Tablet online sampling detection control system and tablet quality detection system

A detection control system, tablet technology, applied in measuring devices, manufacturing tools, instruments, etc., can solve problems such as increasing failure rate, time lag, individual operation differences, and inability to detect quality abnormalities in time, and achieve scientific detection. Reasonable and improve the effect of abnormal situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

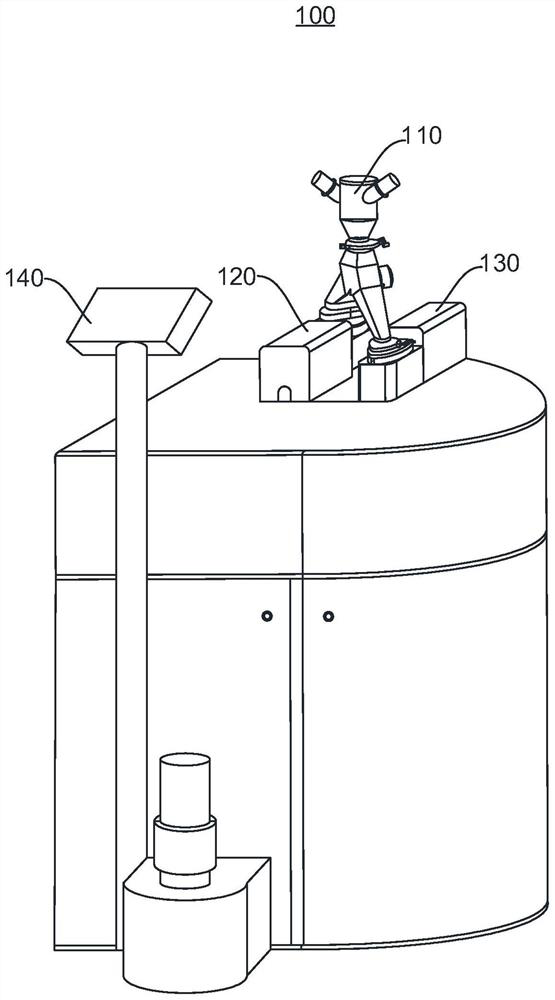

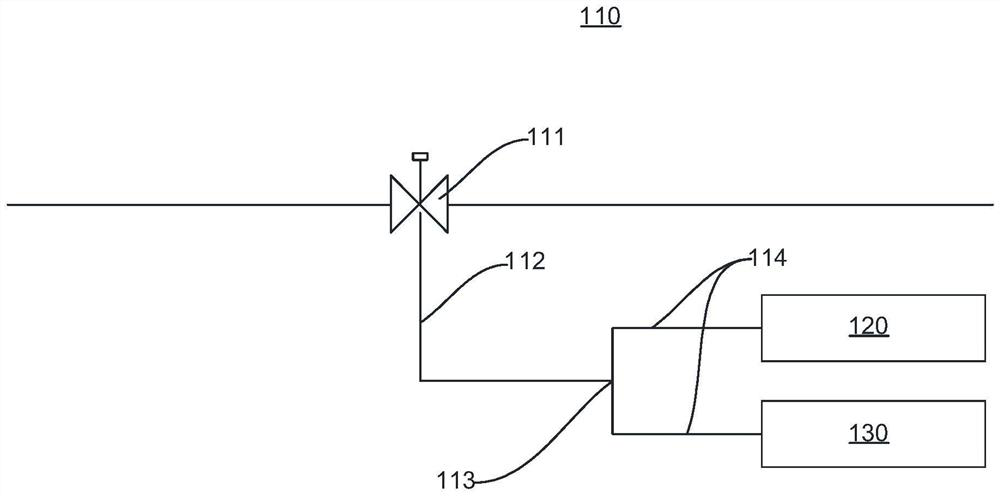

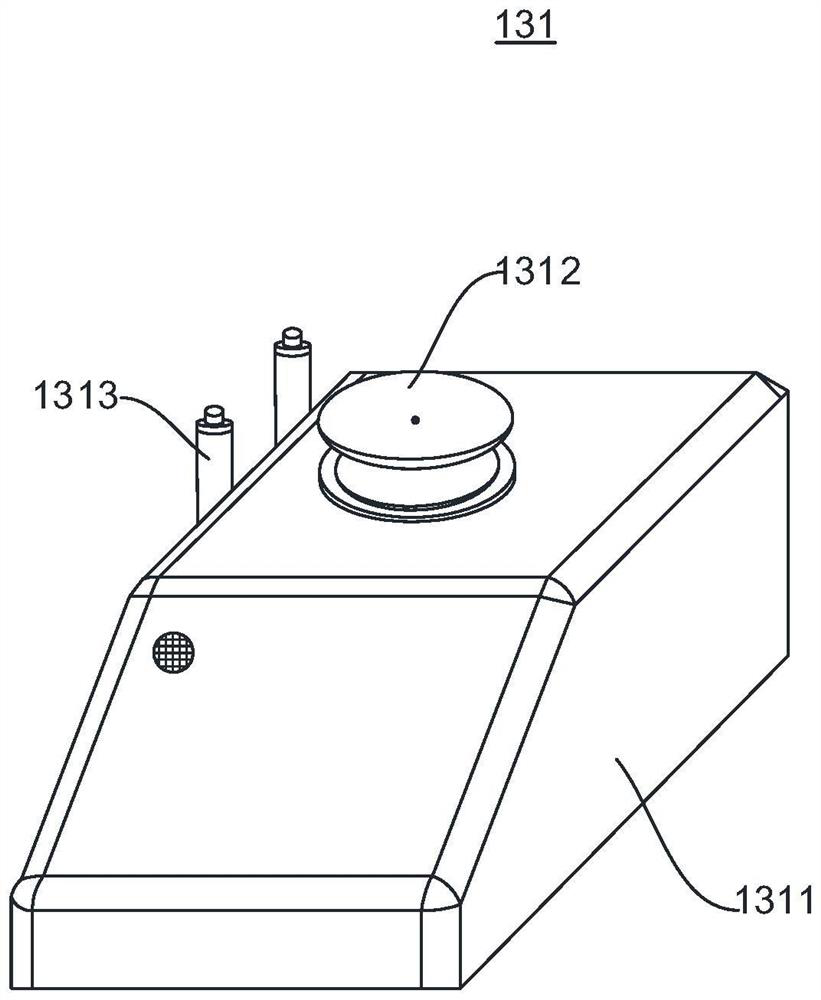

[0045] Please refer to figure 1 , this embodiment provides an online tablet sampling and testing control system 100, which is suitable for sampling and testing the tablets discharged from the tablet press and controlling the operating parameters of the tablet press according to the test results. Specifically, the tablet online sampling detection control system 100 of the present application includes an automatic sampling mechanism 110, a group weighing mechanism 120, a single particle detection mechanism 130 and a control mechanism 140, and the discharge port of the automatic sampling mechanism 110 is connected to the group weighing mechanism 120. The feed port is connected with the feed port of the single-grain detection mechanism 130, the unqualified product discharge port of the group weighing mechanism 120 is connected with the feed port of the single-grain detection mechanism 130, the automatic sampling mechanism 110, the group weighing mechanism 120, the single-grain The...

Embodiment 2

[0062] see Figure 7 , this embodiment provides a tablet quality detection system, which includes the tablet online sampling detection control system 100 of Embodiment 1.

[0063] Further, the tablet quality inspection system of this embodiment also includes a tablet press, a device to be released, a finished product material barrel, a waste material barrel, a tablet screening machine and a metal detector.

[0064] The tablet press is equipped with a self-inspection mechanism, and the self-inspection mechanism is equipped with a self-inspection qualified pipeline and a self-inspection unqualified pipeline. The self-inspection qualified pipeline is connected to the finished material barrel, and the self-inspection unqualified pipeline is connected to the waste barrel;

[0065] The tablet on-line sampling detection control system 100 is communicated with the self-inspection qualified pipeline and conducts sampling inspection on the tablets on the self-inspection qualified pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com