Novel biological foodstuff blending device

A biological and food material technology, applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve problems such as simple structure, low work efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

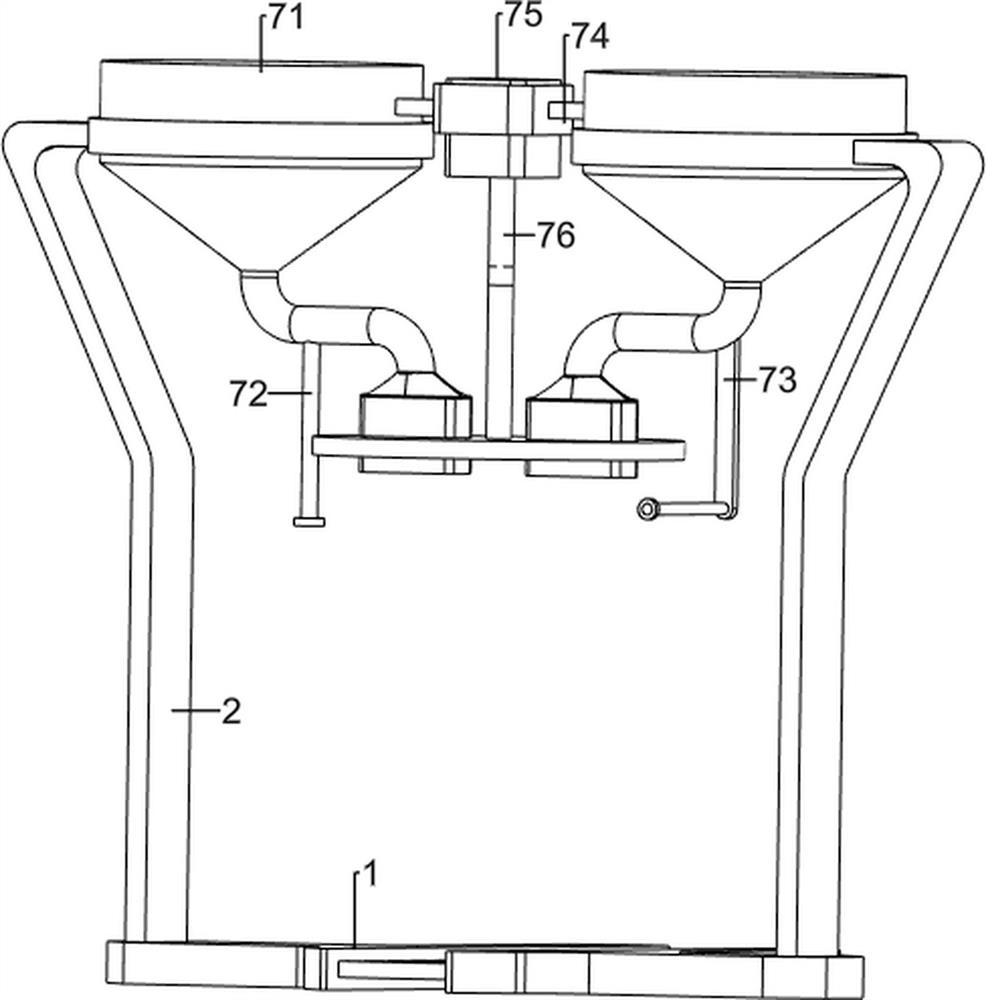

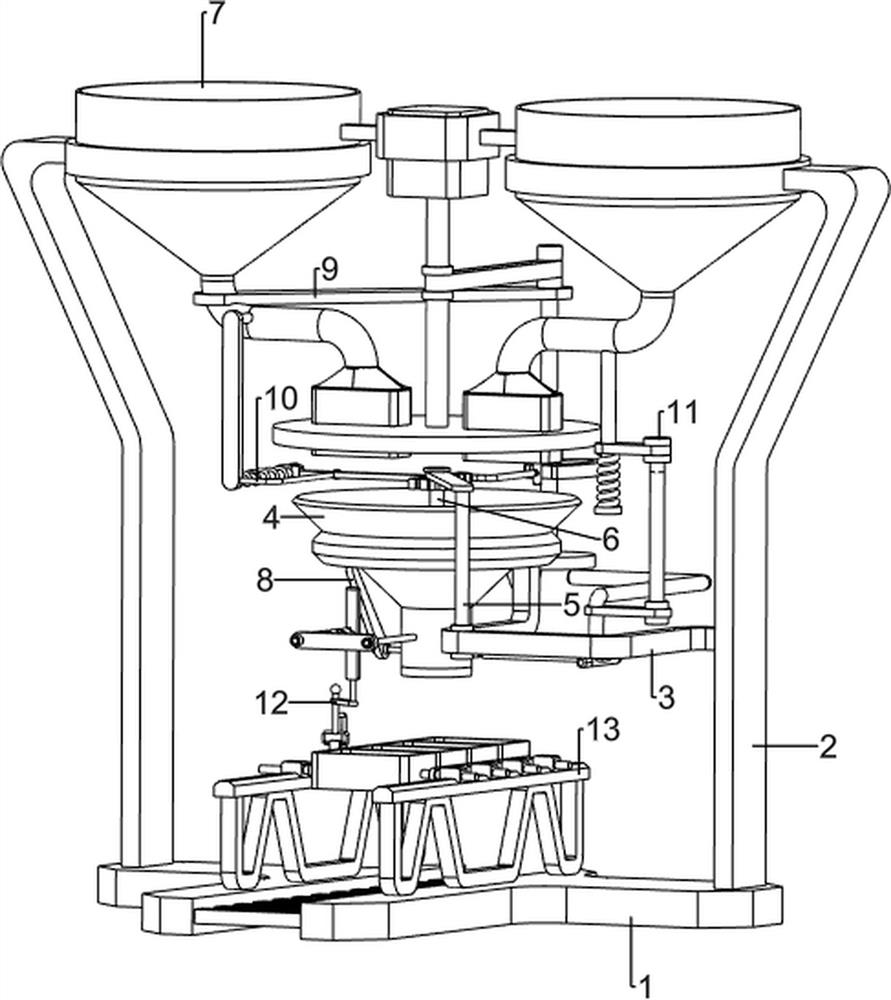

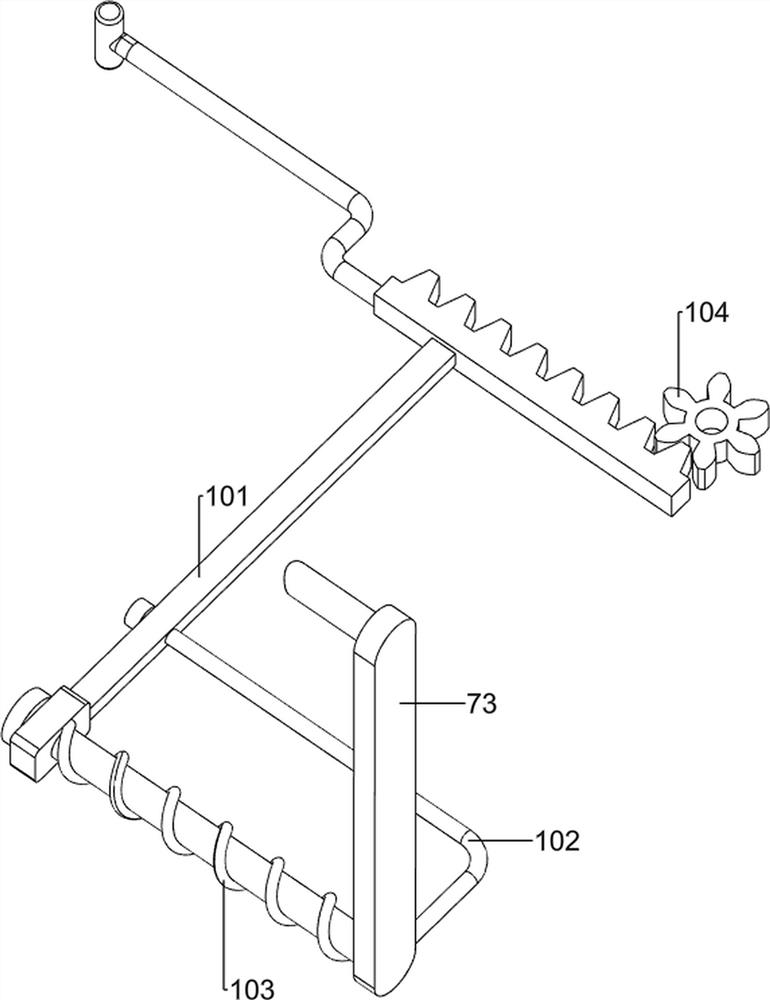

[0031] A novel biological food preparation device, such as figure 1 , figure 2 and image 3 As shown, it includes a first support plate 1, a first support frame 2, a first support rod 3, a stirring frame 4, a second support rod 5, an agitator 6, an intermittent feeding mechanism 7, a discharge box 71, a third Support rod 72, the second support frame 73, the first fixed frame 74, motor 75, rotating blanking rack 76, opening and closing mechanism 8, rotating post 81, opener 82, the first torsion spring 83, long plate 84, rotating Mechanism 9, first connecting fixed plate 91, rotating shaft 92, transmission assembly 93, cam 94, ball block 95, stirring driving mechanism 10, rack bar 101, stabilizing bar 102, first spring 103, gear 104, pressing mechanism 11 , the second fixed frame 111, the second spring 112, the presser 113, the pushing mechanism 12, the third fixed frame 121, the long plate frame 122, the third spring 123, the pushing frame 124, the pushing block 125, the sec...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 and Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the bottom of the discharge box 71 on the left side is provided with a first connecting fixed plate 91, and the inner side of the first connecting fixed plate 91 is rotated to be provided with a rotating shaft 92, and a transmission is connected between the rotating shaft 92 top and the rotating blanking frame 76. Assembly 93, transmission assembly 93 is made up of two belt pulleys and a belt, and a belt pulley is connected on the rotating unloading frame 76, and another belt pulley is connected on the rotating shaft 92, and belt is connected between two pulleys, and rotating shaft 92 bottoms are provided with The cam 94 and the bottom of the rotating shaft 92 are provided with a ball block 95 .

[0037] The second support frame 73 is provided with a rack bar 101 slidingly, and the rack bar 101 cooperates with the cam 94. The second support frame 73 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com