Prefabricated column sleeve grouting nondestructive testing method based on elastic wave and machine learning

A technology of machine learning and sleeve grouting, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as difficult practical application, difficulty in fullness detection, and high detection cost, so as to improve detection accuracy and efficiency and simplify the detection process Clear and analyze the effect of multiple parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

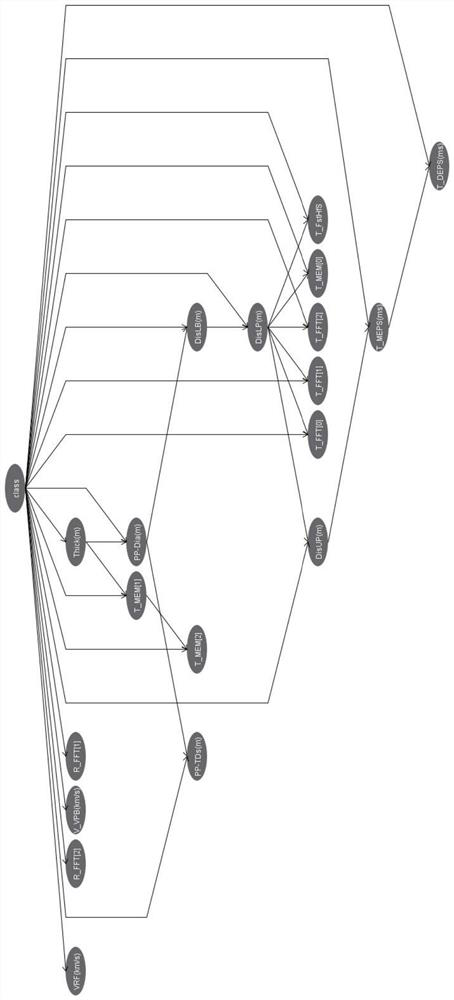

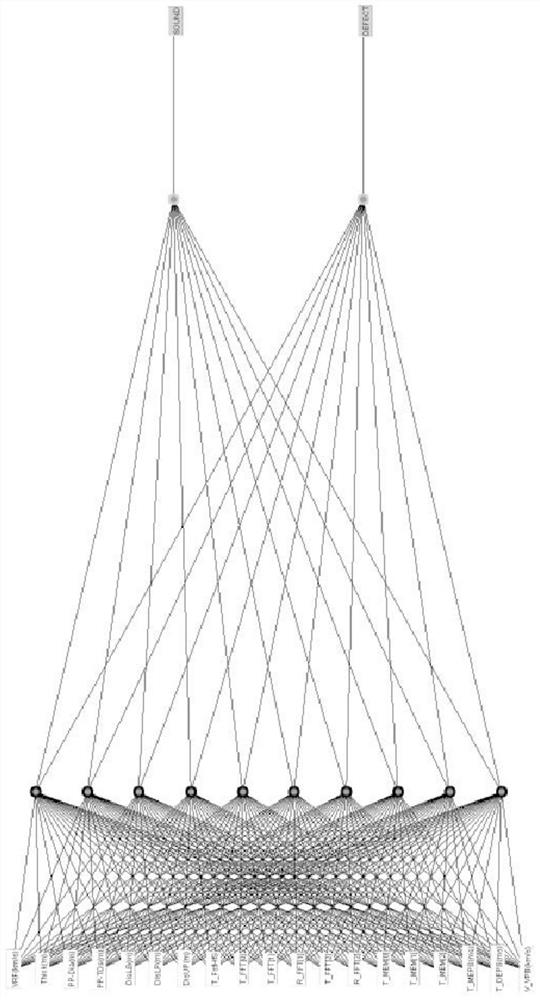

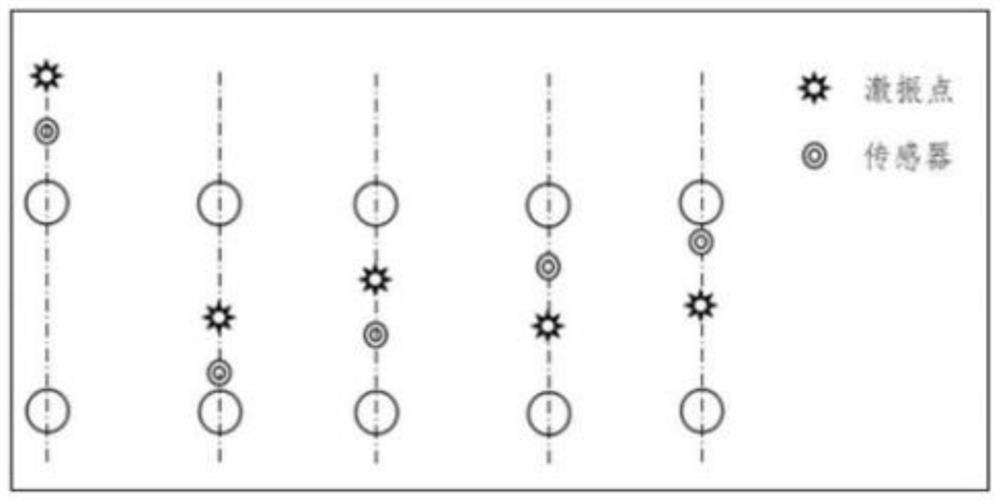

[0066] The non-destructive testing method for prefabricated column sleeve grouting based on elastic wave and machine learning mainly includes the following steps:

[0067] A. Shock elastic wave is used as the detection medium, and the analysis model is obtained by using the picked-up signal characteristics combined with machine learning, and then the grouting density of the sleeve is detected;

[0068] B. Signal features mainly use spectral characteristics and establish attributes for machine learning;

[0069] C. For each prefabricated column, obtain the information of the healthy part as the benchmark parameter reflecting the mechanical properties of the concrete;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com