Intelligent guniting robot

A robot and spraying technology, which is applied in the direction of manipulators, spraying devices, manufacturing tools, etc., can solve problems such as the inability to keep the spray gun vertical, many safety hazards, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

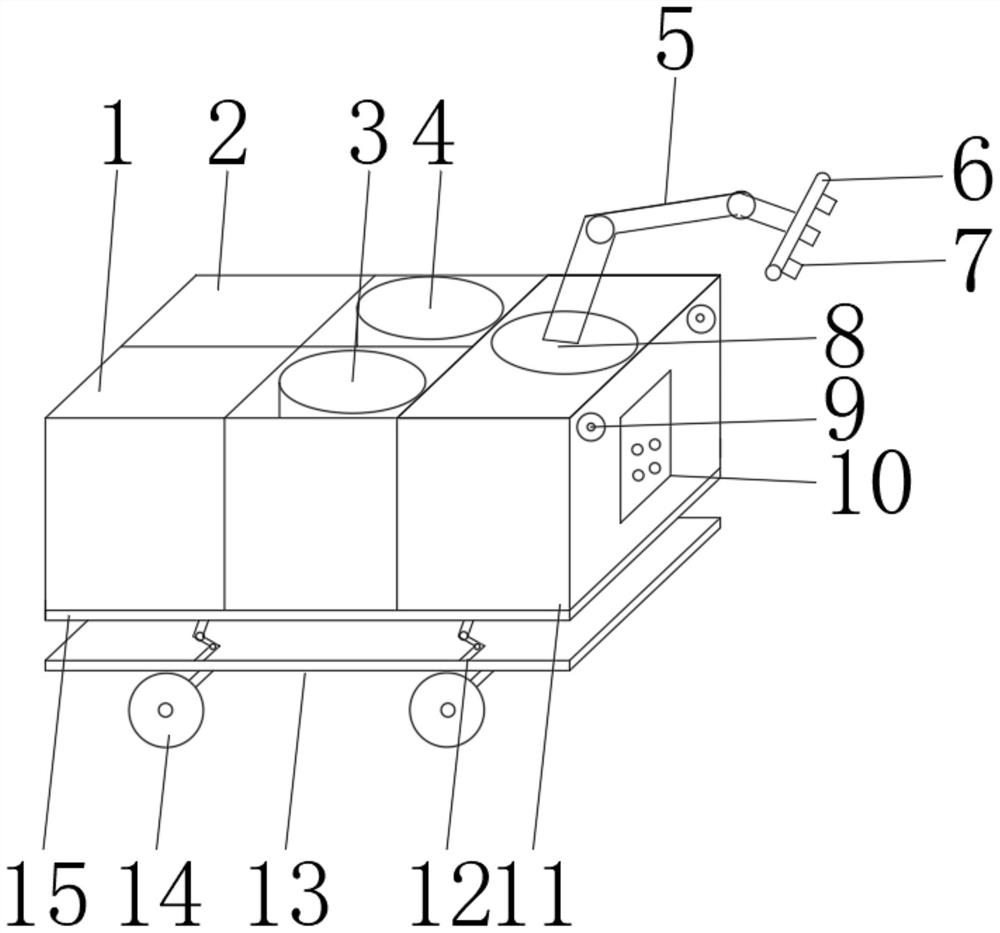

Embodiment 1

[0029]An intelligent spraying robot, including other storage area 1, spare parts storage area 2, slurry box 11 and base plate 13, a supporting plate 15 is installed above the base plate 13, and a lifting device 12 is evenly installed between the base plate 13 and the supporting plate 15 , the lifting device 12 can realize the lifting of the equipment to be suitable for spraying operations at different heights, and is suitable for spraying heights of 0-4.5m; Scissor type, guide rail type and other forms, the power source can be hydraulic, pneumatic, electric, etc., one end of the pallet 15 is installed with a slurry box 11, and the inside of the slurry box 11 is equipped with precise positioning equipment, and it is connected with the on-site positioning system. Compatible to realize the precise positioning of the spraying robot. The agitator can be installed inside the slurry box 11 according to the slurry mixing requirements for manual mixing or automatic mixing. Before the sl...

