Textile fabric preshrinking device with energy-saving and environment-friendly functions

A technology for textile fabrics, energy saving and environmental protection, applied in the field of clothing, can solve problems such as poor wetting and uneven wetting, and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

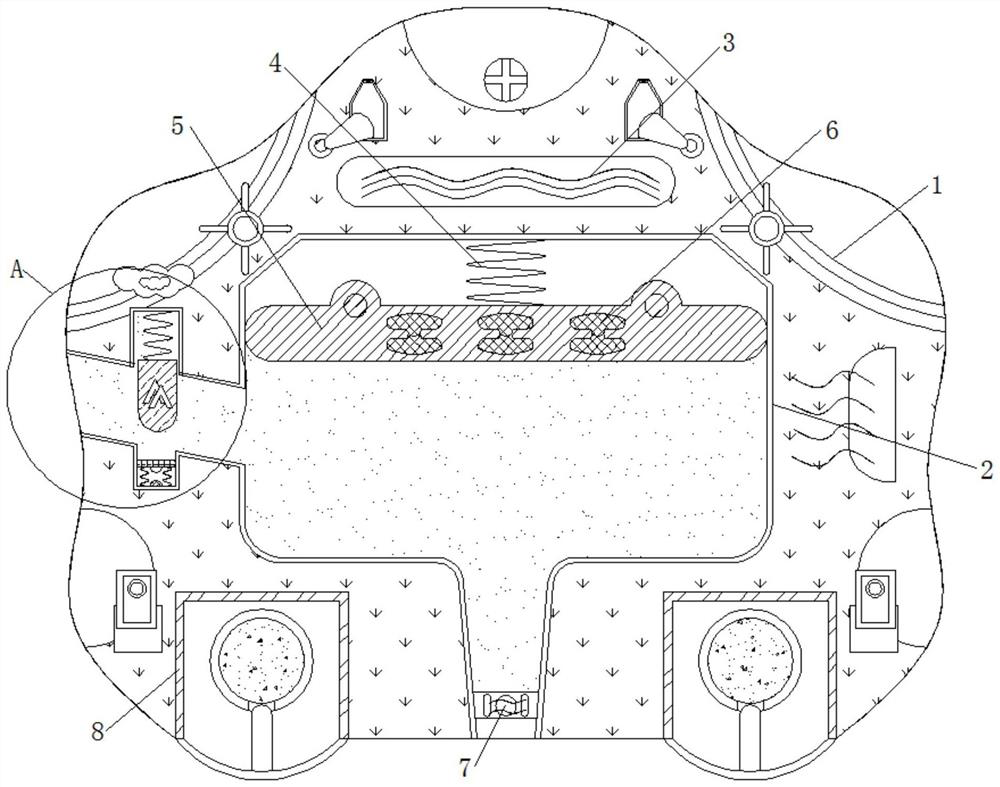

[0026] see figure 1 and figure 2 , a textile fabric pre-shrinking device with energy-saving and environmental protection functions, comprising a body 1, the inner wall of the body 1 is fixedly connected with a liquid storage chamber 2, and the inner wall of the body 1 is fixedly connected with an electromagnet-3 near the top of the liquid storage chamber 2, The top of the inner wall of the liquid storage chamber 2 is fixedly connected with a spring 4, the bottom of the spring 4 is fixedly connected with an extrusion block 5, the inner wall of the extrusion block 5 is fixedly connected with a magnetic block 6, and the bottom of the inner wall of the liquid storage chamber 2 is fixedly connected with There is a water outlet valve 7, a control assembly 8 is fixedly connected to the bottom of the inner wall of the body 1, and a movable assembly 9 is fixedly connected to the inner wall of the body 1 near the left side of the liquid storage chamber 2;

