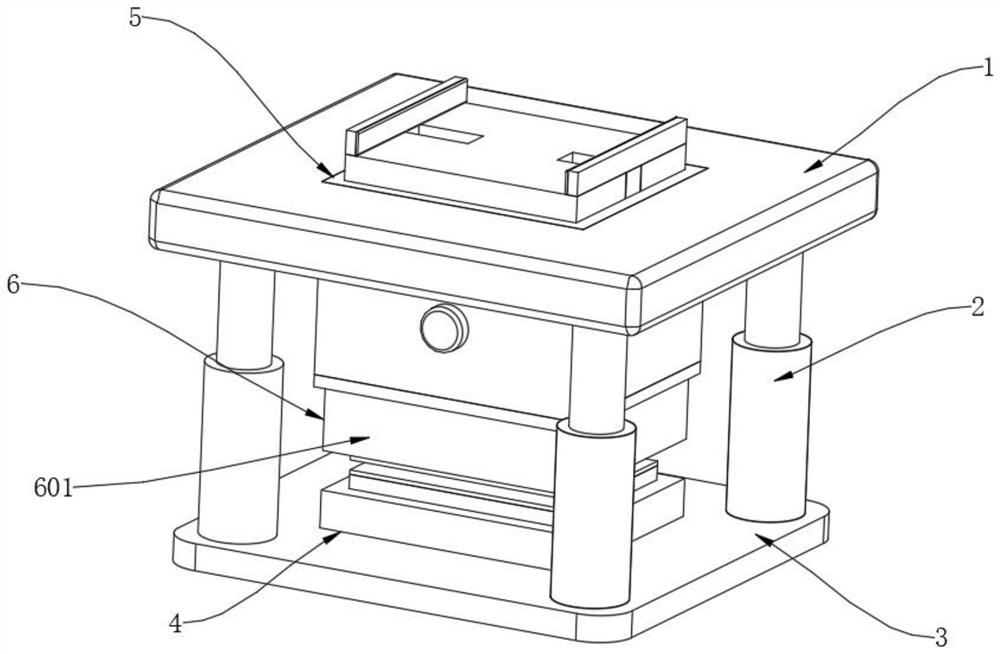

[0032] Example: such as Figure 1-8As shown, the present invention provides a control-type magnetic suspension vibration isolation platform, including a vibration isolation workbench 1, a group of buffer brackets 2 are fixedly connected to the lower end surface of the vibration isolation workbench 1, and the buffer brackets 2 are diagonally distributed to play the role of Good shock absorption effect, the lower end surface of the buffer bracket 2 is fixedly connected with the vibration isolation platform base 3, the center position of the upper end surface of the vibration isolation platform base 3 is provided with a magnet installation mechanism 4, and the center position of the vibration isolation workbench 1 is provided with The equipment fixing mechanism 5 is provided with a magnetic levitation control box 6 below the equipment fixing mechanism 5 .

