Full-band spectrometer and working method thereof

A working method and full-band technology, applied in the field of spectrometers, can solve the problems of high product failure rate, high production cost, difficult to meet the requirements of precision, etc., and achieve the effect of good elimination effect, simple debugging and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

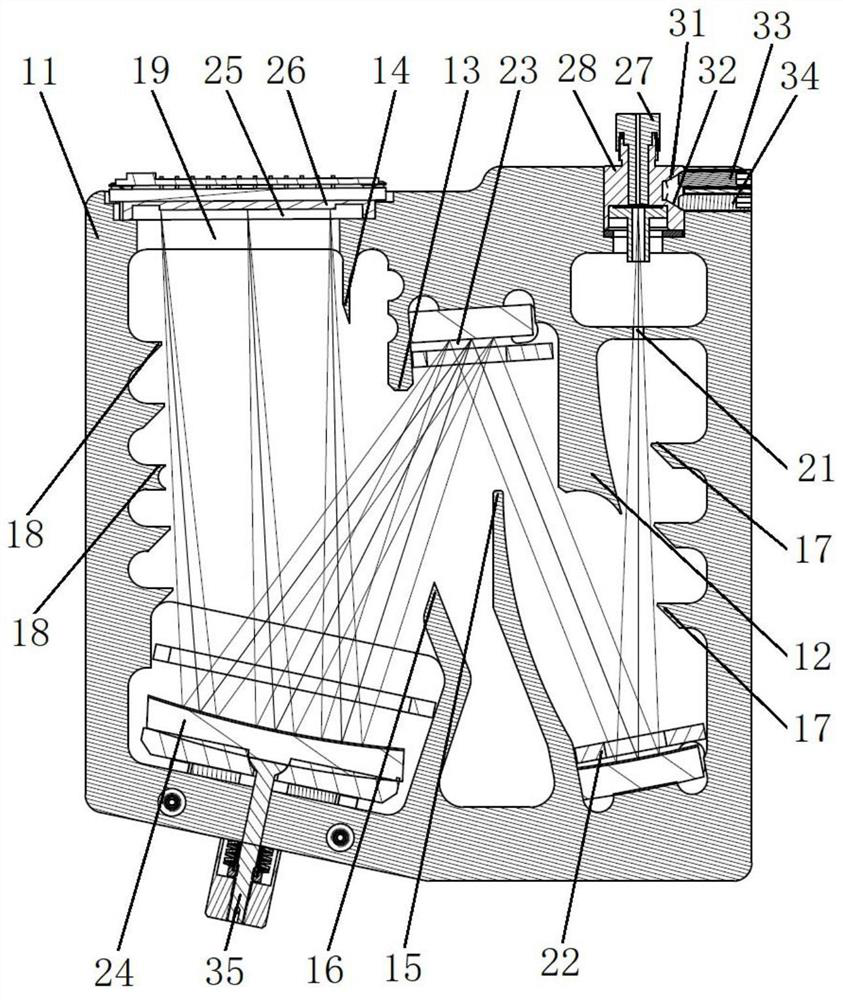

[0033] figure 1 A schematic structural diagram of the full-band spectrometer of the embodiment of the present invention is given, as figure 1 As shown, the full-band spectrometer includes:

[0034] Housing 11, collimating mirror 22, grating 23, imaging mirror 24 and array detector 26, the collimating mirror 22, grating 23 and imaging mirror 24 are arranged inside the housing 11, and array detector 26 is arranged On the outside of the housing 11; the measurement light is imaged on the array detector 26 after passing through the collimating mirror 22, the grating 23 and the imaging mirror 24 in sequence;

[0035] An optical fiber head 27 and an optical fiber holder 28, the optical fiber head 27 is fixed on the optical fiber holder 28, the optical fiber holder 28 is arranged on the housing 11; the optical fiber is plugged into the optical fiber head 27;

[0036] A first adjustment unit, the first adjustment unit is used to adjust the distance between the fiber holder 28 and the...

Embodiment 2

[0062] An application example of the full-band spectrometer and its working method in multi-component gas measurement according to Embodiment 1 of the present invention.

[0063] In this application example, as figure 1 As shown, the outline of the housing 11 is substantially rectangular, including a first side wall, a second side wall, a third side wall and a fourth side wall connected in sequence; the first side wall has a cylindrical channel; the optical fiber head 27 is fixed on On the cylindrical fiber seat 28, the central axis of the fiber head 27, the central axis of the fiber seat 28, and the central axis of the cylindrical channel all coincide; the optical fiber seat 28 is arranged in the cylindrical channel, along the The central axis moves positively and reversely. During the movement, the fiber seat 28 has no displacement in the direction perpendicular to the central axis of the channel; the side of the fiber seat 28 has a V-shaped groove, which is parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com