Control rod driving device of open reactor

A driving device and control rod technology, which is applied in the control of nuclear reactions, reactors, and greenhouse gas reduction, etc., can solve the problems of complex structure of the control rod driving device, complicated structure, easy failure of the rod drop function, etc., to achieve simple structure and ensure safety. , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

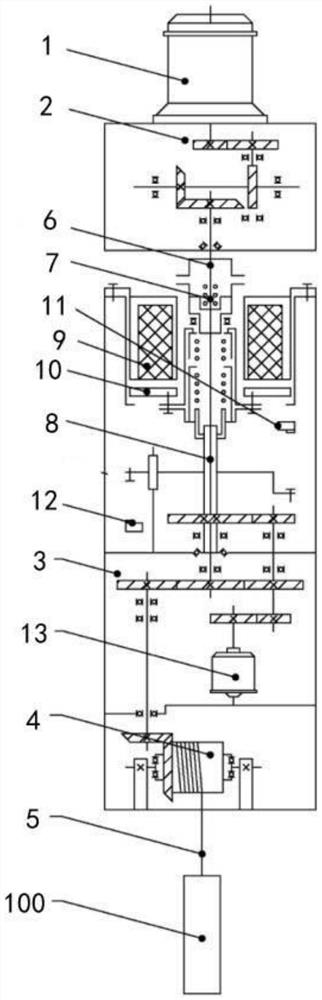

[0047] A control rod driving device for an open reactor includes a driving motor 1 , an upper speed reducer 2 , a brake assembly, a lower speed reducer 3 , a winch 4 and a wire rope 5 .

[0048] The torque input end of the upper reducer 2 is connected with the torque output end of the driving motor 1;

[0049] The torque input end of the brake assembly is connected to the torque output end of the upper reducer 2;

[0050] The torque input end of the lower reducer 3 is connected with the torque output end of the brake assembly;

[0051] The upper reducer 2 and the lower reducer 3 can adopt the existing reducer at the present stage. The reducer is an independent component composed of a gear drive, a worm drive, and a gear-worm drive enclosed in a rigid shell. It is often used as the original The reduction transmission device between the moving part and the working machine. It plays the role of matching speed and transmitting torque between prime mover and working machine or ac...

Embodiment 2

[0058]The structure in the first embodiment realizes the driving of the control rods 100, so that it can be installed in an open reactor, but if a power failure occurs, the rods need to be dropped automatically quickly to improve safety, which is realized by the brake assembly. Yes, the brake assembly includes an upper friction plate 6, a lower friction plate 7, a brake spindle 8 and a safety control assembly.

[0059] The upper friction plate 6 is arranged horizontally, and the rotating shaft of the upper friction plate 6 is fixedly connected with the torque output shaft of the upper reducer 2;

[0060] The lower friction plate 7 is arranged below the upper friction plate 6, and is coaxial and parallel to the upper friction plate 6;

[0061] The outer surface of the brake main shaft 8 is provided with an axial key, and the lower friction plate 7 is provided with a keyway adapted to the key, and the lower friction plate 7 is axially slidably connected with the brake main shaft...

Embodiment 2

[0075] For the second embodiment, in order to prevent the braking main shaft 8 from moving up or down too long and causing damage to the entire driving device, the safety control assembly also includes an upper limit assembly 11 and a lower limit assembly 12 .

[0076] The upper limit assembly 11 is arranged below the assembled armature 10, and when it is in working condition, when the control rod 100 falls to the set minimum position, the upper limit assembly 11 sends a control signal to the control motor 1, and The control motor 1 is stopped, which prevents the control motor 1 from continuously idling.

[0077] The lower limit assembly 12 is arranged above the lower reducer 3. When the control rod 8 is lifted to the set highest position, the lower limit assembly 12 sends a control signal to the control motor 1, and stops the control motor 1, avoiding the control motor 1 continuous idling.

[0078] Both the upper limit assembly 11 and the lower limit assembly 12 in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com