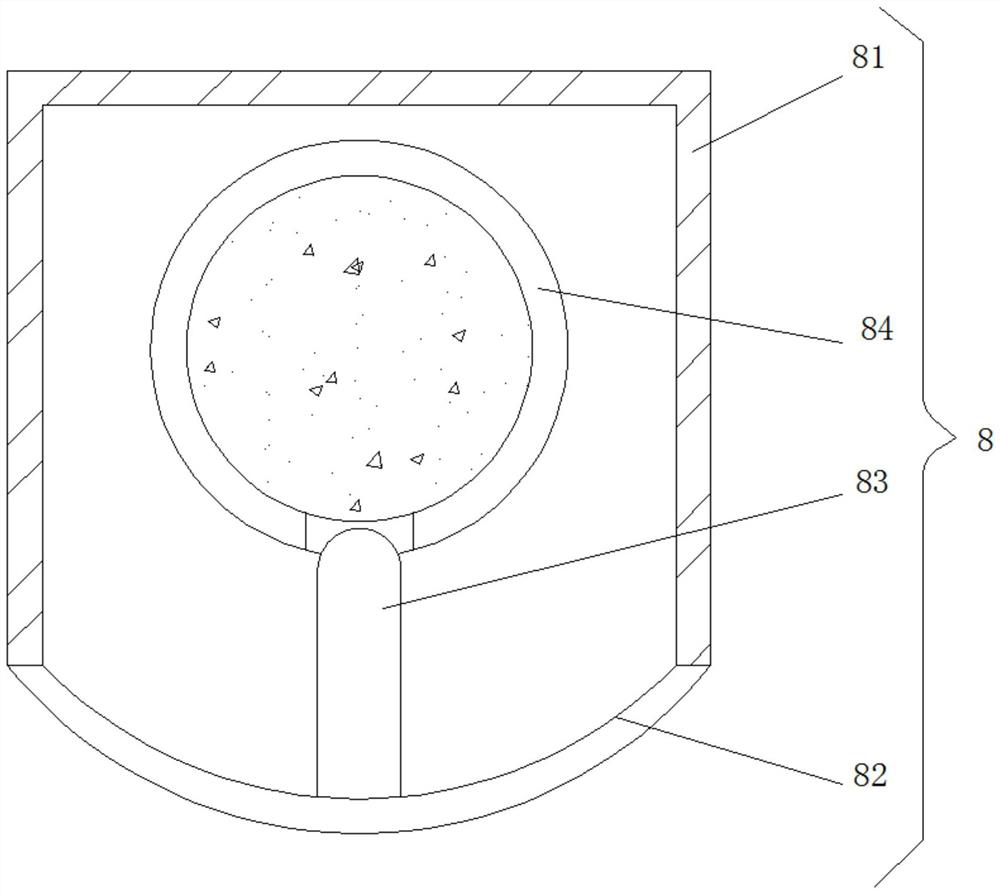

[0027] The control assembly...

Embodiment 2

[0029] see figure 1 and image 3 , a textile fabric pre-shrinking device with energy-saving and environmental protection functions, comprising a body 1, the inner wall of the body 1 is fixedly connected with a liquid storage chamber 2, and the inner wall of the body 1 is fixedly connected with an electromagnet-3 near the top of the liquid storage chamber 2, The top of the inner wall of the liquid storage chamber 2 is fixedly connected with a spring 4, the bottom of the spring 4 is fixedly connected with an extrusion block 5, the inner wall of the extrusion block 5 is fixedly connected with a magnetic block 6, and the bottom of the inner wall of the liquid storage chamber 2 is fixedly connected with There is a water outlet valve 7, a control assembly 8 is fixedly connected to the bottom of the inner wall of the body 1, and a movable assembly 9 is fixedly connected to the inner wall of the body 1 near the left side of the liquid storage chamber 2;

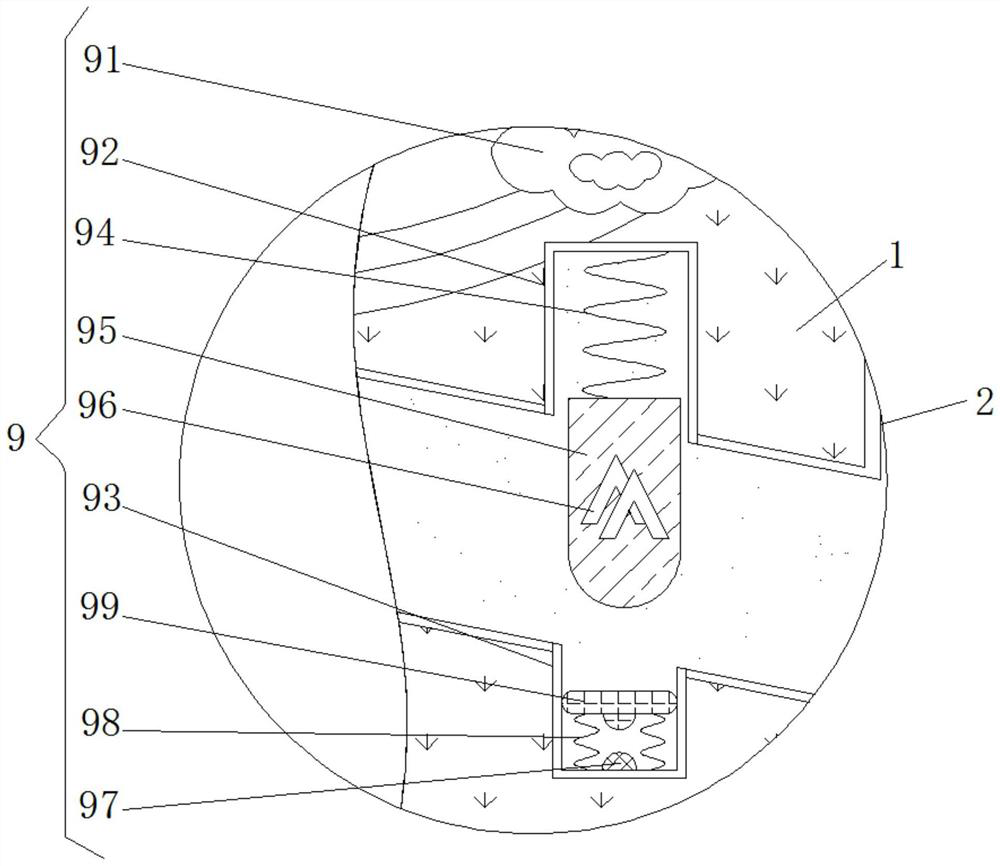

[0030] Movable assembly 9 co...

Embodiment 3

[0033] see Figure 1-4 , a textile fabric pre-shrinking device with energy-saving and environmental protection functions, comprising a body 1, the inner wall of the body 1 is fixedly connected with a liquid storage chamber 2, and the inner wall of the body 1 is fixedly connected with an electromagnet-3 near the top of the liquid storage chamber 2, The top of the inner wall of the liquid storage chamber 2 is fixedly connected with a spring 4, the bottom of the spring 4 is fixedly connected with an extrusion block 5, the inner wall of the extrusion block 5 is fixedly connected with a magnetic block 6, and the bottom of the inner wall of the liquid storage chamber 2 is fixedly connected with There is a water outlet valve 7, a control assembly 8 is fixedly connected to the bottom of the inner wall of the body 1, and a movable assembly 9 is fixedly connected to the inner wall of the body 1 near the left side of the liquid storage chamber 2;

[0034] The control assembly 8 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com