Intelligent loading and unloading system

A loading and unloading system, intelligent technology, applied in the direction of transportation and packaging, conveyor control devices, conveyors, etc., to achieve the effect of reducing errors in grabbing battery boxes, intelligently grabbing and transporting items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

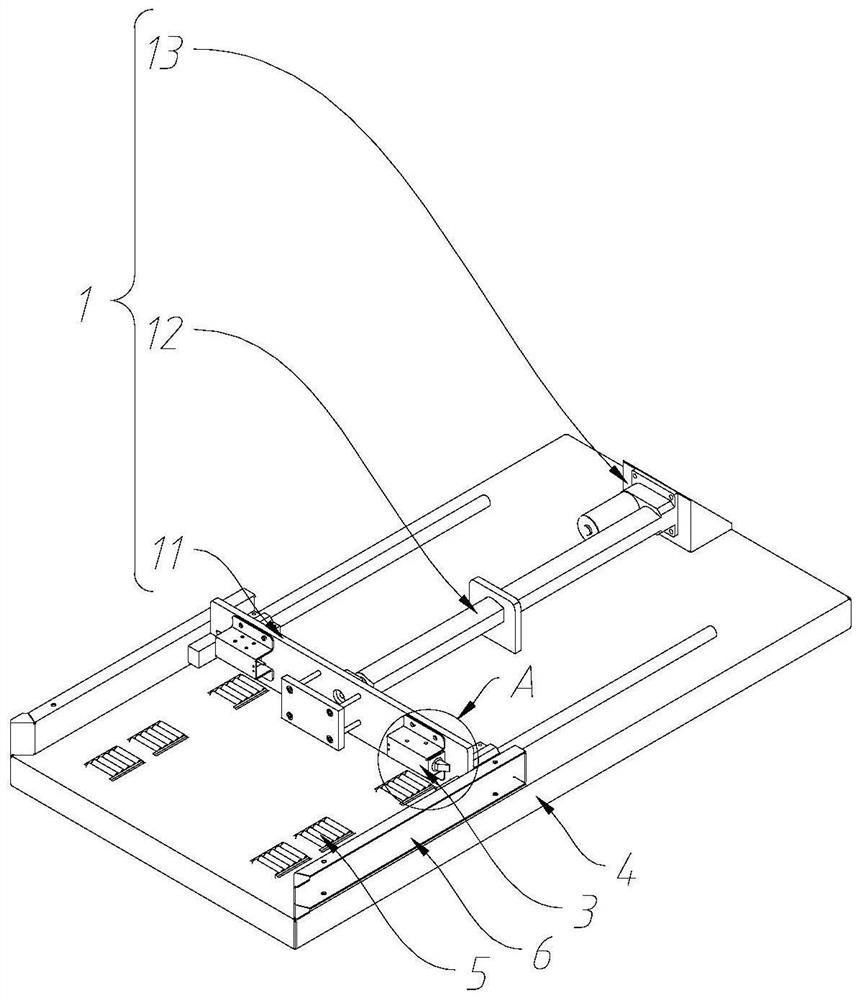

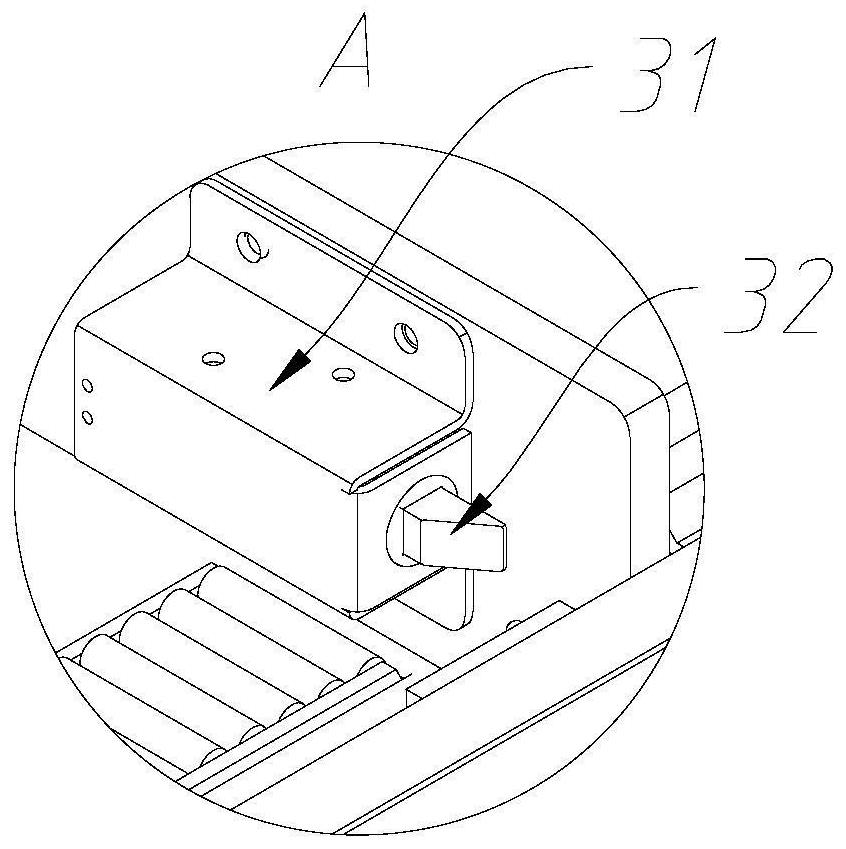

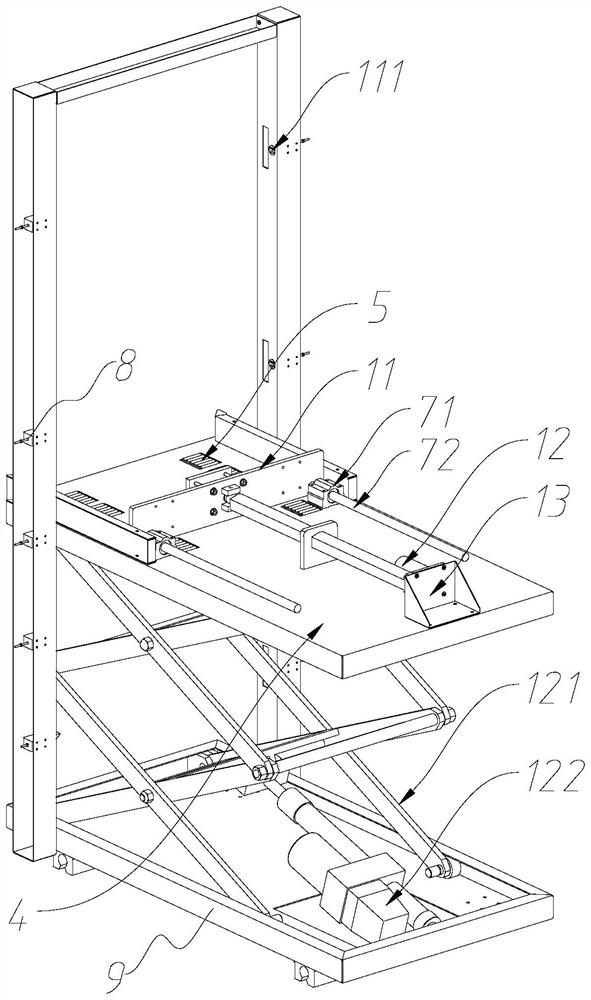

[0040] See for details Figure 1 to Figure 8 , the present invention discloses an intelligent loading and unloading system. It is hereby explained that the battery box is used as an example in this solution, but it is not limited to the battery box. It is also applicable to the logistics box used to transport items. Logistics cabinet; the intelligent loading and unloading system includes a control unit, a moving mechanism 10, a fixed base 9 with several first positioning detection units 8 from top to bottom, a liftable loading and unloading mechanism and some second positioning detection units, and the loading and unloading mechanism is installed on Inside the fixed base 9, the fixed base 9 is connected to the moving mechanism 10, the second positioning detection unit is arranged on the moving mechanism 10 or is arranged on one side of the moving mechanism 10, the first positioning detection unit 8, the second positioning detection unit, the loading and unloading mechanism and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com