Breeding device for breeding

A body and partition technology, applied in the field of breeding, can solve the problems of high labor intensity, difficult to turn aquatic plants, high water content of aquatic plants, etc., and achieve obvious beneficial effects and suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

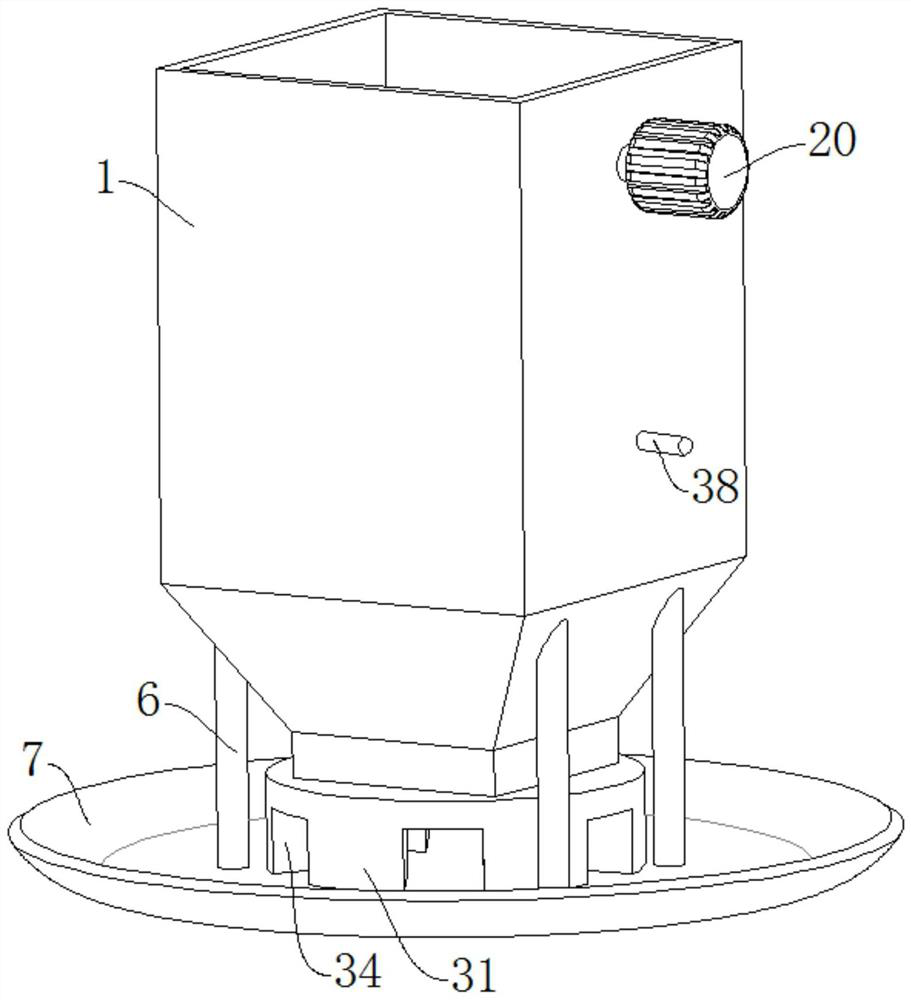

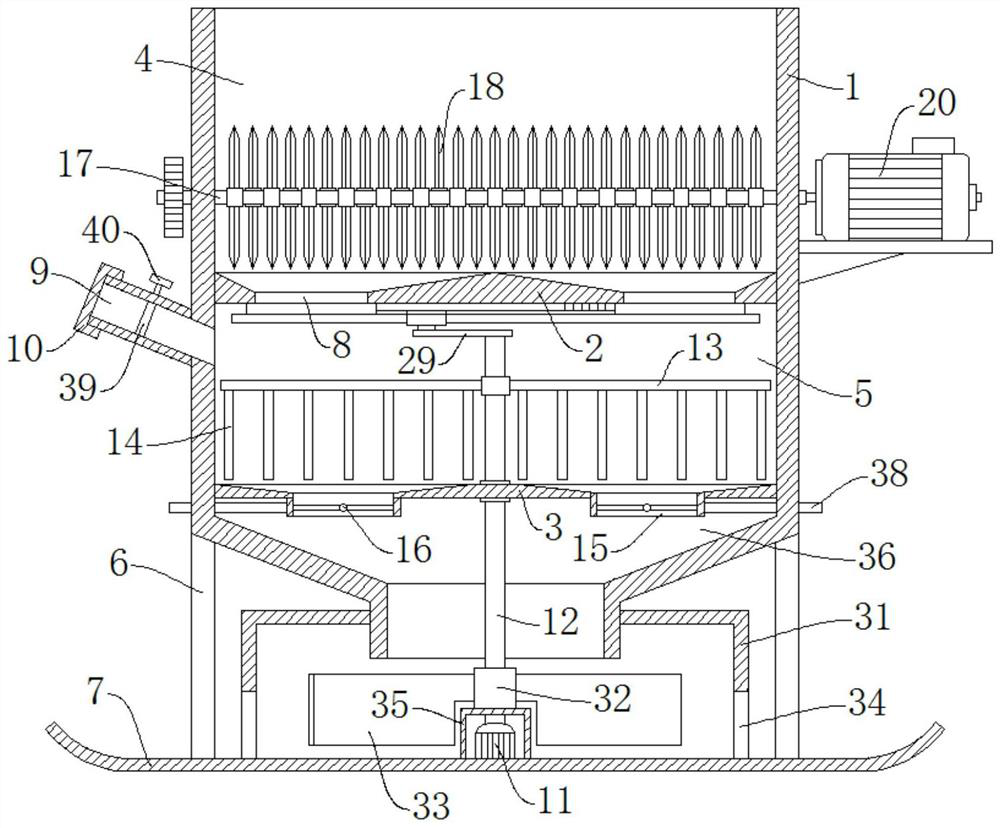

[0027] refer to Figure 1-8 , a breeding device for breeding, comprising a body 1, the body 1 is a quadrangular prism structure with a hollow interior and openings at the upper and lower ends, the bottom of the body 1 is arranged in a pyramid shape, and the bottom of the body 1 is fixedly welded with a support column 6, the support column The bottom end of 6 is fixedly welded with a circular food trough 7, the bottom opening of the body 1 is located directly above the middle of the circular food trough 7, and all the mixture discharged from the bottom of the body 1 falls into the circular food trough 7 for poultry to eat , setting the bottom of the body 1 into a pyramid shape can reduce the residual amount of the mixture at the bottom of the body 1, and the inside of the body 1 is fixedly welded with a first partition 2 and a second partition 3, and the first partition 2 and the second partition The plate 3 divides the inside of the body 1 from top to bottom into a crushing ch...

Embodiment 2

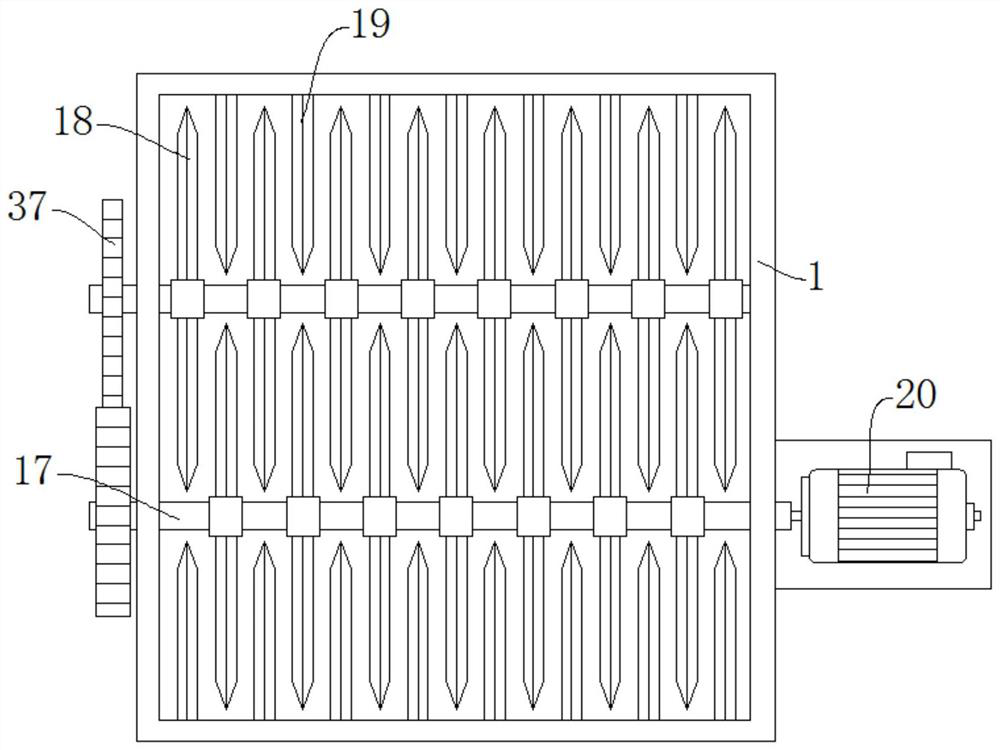

[0032] refer to figure 2 , 3 and 8, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the crushing mechanism includes two horizontal round rods 17 arranged in parallel inside the crushing chamber 4, and the height of the two horizontal round rods 17 is Similarly, a