Embodiment 2

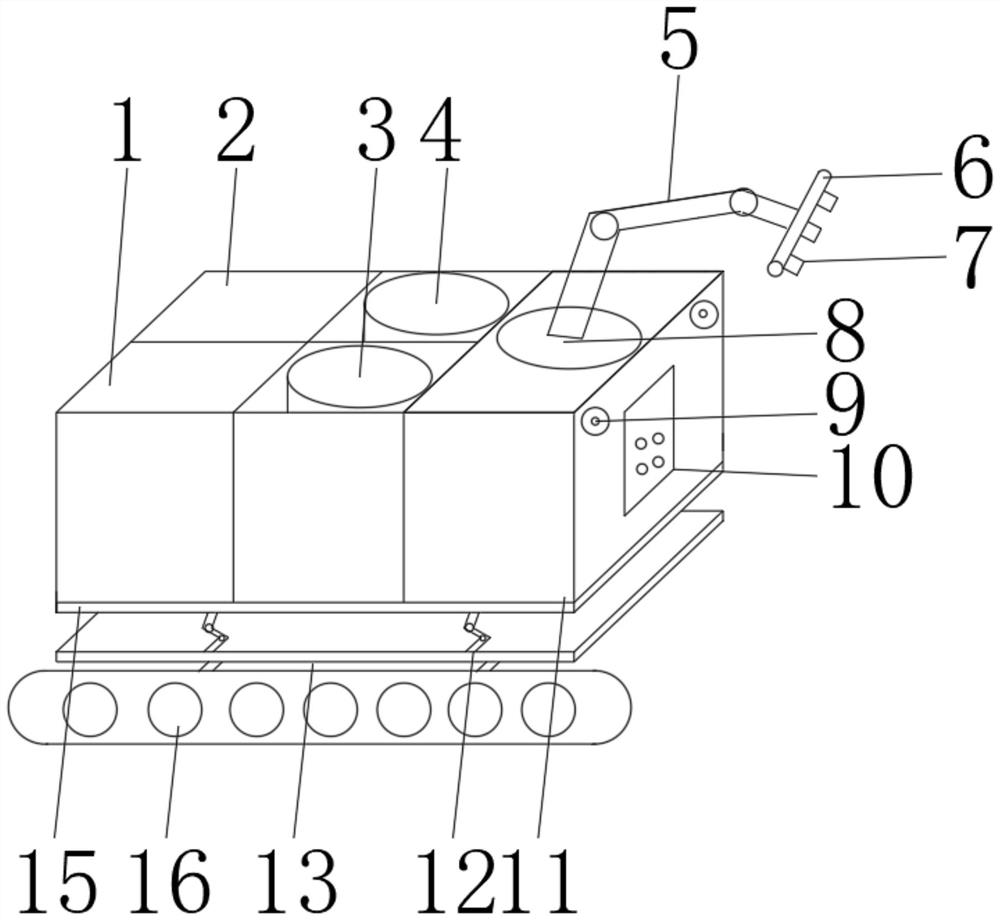

[0032] An intelligent spraying robot, including other storage area 1, spare parts storage area 2, slurry box 11 and base plate 13, a supporting plate 15 is installed above the base plate 13, and a lifting device 12 is evenly installed between the base plate 13 and the supporting plate 15 , the lifting device 12 can realize the lifting of the equipment to be suitable for spraying operations at different heights, and is suitable for spraying heights of 0-4.5m; Scissor type, guide rail type and other forms, the power source can be hydraulic, pneumatic, electric, etc., one end of the pallet 15 is installed with a slurry box 11, and the inside of the slurry box 11 is equipped with precise positioning equipment, and it is connected with the on-site positioning system. Compatible to realize the precise positioning of the spraying robot. The inside of the slurry box 11 can be installed with a mixer according to the slurry mixing requirements, for manual mixing or automatic mixing. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com