Automatic monitoring device and method for self-repairing condition of overlying strata mining-induced fissure

A self-repairing and fissure technology, applied in measuring devices, radiation intensity measurement, geophysical measurement, etc., can solve problems such as high equipment cost, damage to overlying rock, and difficult data processing, so as to reduce equipment investment, reduce labor costs, monitor large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

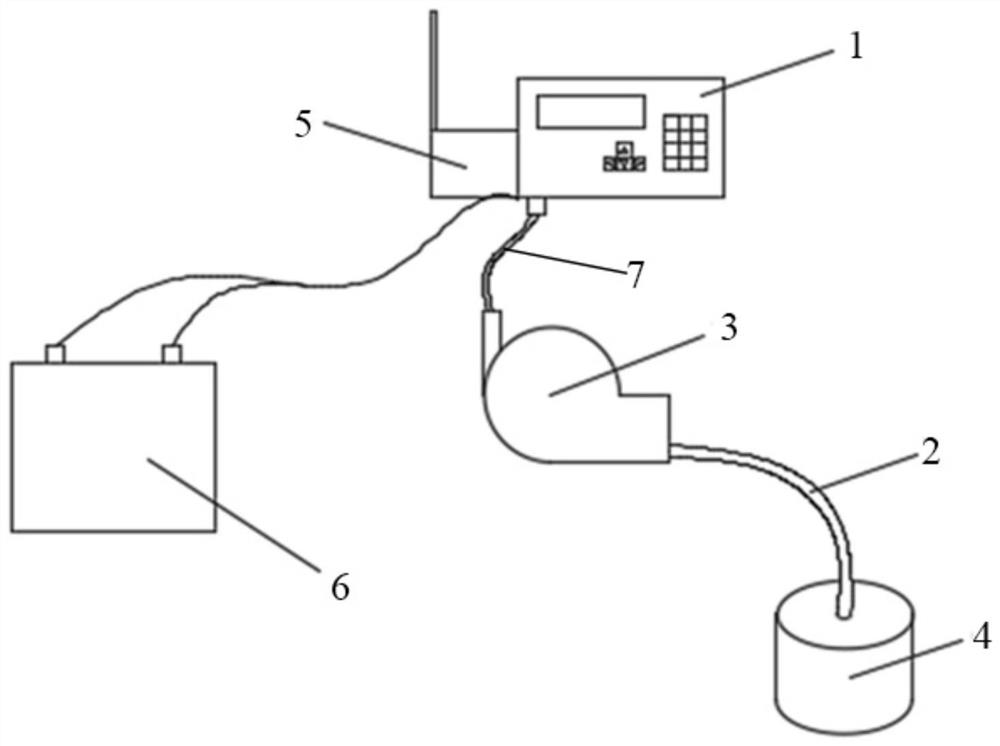

[0032] Such as figure 1 As shown, the present invention provides an automatic monitoring device for the self-repairing condition of overlying rock mining fissures. The monitoring device of the present invention comprises a radon measuring instrument 1, an electric air pump 3 and a plurality of air extractors 4, and the electric air pump 3 is provided with an air outlet and a plurality of openable and closable air inlets, and the air outlet is connected with the air inlets. The gas sampling port of the radon measuring instrument 1 is sealed and communicated, and each of the air inlets is sealed and connected with the corresponding gas extraction device 4 respectively, and the gas extraction device 4 is buried in a plurality of radon gas measuring points arranged on the detection area respectively. place.

[0033] Among them, the radon measuring instrument 1 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com