plurality of equally spaced crushing wheels 18 are fixedly welded on the horizontal round rod 17, and the crushing wheels 18 on the two horizontal round rods 17 are arranged at intervals, and positioning cutters 19 are fixedly welded on the two symmetrical inner walls of the body 1. , the positioning cutter 19 is sandwiched between the two crushing wheels 18, and one end of the two horizontal round rods 17 runs through the side wall of the body 1 and extends to the outside of the body 1, and the horizontal round rod 17 outside the body 1 is fixedly installed with a transmission Gear 37, the transmission gear 37 on the two horizontal round rods 17 is engaged and conn...

Embodiment 3

[0034] In Example 1, the aquatic plants crushed by the crushing mechanism will pass through the square groove 8 and enter the mixing chamber 5 to accumulate to form a aquatic plant layer, and then put feed into the mixing chamber 5 through the feed pipe 9 to form a feed layer above the aquatic plant layer. When using the stirring horizontal bar 13 and the stirring vertical bar 14 to stir it, the feed above the water plants will fall into the water plants gap and be fully adhered and mixed with the wet water plants. It contains a lot of water, and the feed texture is dry and it is easy to stick to the aquatic plants, which makes it difficult to mix more feed with the lowest layer of aquatic plants, thus forming a problem that the feed content in the mixture gradually decreases from high to low. To solve this problem We have designed the following technical solutions, refer to Figure 6 and 7 , as another preferred embodiment of the present invention, the difference from Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com