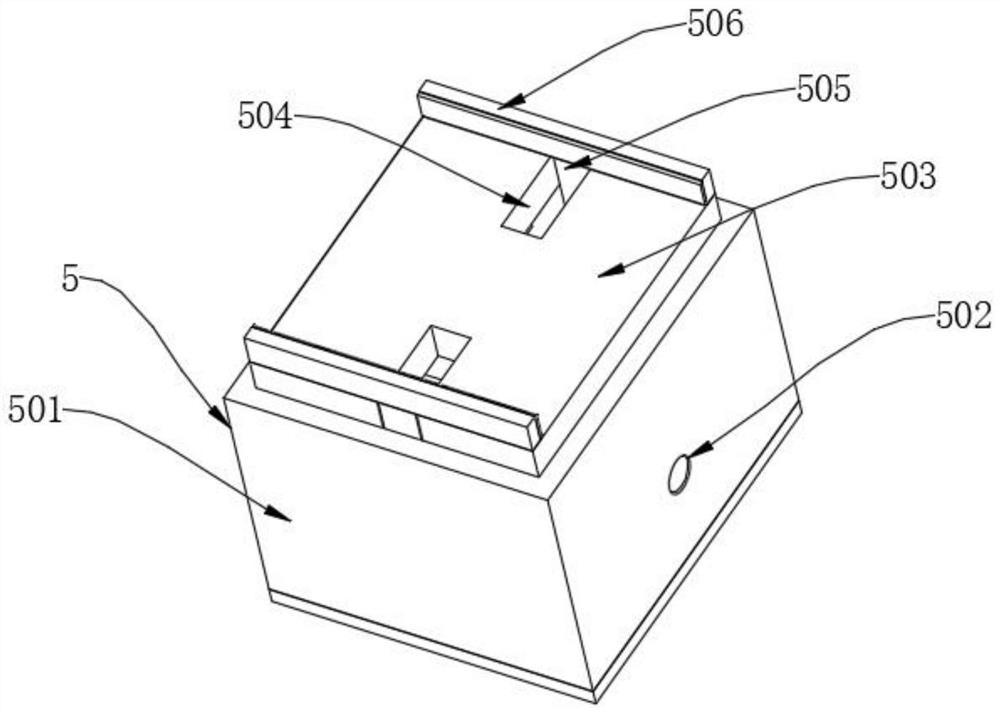

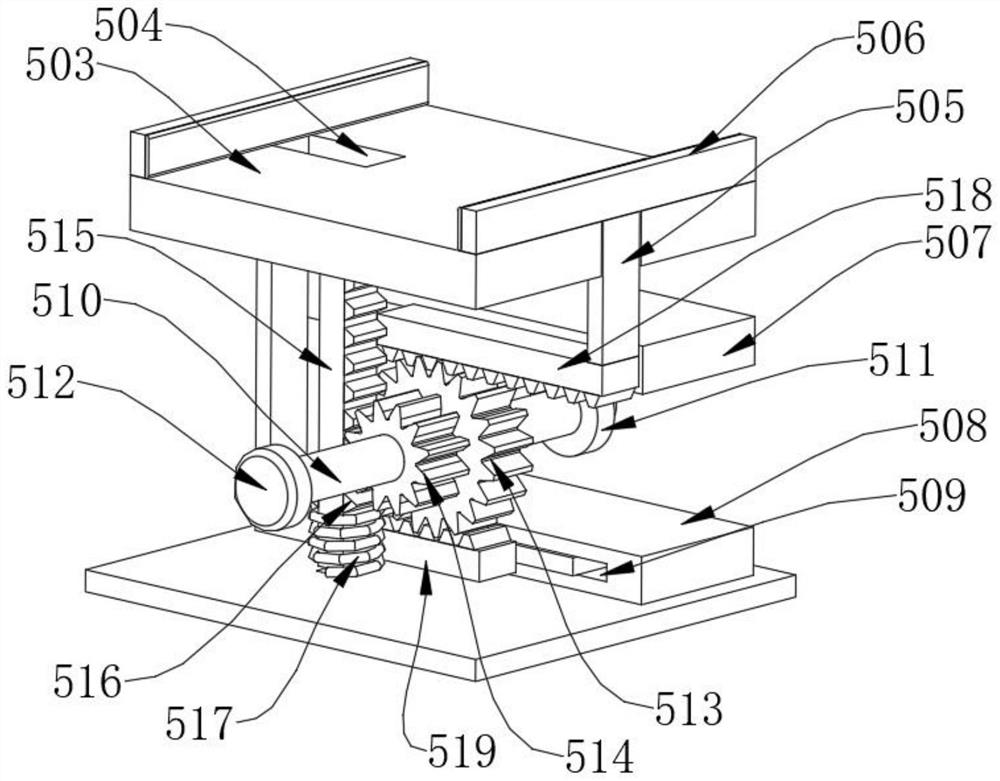

[0033] Further, the equipment fixing mechanism 5 includes a sealing frame 501 located at the inner center of the vibration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com