Method and device for testing direct current internal resistance of battery, electronic equipment and storage medium

A technology of DC internal resistance and testing method, which is applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as inaccurate DC internal resistance, and achieve the effects of wide application range, stable test results, and strong consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

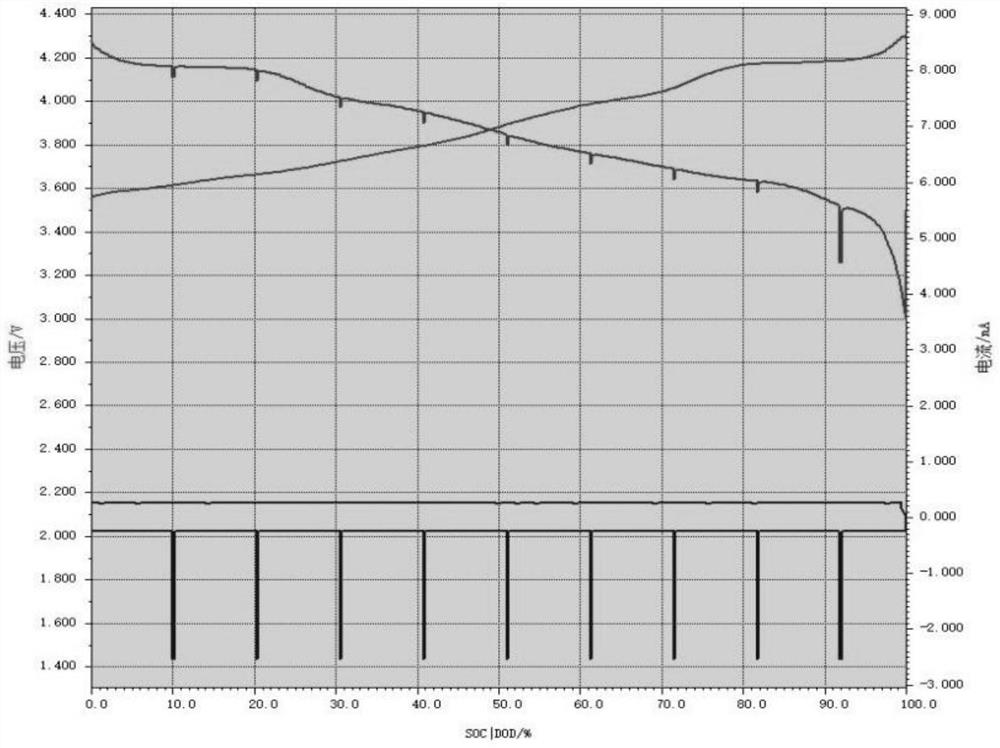

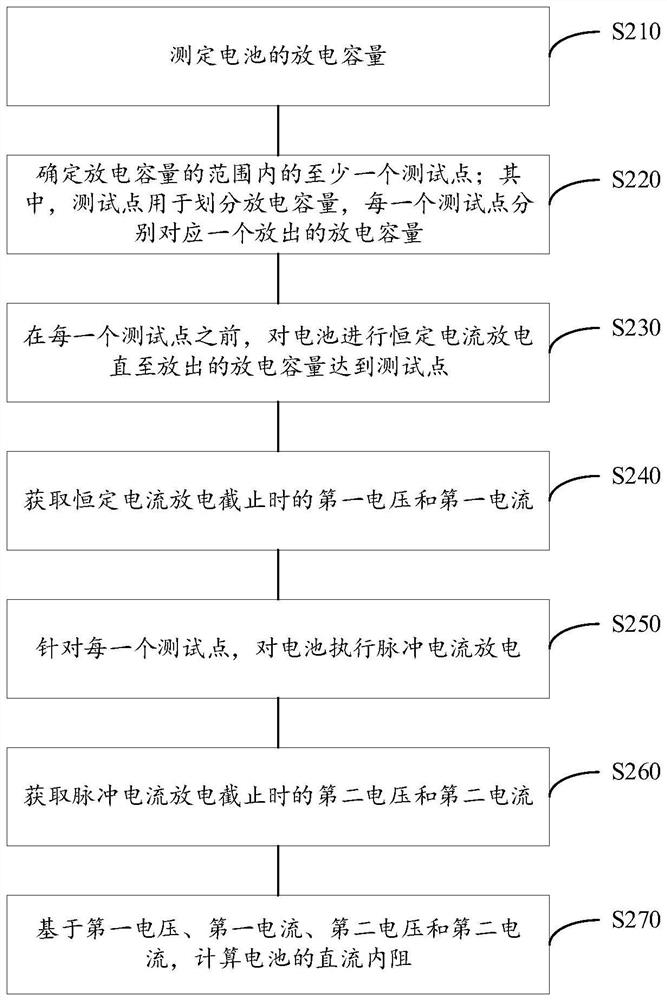

Method used

Image

Examples

preparation example Construction

[0076] 2) Preparation of positive electrode sheet

[0077] a. Weighing: the positive electrode active material, the conductive agent and the positive electrode binder are weighed according to the mass fraction between them: 80-97%: 1-10%: 2-10%; The content is 40%-65%, and the homogenized slurry includes positive electrode active material, conductive agent, positive electrode binder and positive electrode solvent. (The solid content refers to the mass fraction, where the solid content is the ratio of the sum of the mass of the positive electrode active material, the conductive agent, and the positive electrode binder to the sum of the mass of the positive electrode active material, the conductive agent, the positive electrode binder, and the positive electrode solvent. )

[0078] b. Homogenization: add the weighed conductive agent and positive electrode glue to the homogenizer, add the positive electrode solvent according to the designed solid content, and stir until complete...

