Reaction tower for potassium methoxide production

A technology of reaction tower and potassium methoxide, applied in the field of reaction towers, can solve the problems of wasting the use space of the reaction tower body, impure quality of potassium methoxide, reducing the efficiency of potassium methoxide, etc., so as to improve production rate and product quality, simple structure, and low The effect of input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

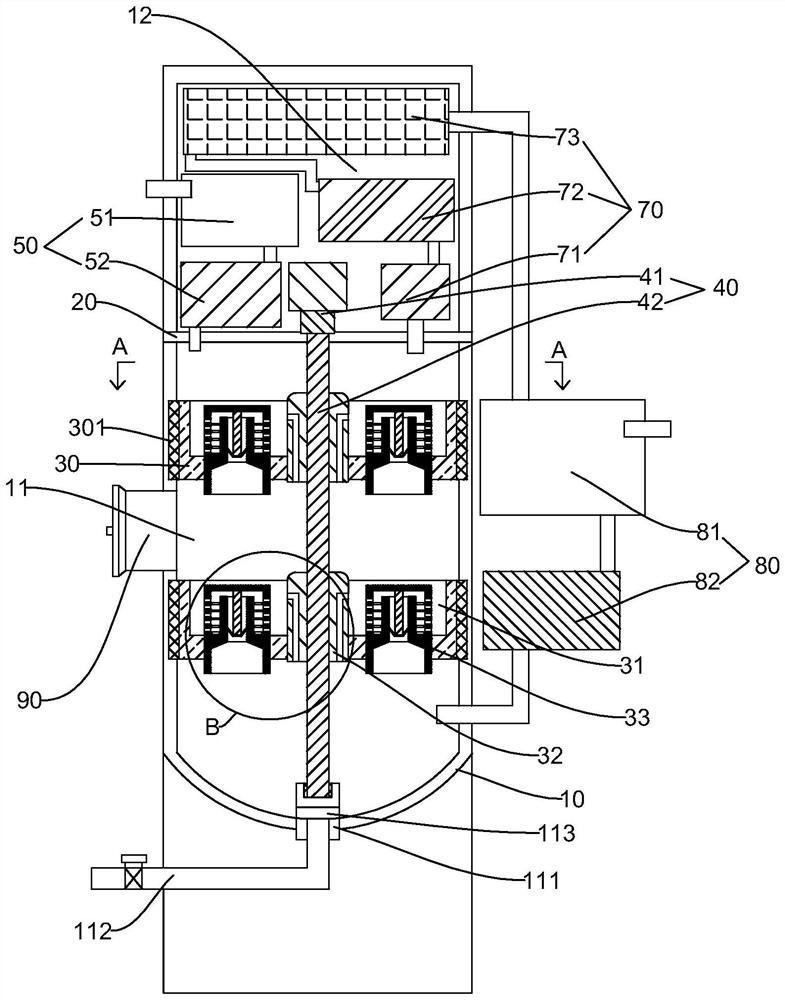

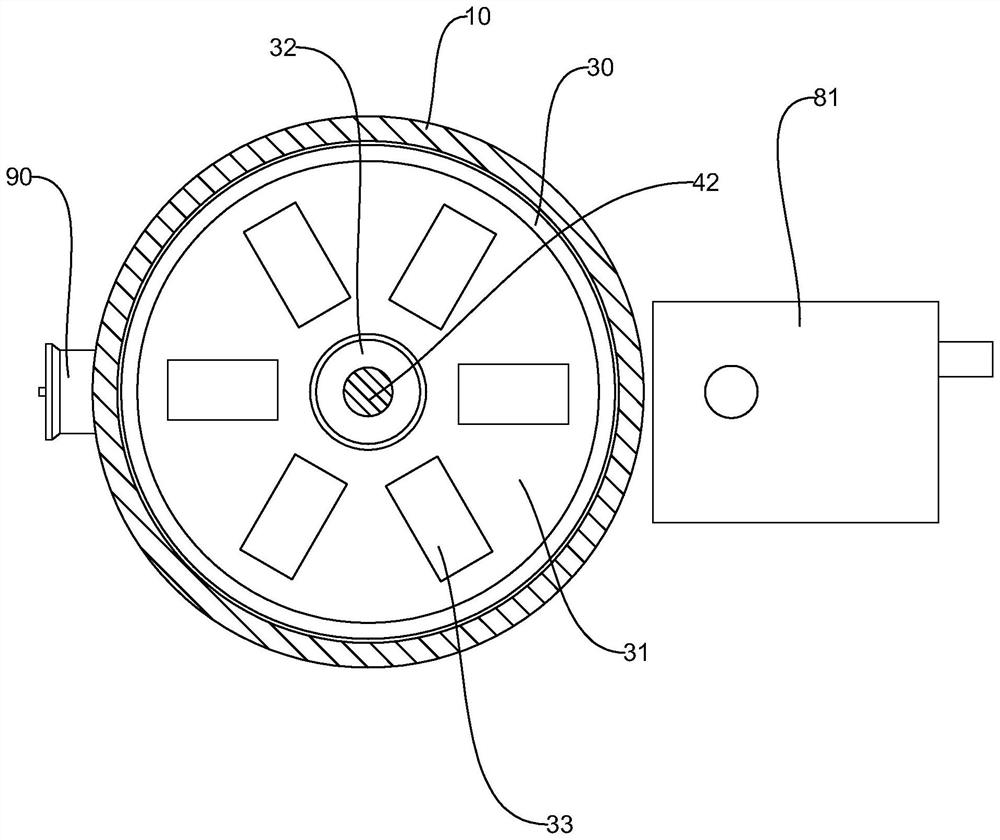

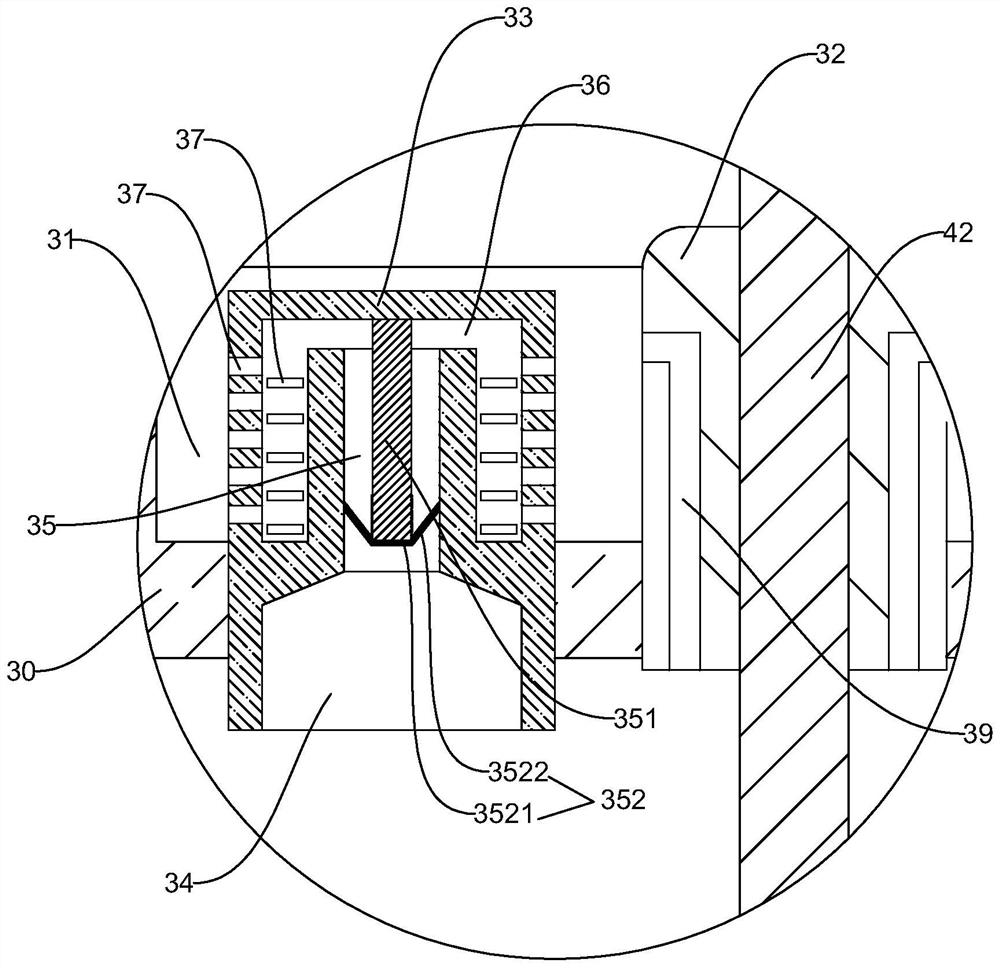

[0017] Depend on Figure 1 to 3 A reaction column for the production of potassium methoxide, comprising a reaction tower body 10 and a methanol evaporation assembly 80, and the reaction tower body 10 is provided with a separator 20, the separator 20 to the reaction tower body. The internal portion of 10 is a first cavity 11 and a second cavity 12, and a plurality of turntables 30 are rotated in the first cavity 11, the plurality of turntables 30 along the axis of the first cavity 11. The direction interval is provided, and each of the turntable 30 is provided with a reaction groove 31, and the reaction groove 31 is provided with a bump 32 and a plurality of stirring blocks 33, and the bumps 32 are set to the turntable 30. The plurality of stirring blocks 33 are disposed about the axial direction of the turntable 30, and each of the first end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com