Embossing processing mold for automobile artificial leather

A technology for artificial leather and processing molds, applied in the field of automotive artificial leather processing, can solve the problems of easy to produce sliding, affecting the embossing effect of artificial leather, and inability to accurately control the pressure, and achieve the effect of improving the embossing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

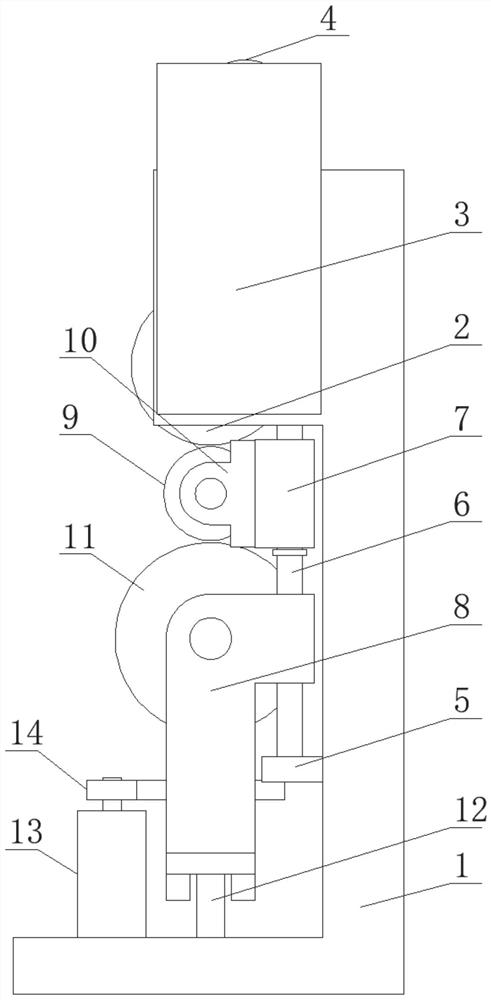

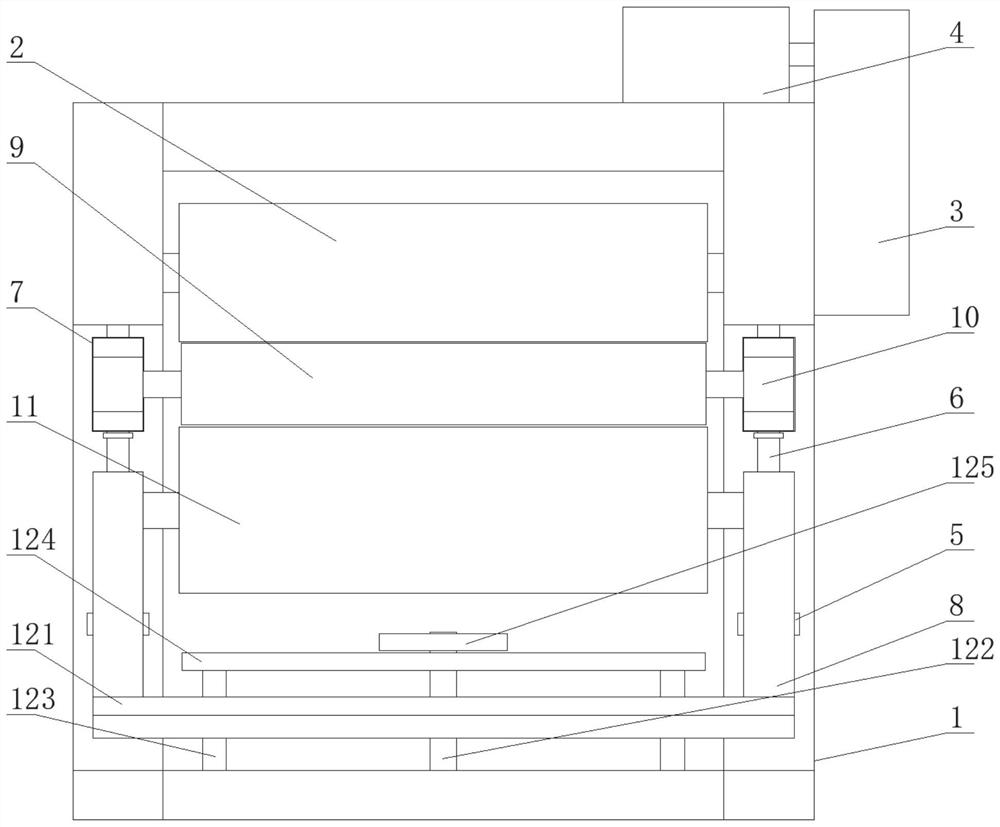

[0015] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

[0016] The drawings in the embodiments of the present invention: the different types of section lines in the drawings are not marked according to the national standard, and there is no requirement for the material of the components, but to distinguish the cross-sectional views of the components in the drawings.

[0017] see Figure 1-2 , the embossing mold of automobile artificial leather, including frame 1, the drive roller 2 that is rotatably connected to the inside of frame 1, the reduction box 3 that is fixedly installed on the outside of frame 1 and is connected with the drive rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com