Embodiment 1

[0131] 1. Preparation of positive electrode sheet

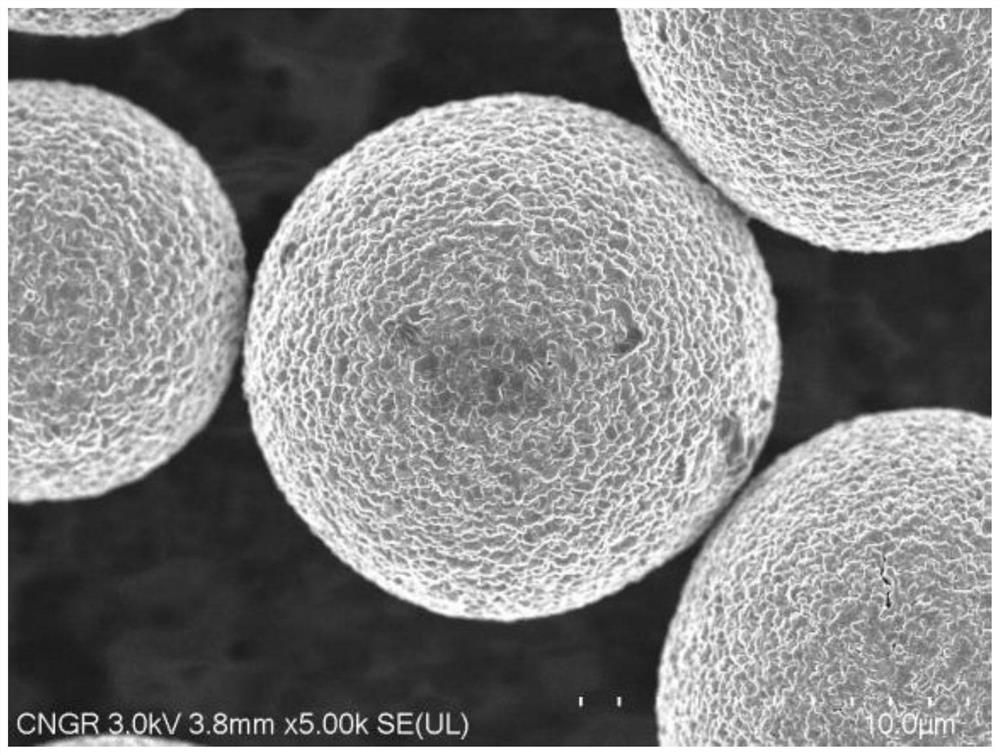

[0132] (1) Weighing: Weigh the positive active material (Li(Ni) 0.95 Co 0.03 Mn 0.02 )O 2 ) 9g, conductive graphite 0.5g, positive electrode glue 6.25g (composed of positive electrode solvent (NMP) and positive electrode binder (PVDF), of which PVDF mass fraction is 8%). Among them, the positive electrode active material is the positive electrode material, and the SEM image of the positive electrode material is as follows image 3 shown.

[0133] (2) Homogenization: add the weighed positive glue and conductive graphite to the homogenizer, add NMP according to the designed solid content of 50%, and stir until completely dissolved; then add the weighed Li (Ni) 0.95 Co 0.03 Mn 0.02 )O 2 , stir evenly, and complete the homogenization process.

[0134](3) Coating: The homogenized positive electrode slurry is evenly coated on the aluminum foil with a coating machine, and the coating thickness is 120 μm. After the coating i...

Embodiment 2

[0147] 1. Preparation of positive electrode sheet

[0148] (1) Weighing: Weigh the positive active material (Li(Ni) 0.65 Co 0.07 Mn 0.28 )O 2 ) 9.5g, conductive graphite 0.2g, positive electrode glue 3g (composed of positive electrode solvent (NMP) and positive electrode binder (PVDF), of which PVDF mass fraction is 10%). Among them, the positive electrode active material is the positive electrode material, and the SEM image of the positive electrode material is as follows Figure 5 shown.

[0149] (2) Homogenization: add the weighed positive glue and conductive graphite to the homogenizer, add NMP according to the designed solid content of 50%, and stir until completely dissolved; then add the weighed Li (Ni) 0.65 Co 0.07 Mn 0.28 )O 2 , stir evenly, and complete the homogenization process.

[0150] (3) Coating: The homogenized positive electrode slurry is evenly coated on the aluminum foil with a coating machine, and the coating thickness is 130 μm. After the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com