Method for calculating offset of neutral layer in thick plate bending forming process

A bending forming and calculation method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as shallow understanding of deformation and insufficient theoretical analysis, and achieve the effect of improving forming accuracy and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take JCO forming of thick plate as an example:

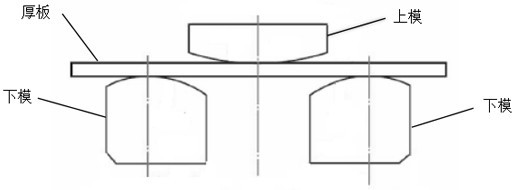

[0045] Such as Figure 1-2 As shown, a calculation method for the neutral layer offset in the thick plate JCO forming process includes the following steps:

[0046] Step 1: Obtain the linear distribution curve of the thickness strength by using the layered tensile fracture experiment, and establish the stress-strain mathematical model according to the thick plate bending theory:

[0047] (1)

[0048] K--hardening coefficient,

[0049] n--hardening index,

[0050] Q--a coefficient reflecting the degree of inhomogeneity in the thickness distribution of strength,

[0051] z--the vertical distance between the board layer and the middle layer,

[0052] e--Theoretical neutral layer offset,

[0053] t - the thickness of the thick plate,

[0054] E - modulus of elasticity;

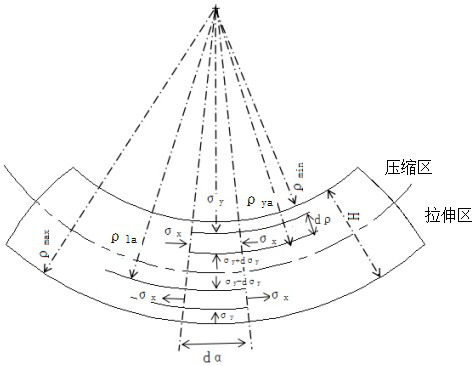

[0055] Step 2: Take micro-elements in the tension zone and compression zone respectively for force balance analysis, and obtain the neutral layer ...

Embodiment 2

[0075] In order to verify the present invention, the thick plate material is selected as nickel-based alloy as an example.

[0076] The basic parameters of the thick plate are: the width of the thick plate W =1000 mm , the length of the slab L =2000 mm , the thickness of the slab t =60 mm , Young's modulus E =205GPa, Poisson's ratio is 0.3, density is 7.82 g / cm 3 . The radius of curvature of the upper mold is 150 mm , the radius of curvature of the lower die is 150 mm , the span of the lower die is 770 mm . The upper and lower dies are set as rigid bodies. Its reduction is set to 30 mm .

[0077] From the strain cloud diagram in the simulation results, select the node between the two unit bodies in the middle of the thick plate, and obtain by measurement: the elastic height of the tensile zone of the model when the reduction is 30mm y 1 for 2.10 mm , the elastic height in the compression zone y 2 is 7.47mm, the simulated neutral layer offset can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com