Knitted elastic braid capable of being stretched at any angle and preparation method of knitted elastic braid

An arbitrary angle and elastic technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of uneven wearing feeling of fabrics, leaving marks and red marks, uncomfortable and unsightly, etc. Good body sculpting effect and good market economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Below in conjunction with accompanying drawing, the present invention is further described:

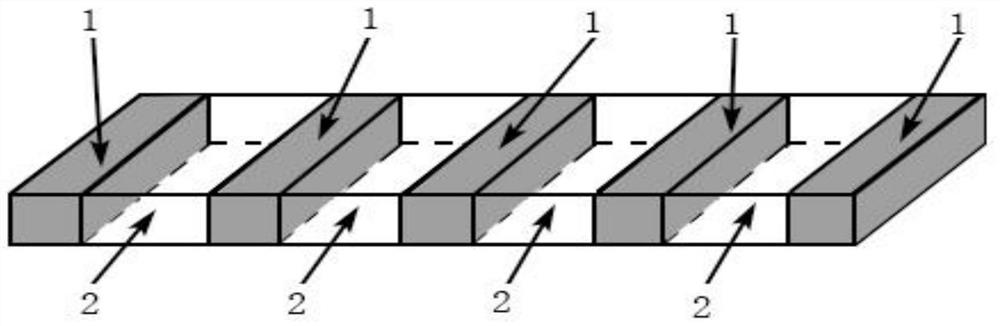

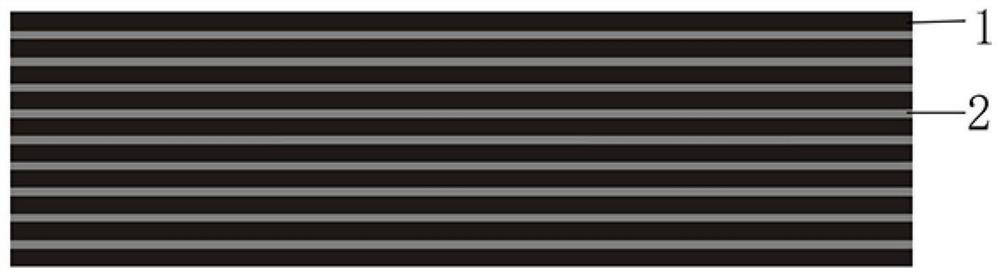

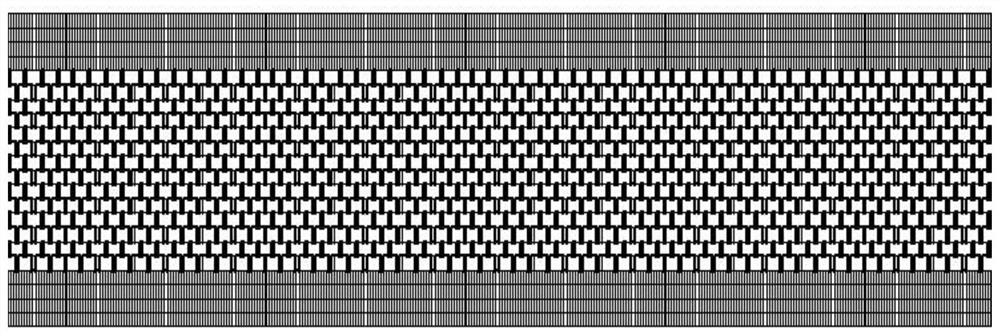

[0029] Such as figure 1 , figure 2 As shown, the knitted elastic webbing includes a webbing main body formed by integral weaving of warp and weft yarns; the webbing main body includes webbing sub-body and stretching comfort zone spaced apart from each other; the stretching comfort zone can be pulled to any angle along with the direction of force stretch. The woven tape body 1 is formed by interweaving warp yarns and weft yarns, and the stretch comfort zone 2 is formed by elastic weft yarns. The warp yarns of the webbing sub-body 1 and the stretch comfort zone 2 are all fine denier yarns, and the raw material of the fine denier yarns is one of nylon, polyester high elastic thread, spandex, and spandex covered yarn. The weft yarn is fine denier spandex or spandex covered yarn.

[0030] The main manufacturing equipment of the present invention adopts the machine platform that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com