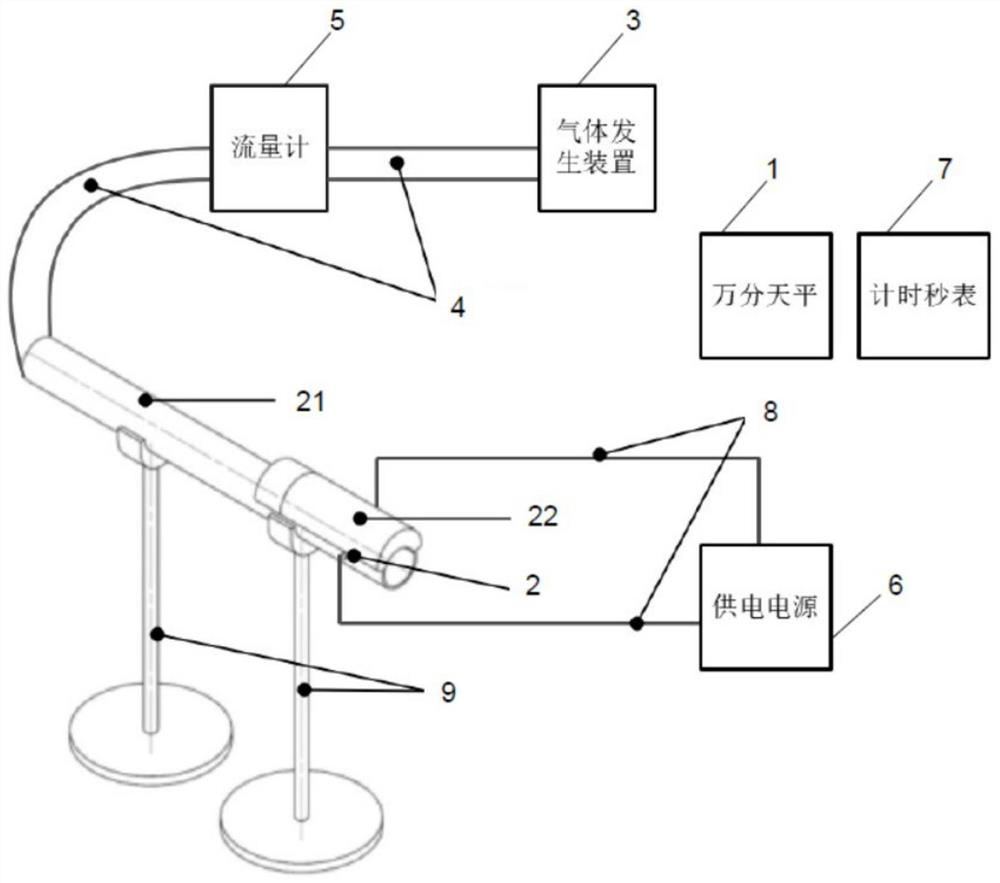

Electronic cigarette atomization core tobacco juice consumption rate testing system and method

An electronic cigarette and rate testing technology, applied in the field of electronic cigarettes, can solve the problems of cumbersome operation process, difficult to achieve fast and accurate measurement, poor accuracy, etc., and achieve the effect of good test repeatability, satisfying experimental research needs, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

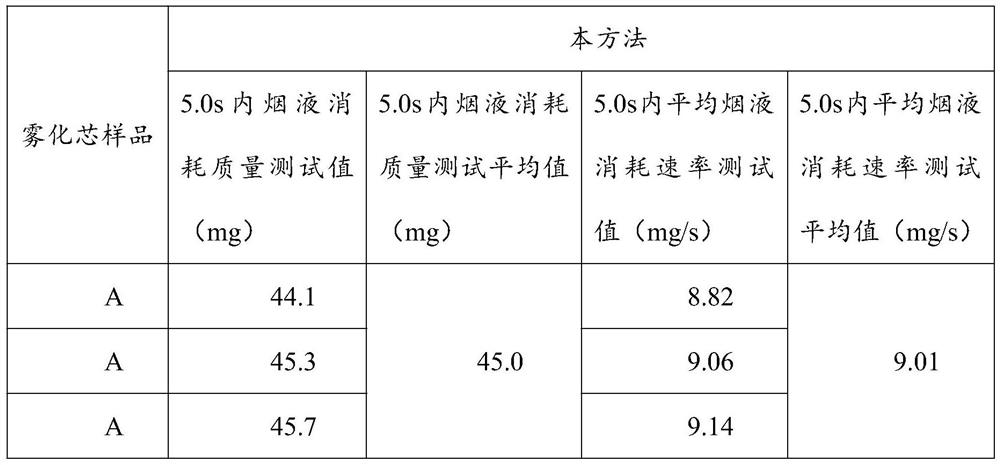

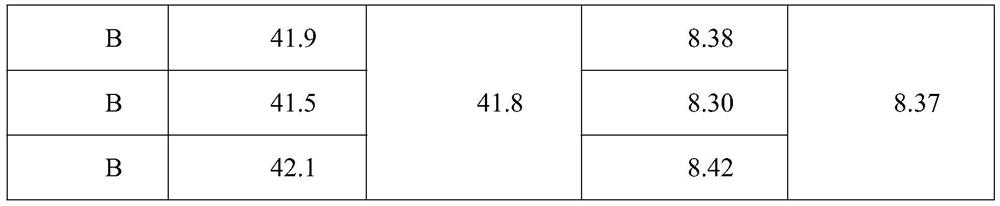

Embodiment 1

[0072] Embodiment 1 provides a method for testing the consumption quality of atomizing core smoke liquid, the test method includes the following steps:

[0073] Step 1. Take out the test atomizing core sample A from the brand-new pod, fully soak and rinse the removed atomizing core with absolute ethanol for 30 minutes, then take it out and fully dry it, then turn on the micro balance, and weigh it Measure the mass of the atomizing core, denoted as m 0 , accurate to 0.1mg;

[0074] Step 2. Turn on the micrometer balance, put a cut double-sided smooth Teflon paper in the center of the micrometer balance, then reset the micrometer balance to zero, and then weigh 75.8mg of e-liquid on the paper piece (75.8 mg does not exceed the maximum smoke liquid mass that atomization core sample A can absorb);

[0075] Step 3. Put the dried atomizing core sample A into the left half of the atomizing core fixing device, and do not package the fixing device temporarily, and then tilt the Teflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com