Color mixing device

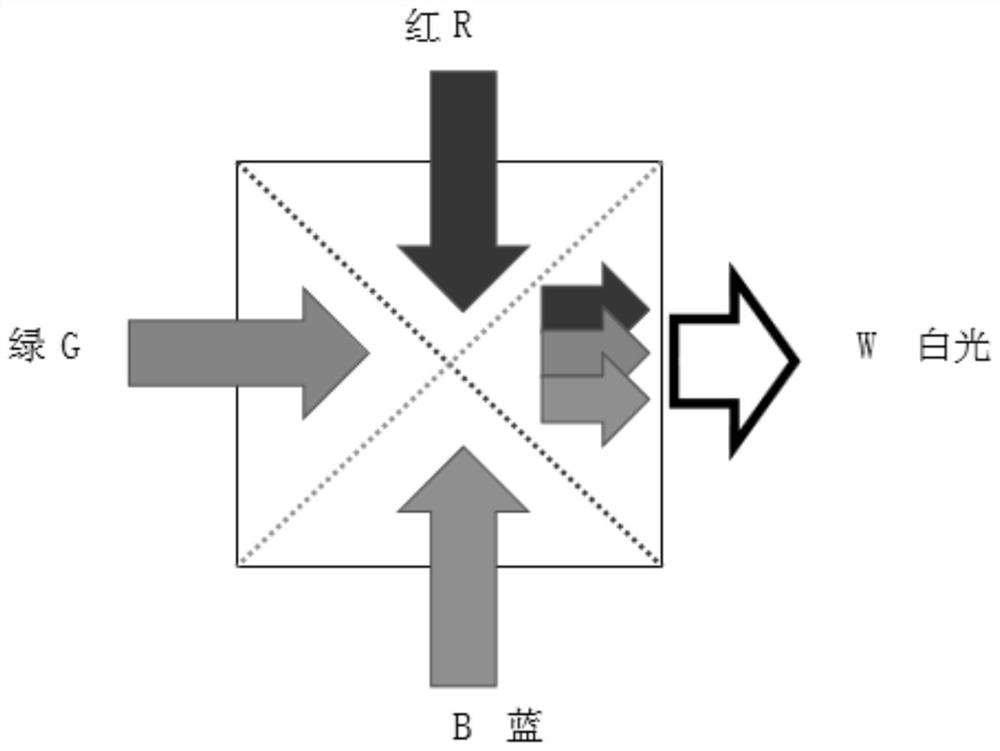

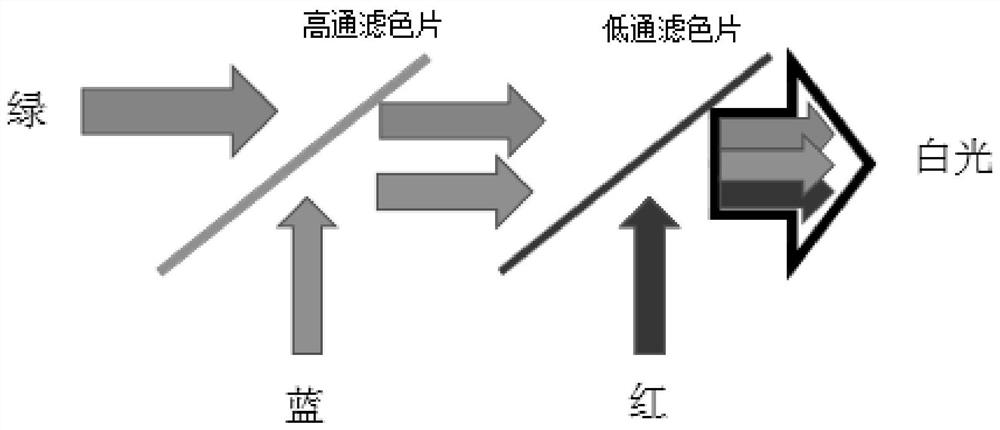

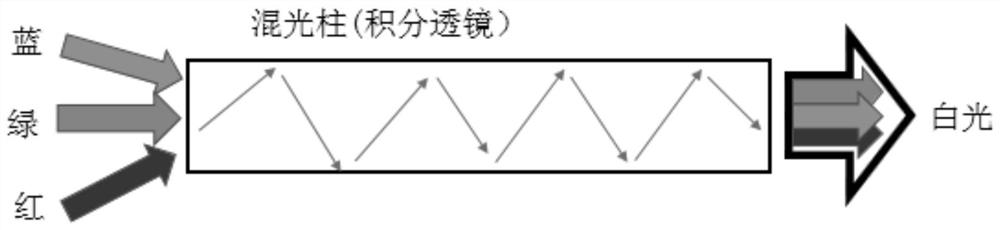

A color mixing and red technology, applied in the field of color mixing devices, can solve the problems of high production cost, increase the number of prisms, different optical paths, etc., and achieve the effects of low production cost, enhanced light-splitting ability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Please refer to Figure 5 to Figure 6 .

[0039] A color mixing device includes a light source module 10, an achromatic module 20, and a first color mixing module 30 arranged in sequence.

[0040] Wherein, the light source module 10 is used to provide light, which includes at least two monochromatic light sources with different wavelengths, and the monochromatic light sources are arranged on the focal plane 21 side of the achromatic module 20 .

[0041] In this embodiment, the light source module 10 includes a red light source 11, a green light source 12, and a blue light source 13. The red light source 11, the green light source 12, and the blue light source 13 are all LED light sources, and all have divergent light. Among them, the red light source 11 is used to provide red light, the green light source 12 is used to provide green light, and the blue light source 13 is used to provide blue light. 21 side of the focal plane.

[0042] The following rules exist in the...

Embodiment 2

[0053] Please refer to Figure 8 .

[0054] In order to further enhance the light combining ability of the color mixing device, the color mixing device further includes a second color mixing module 40, the second color mixing module 40 includes a second prism 41, the second prism 41 is also a triangular prism, and the second prism 41 has a second incident surface 42 and two second non-incident surfaces 43, each side of the second non-incidence surface 43 is provided with a second reflector 44, and there is a distance between the second non-incidence surface 43 and the second reflector 44;

[0055] The primary mixed light beam is refracted from the second incident surface 42 into the second prism 41, then refracted and exited by one of the second non-incident surfaces 43, and then reflected by the second reflector 44 at the corresponding position, and the reflected light passes through the second non-incident surface 43. Surface 43 is refracted into the second prism 41, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap